How to Reduce Cosmetic Packaging Costs Without Sacrificing Quality?

July 10, 2025 • Mike Lee

Feeling the pinch of rising packaging costs? You're not alone. High-quality packaging is essential, but it shouldn't break the bank.

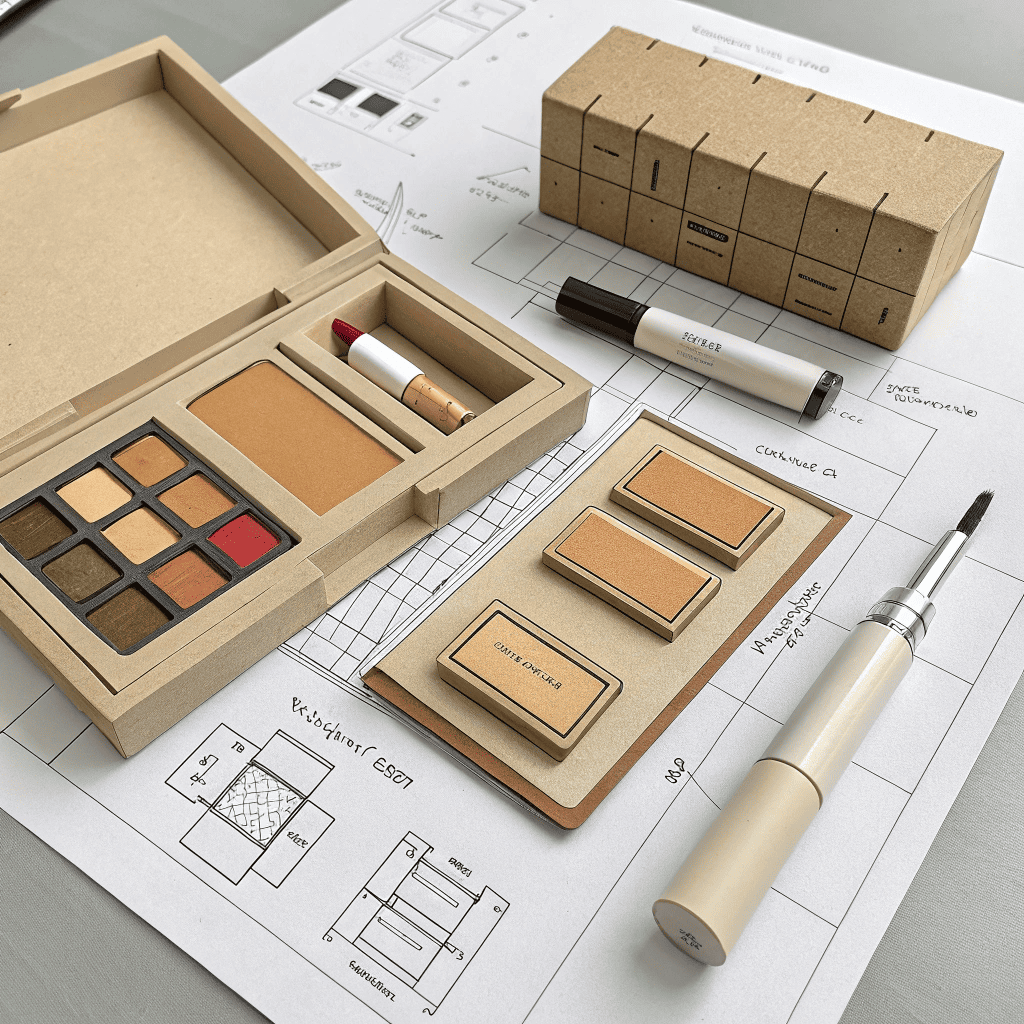

Reducing cosmetic packaging costs without sacrificing quality involves smart design, material choices, and supply chain management. Focus on simple designs, eco-friendly materials like recycled cardboard, and building strong supplier relationships. Expert designs which consider the specific cost of each manufacturing process can also drive costs down.

Finding the sweet spot between cost and quality can be tough. But, by digging into some key strategies, it’s possible to create packaging that’s both appealing and affordable. So, let's explore some ways to cut those costs.

How to reduce the cost of packaging?

Worried about escalating packaging expenses? I get it. It's a balancing act to keep your products looking good without emptying your wallet.

To reduce packaging costs, prioritize simple designs, use less material, and switch to cost-effective options like plastic films or recycled cardboard. Bulk ordering and optimizing packaging size for shipping can also help lower expenses.

One way I've found to cut costs is by streamlining the design. A minimalist approach not only reduces the amount of material needed but also lowers printing and labor expenses. Think about it – fewer layers, less ink, and easier assembly all add up to significant savings. Also, choosing the right material is important. Recycled cardboard or kraft paper is awesome because they are budget-friendly and sustainable.

Here's what I've learned about material costs:

| Material | Cost | Sustainability | Uses |

|---|---|---|---|

| Recycled Cardboard | Low | High | Boxes, inserts, protective padding |

| Kraft Paper | Low | High | Labels, wrapping, void fill |

| Plastic Films | Moderate | Low | Wrapping, sealing |

| Glass | High | Moderate | High-end products like serums and essential oils |

Also, consider how your packaging will be transported. Optimizing the shape and size of your packaging can cut down on shipping costs. Compact, stackable designs help minimize space, reducing the overall shipping expenses. For fragile items, nesting or interlocking designs provide better stability and protection, reducing damage-related costs.

How can we reduce the amount of packaging?

Is excessive packaging weighing you down? It's not just about the money; it shows your company's stand on sustainability.

To reduce the amount of packaging, use minimalist designs, eliminate unnecessary layers, and switch to concentrated product formats. Refillable containers and packaging that doubles as storage can also reduce waste.

I think one of the best steps is embracing minimalist design. By reducing unnecessary decorations and complex structures, we will discover effective packaging to be more concise and practical. In my experience, a simple design lowers material costs and processing difficulties and improves production efficiency. Another effective strategy is offering concentrated product options that require less packaging overall.

Let’s consider the impact of reducing packaging layers:

| Packaging Layers | Material Usage | Cost Savings | Environmental Impact |

|---|---|---|---|

| Multiple | High | Low | High |

| Single | Low | High | Low |

One of the companies I used to work with effectively reduced packaging by redesigning their boxes to perfectly fit the product, eliminating the need for void fillers. This also reduced shipping costs. Also, design packaging that can be reused. For example, a sturdy box could be repurposed for storage, further reducing waste and promoting sustainability.

Which type of packaging is most suitable for reducing packaging cost?

Searching for the most cost-effective packaging solution? There are many materials and designs out there therefore it is difficult to identify the right option.

For reducing packaging costs, flexible packaging like pouches and squeeze tubes is most suitable due to its lightweight nature and lower material usage. Recycled cardboard and kraft paper are also cost-effective and eco-friendly options.

I think it’s essential to assess your product’s needs and brand identity. Flexible packaging, such as pouches and squeeze tubes, costs effective packaging with reduced shipping costs. Choosing eco-friendly materials like kraft paper and recycled cardboard is not only budget-friendly but also resonate with eco-conscious consumers. I’ve found that aligning your packaging choices with sustainability trends can boost your brand image.

Here’s a breakdown of cost-effective packaging options:

| Packaging Type | Material | Cost | Benefits |

|---|---|---|---|

| Pouches | Plastic Film | Low to Moderat | Lightweight, flexible, good for liquids |

| Squeeze Tubes | Plastic | Moderate | Ideal for creams, lotions, and gels |

| Kraft Paper | Paper | Low | Eco-friendly, rustic look |

Don't forget modular packaging design and can pack various products using the same packaging material. This generates bulk purchasing savings and reduces the need for unique packaging for each product.

Does reducing the cost of a product's packaging lead to higher profits?

Wondering if cutting packaging costs really impacts your bottom line? It's a valid concern.

Reducing the cost of a product's packaging can lead to higher profits by freeing up resources that can be reinvested into other business areas. Optimizing packaging also improves operational efficiency and reduces waste.

I've found that effective packaging not only protects the product but also directly impacts profitability. Lower costs can be achieved through efficient manufacturing models and also translates to larger savings. When I worked with this cosmetic brand, they did some changes, and with this they reduced the cost while maintaining the product integrity, thus leading to a boost to customer satisfaction.

Let’s consider the impact of reduced packaging costs and profits:

| Strategy | Impact on Cost | Impact on Profit |

|---|---|---|

| Minimalist Design | Decrease | Increase |

| Sustainable Materials | Decrease | Increase |

| Optimized Size and Shape | Decrease | Increase |

By focusing on cost-effective and durable materials, while ensuring products arrive undamaged, you can achieve substantial savings in production processes. Ensure that the packaging aligns with brand reliability and trustworthiness.

Conclusion

In short, reducing cosmetic packaging costs while maintaining quality is achievable. It requires a strategic approach focusing on design, materials, and supply chain efficiency. By doing so, you can improve your profitability and commitment to sustainability.

Written by

Mike Lee

You may also be interested in:

How Can You Reduce Packaging Costs Without Compromising Sunscreen Bottle Quality?

You're trying to grow your sunscreen brand, but rising packaging costs are eating into your

The Complete Importing Guide for Spray Bottles: How Can You Simplify the Process?

You worry about complex customs paperwork and your spray bottles arriving damaged. This uncertainty can

From Molding to Assembly: How Does RLAND Ensure Consistent Spray Quality?

You receive a new shipment of spray bottles, but find that some leak and others

How Will Sustainable Packaging for Skincare Mists Change by 2026?

You know your brand needs to be more sustainable, but the options are overwhelming. You