How Do You Work Effectively with a Sunscreen Bottle Supplier from Design to Delivery?

November 18, 2025 • Mike Lee

You have a vision for your sunscreen brand, but turning that idea into a physical bottle seems like a complex journey. You're worried about miscommunications, costly mistakes, and a final product that doesn't match your dream.

To work effectively with a supplier, you must embrace a structured, collaborative partnership built on constant communication. This means deep involvement from the initial design discussion and rigorous sample approval to transparent oversight of mass production.

Your insight about communication being the key is something I see proven every single day. I once had a new client who was very nervous about sourcing from China. Their previous supplier was unresponsive, sending them a sample that was "close enough" and then delivering a final product with a different shade of white and a pump that clogged. They lost an entire season. With us, we started with a two-hour video call just to discuss the design. We sent them 3D printed models to feel the shape. We sent color chips for them to approve under different lights. They were part of the process, not just a customer waiting for an email. That close collaboration is how you guarantee the product you envisioned is the product that gets delivered.

How can your sunscreen bottle design strengthen your brand?

You might see your bottle as just a container for your formula. But on a crowded shelf, a generic bottle makes your brand invisible, lost in a sea of similar products.

Your bottle's design is your primary marketing tool. It communicates your brand's unique identity—be it clinical, natural, or luxurious—through its shape, color, and texture, creating an instant emotional connection with your ideal customer.

The initial design conversation is your first and most important test of a supplier. A great partner won't just ask for your drawing; they will ask about your brand, your customer, and your goals. They act as a consultant. This collaborative discussion is where you define the visual language of your product. A professional supplier will have the expertise to translate your brand identity into a physical object.

| Design Element | How It Communicates Your Brand |

|---|---|

| Shape & Form | A sleek, minimalist cylinder can feel clinical and scientific. A soft, rounded shape can feel gentle and natural. |

| Color Palette | Bright, vibrant colors scream fun and sun. Muted earth tones or clean whites suggest organic or dermatologist-recommended. |

| Material & Finish | A heavy, glossy finish feels premium and luxurious. A soft-touch matte finish feels modern and sophisticated. |

| Applicator Type | A fine-mist spray is about convenience and elegance. A traditional lotion pump is about control and reliability. |

By discussing these points in detail, you not only create a better product but also confirm that your supplier is a true partner.

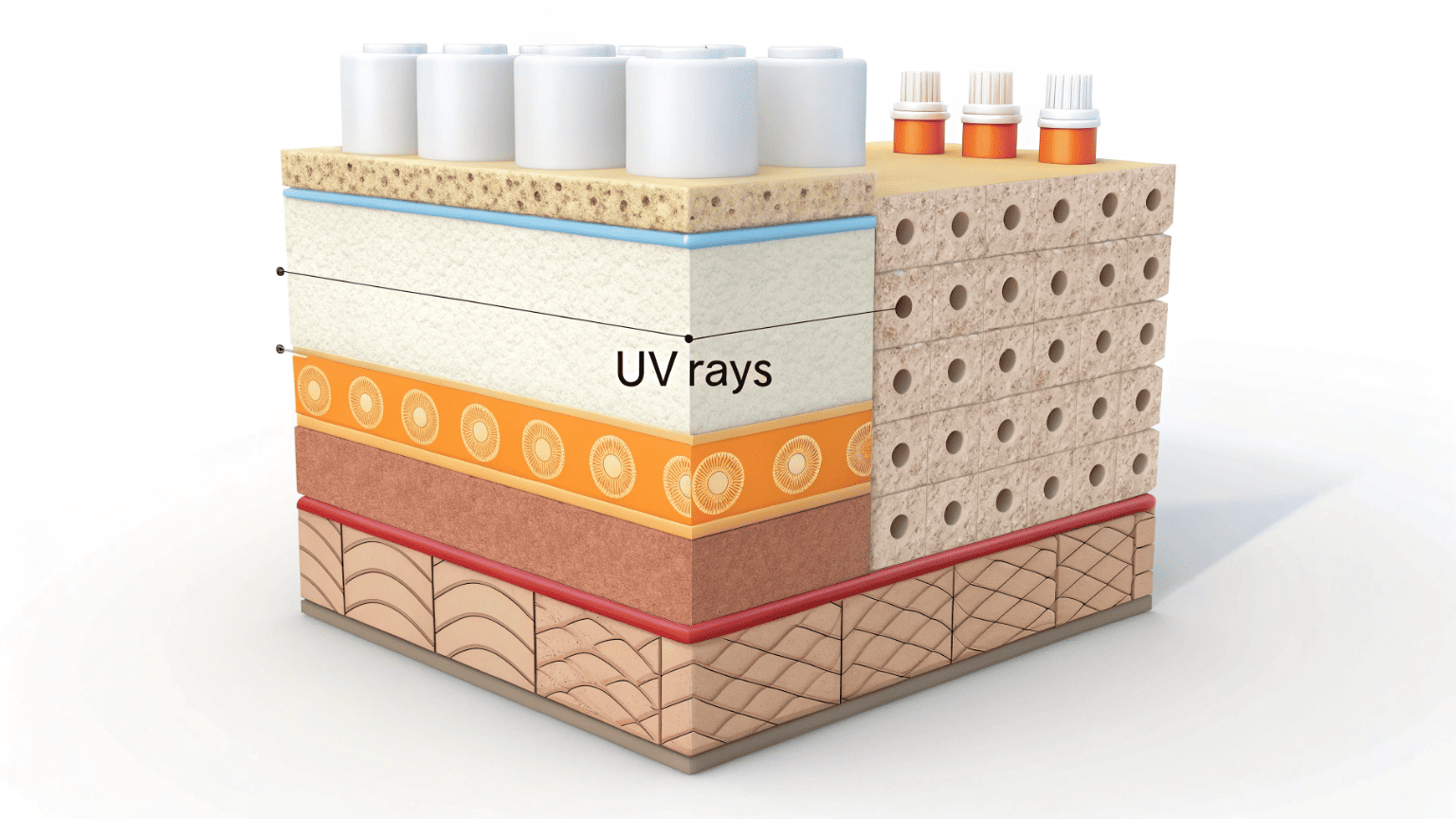

What materials should you prioritize for sunscreen bottles?

You're excited about the look of your bottle, but you overlook the technical details. However, the wrong material can allow UV light to degrade your expensive formula, rendering it ineffective.

You must prioritize UV-blocking materials like opaque HDPE or multi-layer PET to protect the formula's active ingredients. The material choice is a non-negotiable technical requirement that ensures product safety and efficacy.

This is another critical conversation where a reliable supplier's expertise shines. They should be able to explain the pros and cons of different materials not just for cost, but for performance. This is your chance to discuss the technical heart of your packaging.

Balancing Protection and User Experience

The goal is to find the perfect intersection of product protection, user feel, and cost. Your supplier should be able to provide samples of different materials so you can feel the difference yourself.

| Material Option | Key Benefit | Best For... |

|---|---|---|

| Opaque HDPE | Cost-effective, excellent chemical resistance, naturally UV-blocking when colored white. The industry standard for squeezable tubes and bottles. | Mid-market, family-focused, or high-volume products. |

| PET | Premium, glass-like appearance. Can be combined with UV additives to protect the formula while allowing for translucent colors. | High-end brands, facial sunscreens, or luxury lines. |

| Multi-Layer (Co-Ex) | The ultimate protection. An inner layer protects the formula while an outer layer can be decorated and provides UV defense. | Highly sensitive, organic, or preservative-free formulas. |

Insisting on samples to test is crucial. This step validates your supplier's claims and ensures the material meets your quality standards.

How do you manage the process from sample approval to final delivery?

You've approved a perfect sample and now feel your work is done. But the gap between a single perfect sample and 50,000 perfect units is where quality control and communication are most vital.

Manage this phase with proactive communication. Establish clear quality checkpoints, request production updates and photos, and confirm the shipping plan and documentation well before the production run is complete. Stay involved.

This is where the trust you've built pays off. A reliable supplier will welcome your involvement during production, seeing it as a way to ensure your satisfaction. An unreliable one will go silent. Your close cooperation during this phase is the ultimate guarantee of quality.

Key Stages of Production and Delivery Management:

- The "Golden Sample" Approval: Before mass production, you approve one final sample, the "golden sample." This exact bottle becomes the quality standard that every other unit will be compared against.

- Mass Production Updates: A good partner will be happy to send you photos or short videos of the production line running. They can show you the bottles coming off the injection molding machines or the printing process in action. This transparency is a huge sign of confidence and reliability.

- Final Quality Control (QC): Before the final payment, you can request a final QC report. Many brands hire a third-party inspection service in China to go to the factory and check a random sample of the finished goods against the golden sample.

- Logistics Confirmation: Confirm the shipping method (sea vs. air), the accuracy of all customs documents, and the final delivery timeline.

Conclusion

Working with a sunscreen bottle supplier is a partnership. Success comes from deep, continuous communication from the first design sketch to the final delivery, ensuring your vision is perfectly executed.

Written by

Mike Lee

You may also be interested in:

How Can You Reduce Packaging Costs Without Compromising Sunscreen Bottle Quality?

You're trying to grow your sunscreen brand, but rising packaging costs are eating into your

The Complete Importing Guide for Spray Bottles: How Can You Simplify the Process?

You worry about complex customs paperwork and your spray bottles arriving damaged. This uncertainty can

From Molding to Assembly: How Does RLAND Ensure Consistent Spray Quality?

You receive a new shipment of spray bottles, but find that some leak and others

Mist Pump vs. Trigger Spray vs. Mini Refill Sprayer: Which One Should You Choose?

You're developing a new spray product, but you're stuck on the packaging. You see mist