Why is Choosing the Right Sunscreen Bottle Material So Critical?

November 19, 2025 • Mike Lee

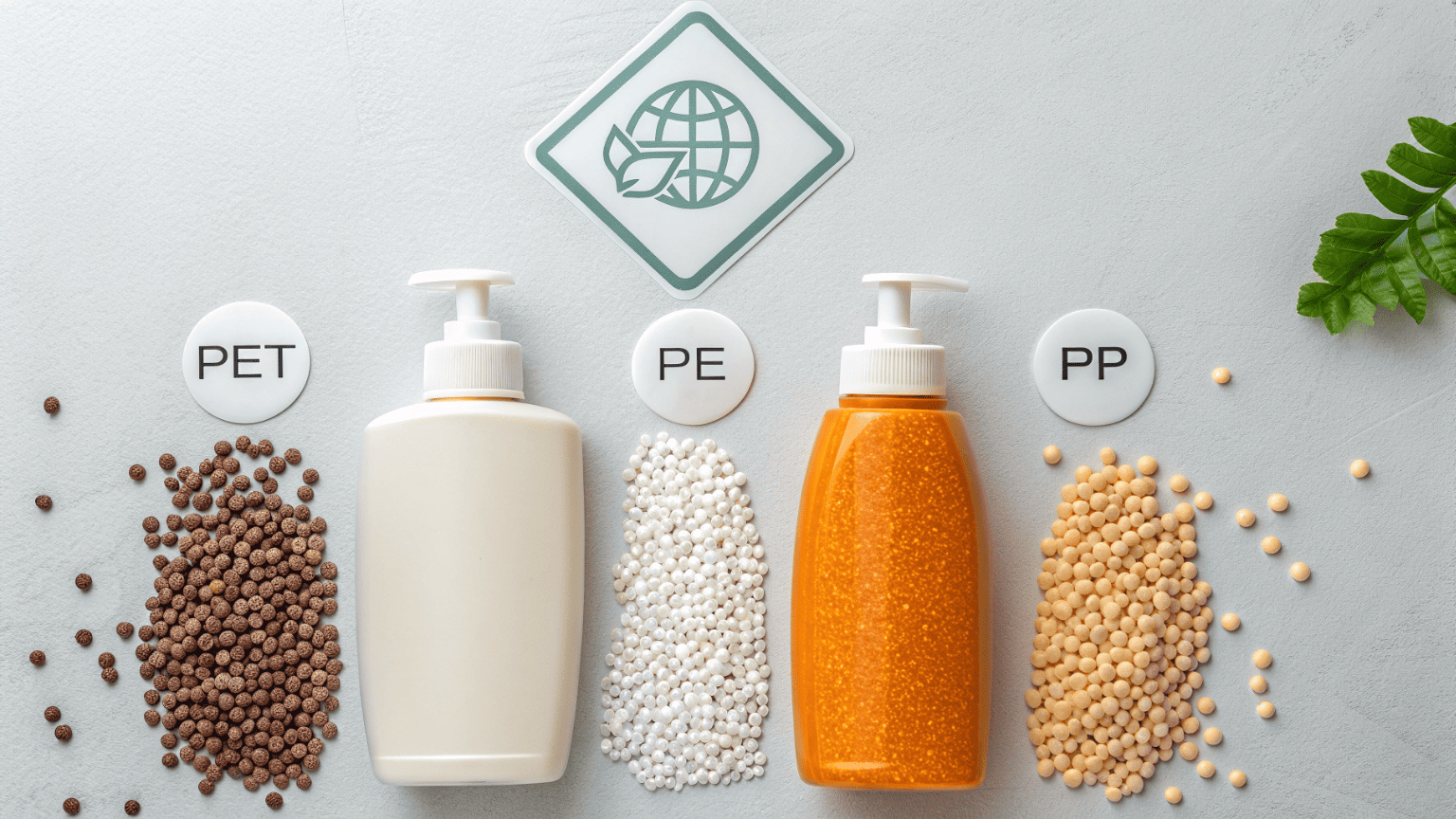

You've perfected your sunscreen formula, but now you need to package it. You see options like PET, PE, and PP, but they just look like different types of plastic, leaving you unsure of how to choose.

Choosing the right material is critical because it directly impacts your sunscreen's stability, safety, and effectiveness. The bottle must protect sensitive ingredients from UV light and air while being chemically compatible with the formula to preserve its SPF and PA ratings.

Your insight about each material having pros and cons is the key. I remember a startup brand that came to us after a failed launch. They had chosen a beautiful, clear PET bottle for their all-natural sunscreen because it looked premium. But they didn't account for the plastic's compatibility with the essential oils in their formula. Over a few weeks, the oils caused the plastic to become cloudy and slightly warped. Worse, the formula's stability was compromised. We switched them to an opaque, multi-layer PE bottle specifically designed for chemical resistance. It wasn't as transparent, but it guaranteed the product's integrity. It's a tough lesson: the material isn't just about looks; it's about science.

How do FDA sunscreen guidelines influence your bottle choice?

You know the FDA has strict rules for sunscreen formulas and SPF claims. But you might overlook how those rules indirectly dictate the type of packaging you must use to be compliant.

FDA guidelines require your sunscreen to maintain its stated SPF and stability throughout its shelf life. Therefore, your bottle material must be proven through stability testing to not react with the formula or allow it to degrade.

The FDA doesn't pre-approve packaging, but it holds you responsible for the final product's safety and efficacy. This means your packaging choice is a critical part of your compliance strategy. A reliable supplier understands this and can guide you on materials that have a long history of passing stability tests with common sunscreen actives.

| FDA Guideline Area | Impact on Bottle Material Choice |

|---|---|

| SPF & Broad Spectrum Claims | The formula's active ingredients that provide this protection are sensitive to light and air. Your bottle must use UV-blocking materials (e.g., opaque colored PE/PP) to ensure the SPF value doesn't drop over time. |

| Product Stability | The FDA requires stability testing. The chosen plastic (PET, PE, PP) must be chemically inert and not "leach" components into the formula or cause the emulsion to separate. This is a crucial compatibility test. |

| Material Safety | The plastic resin used must be safe for contact with cosmetics. Suppliers must use high-quality, cosmetic-grade polymers that are free from harmful contaminants like heavy metals. |

How does the UVA rating (PA+++ / PPD) affect your bottle material?

You proudly advertise your high PA++++ UVA rating on your box. But if sunlight can penetrate your bottle, it can destroy the very UVA filters that provide that protection, making your claim invalid.

A high PA or PPD rating relies on specific UVA-filtering ingredients. These ingredients are often highly sensitive to UV degradation, so your bottle material must be opaque or contain UV blockers to act as a shield and preserve that protection.

Understanding these ratings helps you see why your bottle is so much more than a container. It's the first line of defense for your formula's efficacy.

What are PA and PPD?

- PPD (Persistent Pigment Darkening): This is the method used to measure protection against UVA rays—the rays that cause aging and deep skin damage. A higher PPD score means better UVA protection.

- PA Rating System: Developed in Japan, this system simplifies the PPD score into levels. It's widely used in Asian and many global markets.

- PA+ = PPD of 2 to 4

- PA++ = PPD of 4 to 8

- PA+++ = PPD of 8 to 16

- PA++++ = PPD of 16 or higher

When you select a material like opaque HDPE or a PET bottle with UV-blocking additives, you are building a physical barrier to protect the fragile chemistry that delivers that high PA++++ rating. Your material choice ensures the promise on the label is the reality in the bottle.

How do you choose between PET, PE, and PP for your sunscreen?

You're faced with a choice of different plastics, and each seems to have its own benefits. You need a clear way to decide which one is right for your specific product and brand identity.

The choice depends on your priorities: choose PET for a premium, rigid, glass-like look; choose PE for its excellent flexibility and squeezability; and choose PP for its superior heat resistance and compatibility with airless pump systems.

This is the core decision you'll make with your packaging supplier. A good supplier will walk you through the pros and cons of each, but here is a quick guide to get you started. Each material serves a different purpose.

| Material | Pros | Cons | Best For... |

|---|---|---|---|

| PET | Excellent clarity, glass-like appearance, good chemical barrier. | Less squeezable, can be more brittle than PE. | Premium lotion pumps, sprays, and bottles where a rigid, high-end feel is desired. |

| PE (HDPE/LDPE) | Very durable, cost-effective, excellent for squeezable tubes and bottles. | Can have a less premium feel than PET, less transparent. | Classic sunscreen tubes, family-size bottles, and products where squeezability is key. |

| PP | High heat resistance, very rigid, excellent chemical resistance. Perfect for lids and airless systems. | Can be brittle at cold temperatures, lower transparency. | Airless pump bottles, caps, closures, and jars that require high stiffness and heat tolerance. |

Conclusion

Choosing your sunscreen bottle material is a scientific decision, not just an aesthetic one. By matching the right plastic—PET, PE, or PP—to your formula, you protect its efficacy and ensure your brand's promise is delivered.

Written by

Mike Lee

You may also be interested in:

Which Cap is Right for Your Spray Bottle: Overcap, Clip Lock, or Screw Cap?

You've spent months perfecting your formula and choosing the right spray pump. Now you need

Pump Doesn’t Work After 1–3 Months? The Real Reasons Spray Bottles Fail Over Time

You’ve launched a fantastic product with a fine mist sprayer, but after a few months,

Why Are Sunscreen Formulas So Tough on Packaging?

You've developed a brilliant sunscreen formula, but the packaging keeps failing. Bottles are turning yellow,

What Are the Best Sustainable Packaging Solutions for Sunscreen Brands?

You want to use sustainable packaging, but you're afraid it will fail. Choosing the wrong