Why Do Barrier Properties in Cosmetic Containers Matter to Your Brand?

October 22, 2025 • Mike Lee

You've spent a fortune developing a perfect formula with powerful active ingredients. But if your packaging fails, that formula can spoil on the shelf, destroying your product's effectiveness and your customer's trust.

Barrier properties refer to a container's ability to protect its contents from external elements like oxygen, UV light, and moisture. Choosing the right barrier packaging is crucial for preserving your formula's stability, potency, and shelf life.

Your insight about active ingredients is a conversation I have with brands almost every week. I remember a passionate startup founder who came to us with a brilliant Vitamin C serum. She was determined to use a crystal-clear bottle to show off the product's beautiful, light color. We had to have a frank discussion. We explained that her star ingredient, ascorbic acid, is highly sensitive to UV light. In a clear bottle, her potent serum would become useless in a matter of weeks sitting on a shelf. It was a tough realization, but we guided her to a beautiful opaque white bottle with a UV-resistant coating. It protected her formula and ultimately, her brand.

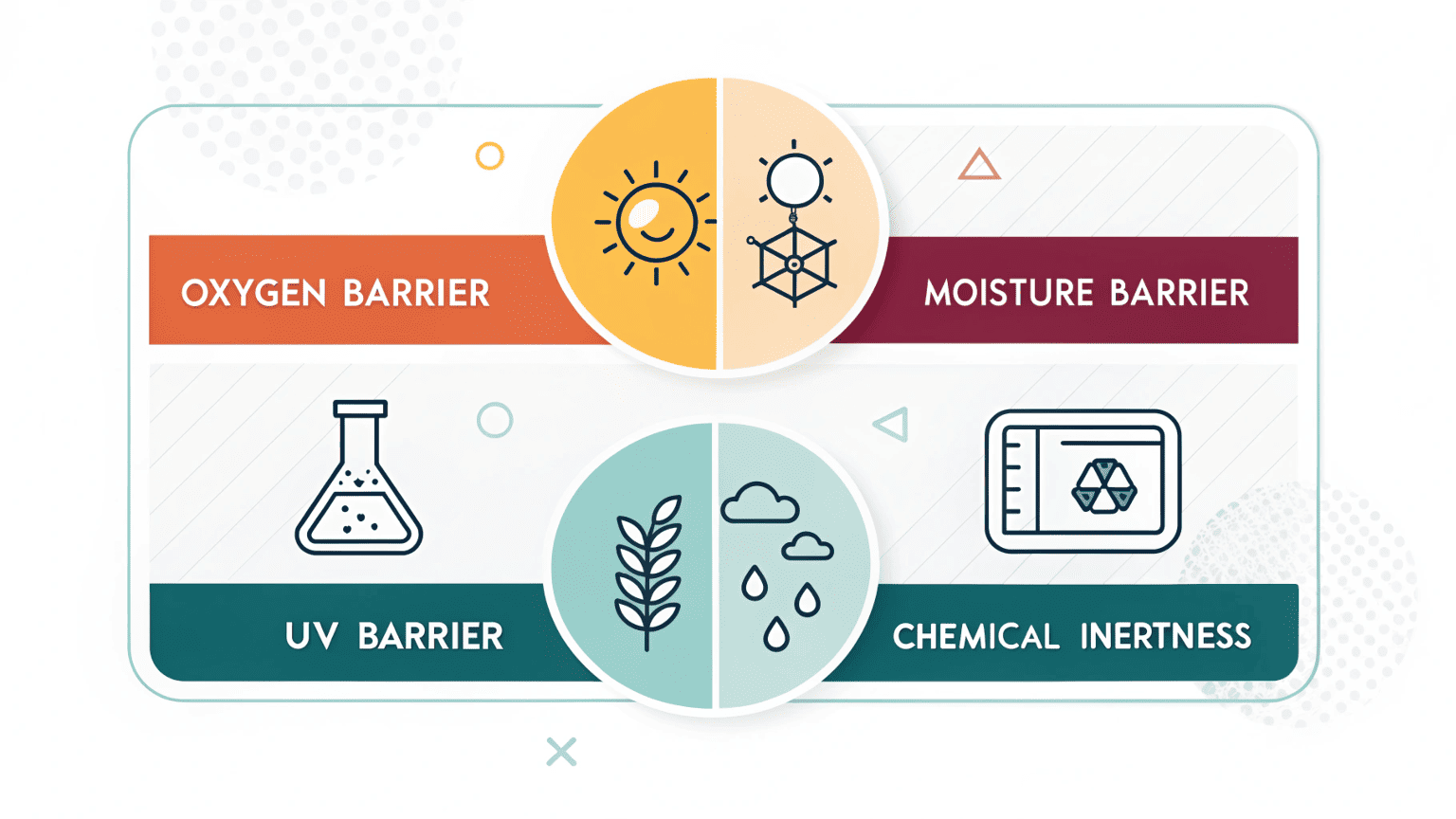

What Are the Essential Properties of Barrier Packaging?

You hear suppliers talk about "good barrier properties," but the term feels vague. You're not sure what specific qualities you should be asking about to truly protect your product.

The essential properties are a material's ability to block four things: oxygen, moisture, UV light, and chemical interaction. Each property prevents a different type of degradation, from color change to loss of potency.

Understanding these four key properties allows you to have a much more specific and productive conversation with your packaging partner. It turns a vague concept into a concrete checklist for safeguarding your formula.

| Barrier Property | What It Protects Against | Why It Matters for Your Product |

|---|---|---|

| Oxygen Barrier | Oxidation | Prevents oils and lipids from going rancid (bad smells), stops color changes in dyes, and protects oxygen-sensitive actives like Retinol. |

| Moisture Barrier (MVTR) | Moisture Gain or Loss | Stops a rich cream from drying out and hardening. Prevents a dry powder or bath salt from absorbing air moisture and clumping together. |

| UV Light Barrier | Photodegradation | Protects light-sensitive vitamins (like A and C), essential oils, and natural colorants from breaking down and losing their effectiveness. This is why opaque or dark-colored packaging is so important. |

| Chemical Inertness | Leaching & Absorption | Ensures the plastic container doesn't leach unwanted chemicals into your formula. It also prevents the product's ingredients (like strong fragrances or solvents) from being absorbed into the plastic wall, which would alter the formula. |

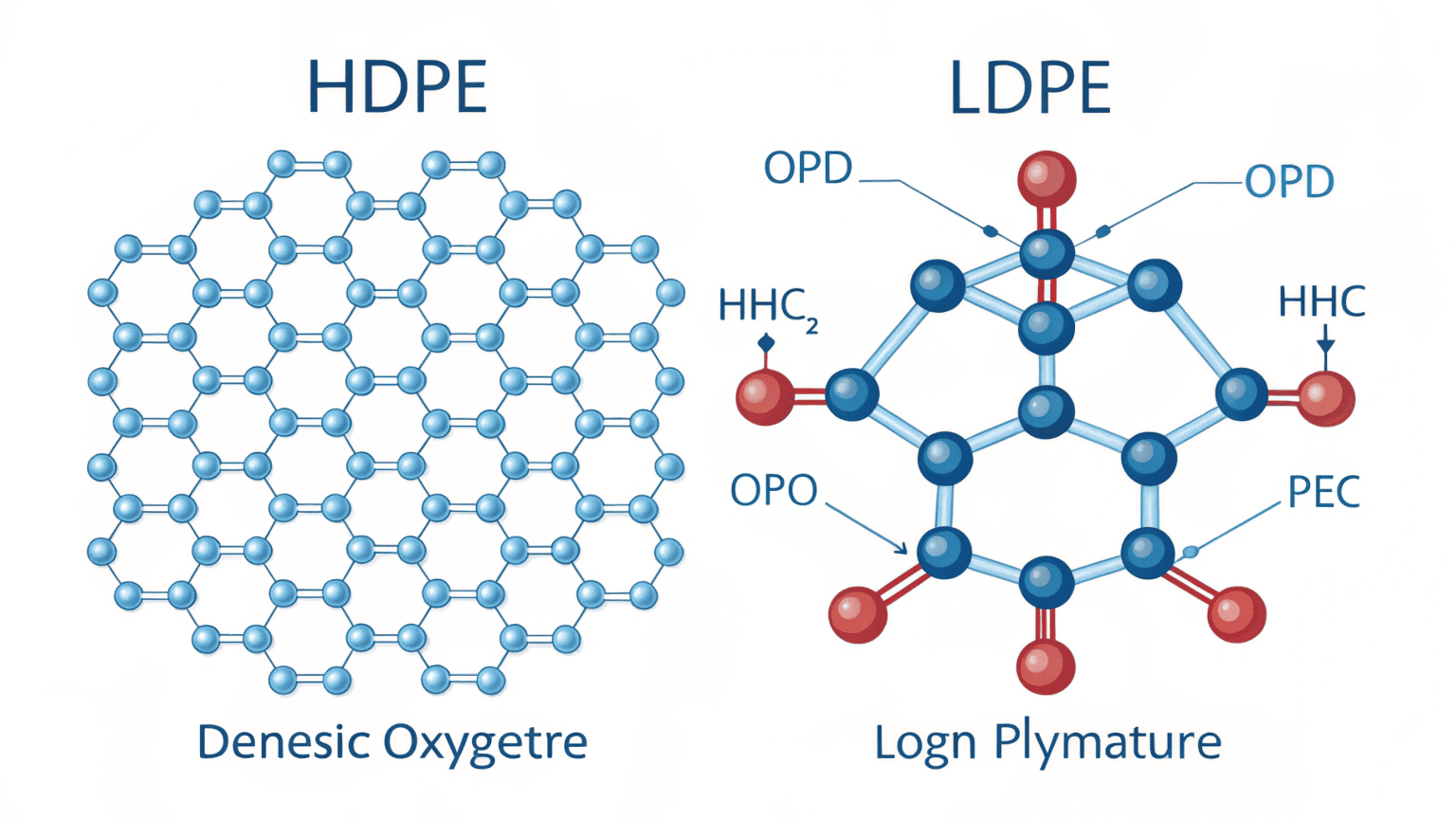

What is the theory behind how barrier properties work?

You know what barrier properties do, but you're unclear on the science. How can one piece of plastic be a strong barrier while another one is weak?

The theory is based on a material's molecular structure. Densely packed and tightly bonded molecules create a difficult, maze-like path for outside elements like oxygen or water vapor to pass through, resulting in better barrier performance.

It’s helpful to think of a plastic wall not as a solid shield, but as a very dense forest. The goal is to make that forest as difficult as possible for anything to get through. This process is called permeation, and several factors determine how slow it is.

Factors Influencing Barrier Performance

- Density and Crystallinity: Plastics with a more orderly, crystalline molecular structure are denser and have fewer gaps. This is why High-Density Polyethylene (HDPE) is a much better moisture barrier than Low-Density Polyethylene (LDPE).

- Material Choice: Different plastic families have inherent strengths. For example, Polyethylene (PE) is an excellent moisture barrier, while Ethylene Vinyl Alcohol (EVOH) is an exceptional oxygen barrier.

- Wall Thickness: A thicker wall creates a longer path for molecules to travel, which generally improves barrier performance across the board.

Advanced Solution: Multi-Layer Technology

For products that need the ultimate protection from both oxygen and moisture, we use advanced co-extrusion technology. We manufacture a single bottle wall with multiple, fused layers.

- Inner Layer (e.g., PP): Chemically resistant to protect the formula.

- Middle Layer (e.g., EVOH): An ultra-thin, super-high-performance oxygen barrier.

- Outer Layer (e.g., PP): Provides structural strength, a premium feel, and a printable surface.

This approach gives you the best of all worlds without compromising on aesthetics or function.

What does the "barrier properties of plastic" specifically refer to?

You're looking at spec sheets for different plastics like PET, PP, and HDPE. You see ratings for barrier properties, but you want to know what they mean in a practical sense for your product.

It refers to a specific plastic type's inherent ability to resist the permeation of gases, liquids, and light. No single plastic is perfect at everything, so you must match the plastic's strengths to your formula's needs.

Let's break down the most common plastics we use and what their barrier properties mean for you. Choosing the right one is one of the most important decisions you'll make for your product's long-term success.

A Practical Guide to Plastic Barriers

-

PET (Polyethylene Terephthalate):

- Strengths: Excellent oxygen barrier and good chemical resistance. This makes it perfect for products with sensitive oils or actives that can oxidize. Its clarity is a big selling point, which can be protected with UV coatings or colorants.

- Common Uses: Jars, lotion bottles, beverage containers.

-

PP (Polypropylene):

- Strengths: Excellent moisture barrier and great chemical resistance, especially to acids and alcohols. It also has a very high melting point, making it suitable for hot-fill products.

- Weakness: It is a poor oxygen barrier.

- Common Uses: Airless pump bottles, jars, and caps. Ideal for thick creams that need protection from drying out.

-

HDPE (High-Density Polyethylene):

- Strengths: The best moisture barrier among common plastics. It is also very robust and impact-resistant.

- Weakness: It is also a poor oxygen barrier.

- Common Uses: Shampoo and conditioner bottles, body wash containers. It is the go-to material for products where preventing water loss is the number one priority.

By understanding this, you can see why a Vitamin C serum (needs oxygen/UV barrier) might go in a UV-coated PET bottle, while a thick body butter (needs moisture barrier) is perfect for a PP or HDPE jar.

Conclusion

Barrier properties are the unseen guardian of your formula. Matching your product's needs with the right material's strengths is the key to ensuring customer satisfaction and preserving the quality you worked so hard to create.

Written by

Mike Lee

You may also be interested in:

Why Are 50ml Spray Bottles the Best-Selling Size?

You're developing a new product and you're stuck on a critical decision: the bottle size.

Which Cap is Right for Your Spray Bottle: Overcap, Clip Lock, or Screw Cap?

You've spent months perfecting your formula and choosing the right spray pump. Now you need

Pump Doesn’t Work After 1–3 Months? The Real Reasons Spray Bottles Fail Over Time

You’ve launched a fantastic product with a fine mist sprayer, but after a few months,

Why Are Sunscreen Formulas So Tough on Packaging?

You've developed a brilliant sunscreen formula, but the packaging keeps failing. Bottles are turning yellow,