The Complete Importing Guide for Spray Bottles: How Can You Simplify the Process?

January 4, 2026 • Mike Lee

You worry about complex customs paperwork and your spray bottles arriving damaged. This uncertainty can delay your product launch and hurt your budget, making you hesitant to import from overseas.

Simplify importing by working with an experienced partner who understands HS codes, certifications, and proper packaging. For spray bottles, this means using protective foam for nozzles and ensuring the correct material certifications are ready for customs.

I remember a new client, a cosmetics brand, who was terrified of their first international order. They had nightmares about their shipment being stuck at the port for weeks. I walked them through the process step-by-step, showing them that spray bottles are considered general goods, which makes customs much simpler than they imagined. We prepared all the documents in advance and showed them photos of how we packed the spray heads in special foam. Their shipment cleared customs in two days. That experience showed me how important it is for us to be not just a manufacturer, but an expert guide in logistics.

What is the HS code for a spray bottle?

You're trying to calculate import duties, but you're lost in a sea of confusing codes. Using the wrong code could lead to costly fines or your shipment being held indefinitely by customs.

The most common HS code for plastic spray bottles is 3923.30, which covers "Carboys, bottles, flasks and similar articles" of plastics. However, always confirm with your customs broker, as slight variations can exist.

The Harmonized System (HS) code is a universal language for classifying goods for customs. Getting it right is crucial for a smooth import process. For the products we make, like plastic spray bottles, the code usually falls under Chapter 39 of the customs tariff, which is for plastics and articles thereof. The specific code is typically 3923.30. This classification identifies the product as a plastic bottle or similar container. Why is this so important? This code tells your country's customs authority what the product is, which then determines the import duty (tax) you need to pay. As your manufacturing partner, we always include the correct HS code on all commercial invoices and shipping documents. This prevents confusion at the port and ensures you are charged the correct tax rate, avoiding any surprise fees or delays. It's a small detail that makes a big difference.

How should spray bottles be packed for shipment?

You imagine boxes being thrown around during transit. You worry that your beautifully made spray bottles will arrive scratched, crushed, or with broken nozzles, making a large part of your order unusable.

We pack spray bottles by separating the bottles and spray heads. Bottles are layered with protective dividers, while spray heads are secured in custom anti-vibration foam to prevent any damage to the delicate pump mechanism during shipping.

Proper packaging is a science, and it's something we take very seriously. Your insight is spot on: the spray head is the most vulnerable part. A standard box is not enough. Our method protects every component of your order.

| Packaging Component | Our Method | Why It's Critical |

|---|---|---|

| Bottle Bodies | Stacked in strong, double-walled cartons with cardboard or plastic dividers between each layer. | Prevents bottles from rubbing against each other, which causes scuffs and scratches. It also adds structural integrity to the box. |

| Spray Heads | Placed individually into custom-cut, high-density foam inserts. This foam is anti-vibration and shock-absorbent. | Protects the delicate internal pump mechanism and tube from being bent or broken. This is the single most important step for ensuring function. |

| Outer Protection | Boxes are sealed and clearly labeled. We ensure they are not exposed to direct sunlight or excessive heat in our warehouse before shipping. | Protects the plastic from potential warping and maintains the integrity of the product before it even begins its journey. |

This multi-part system ensures that the products arrive at your facility in the same perfect condition they were in when they left our factory.

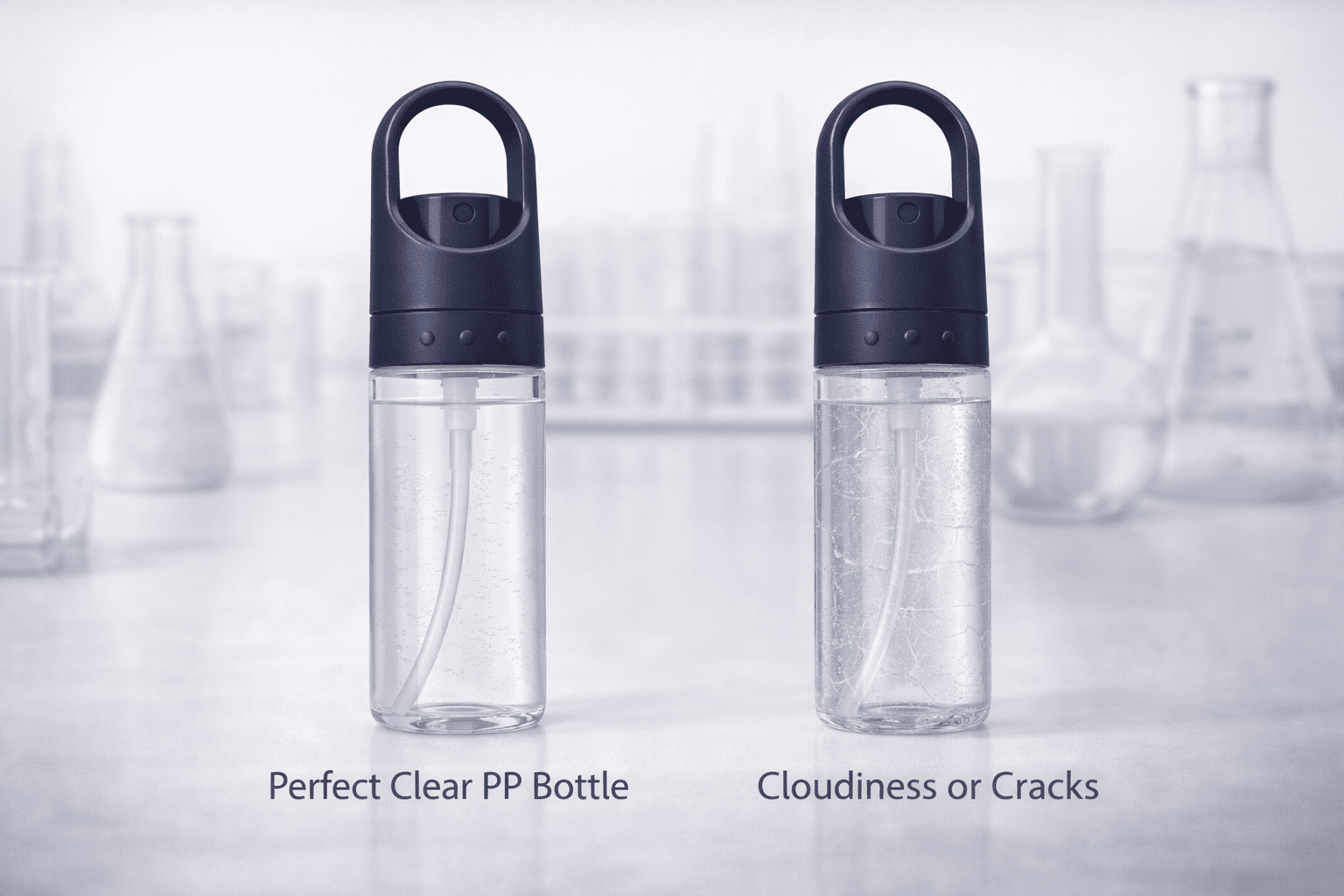

When transferring sanitizer, what material is best?

You want to offer a refillable sanitizer bottle, but you've heard that alcohol can damage certain plastics. Choosing the wrong material could cause the bottle to degrade, leading to leaks and customer complaints.

When bottling sanitizers with high alcohol content, you must use a chemically resistant plastic like PP (Polypropylene) or PET. Avoid plastics that can become brittle or break down when exposed to alcohol.

This is a critical technical question that directly impacts product safety and performance. Your choice of plastic must be compatible with your formula. This is especially true for hand sanitizers, which often contain 60-80% alcohol. Alcohol is a solvent and can be aggressive toward certain plastics. If you're planning to market a spray bottle for sanitizer, you need the right material. Polypropylene (PP) is an excellent choice. It has very high chemical resistance and is not affected by alcohol, making it a safe and reliable option. PET is another common and effective material for alcohol-based products. As your manufacturing partner, this is one of the first questions we ask. By understanding your product's formula, we can guide you to the correct material, providing the necessary documentation (like our SGS reports) to prove its suitability and safety. This protects your product, your brand, and your customers.

Conclusion

Importing spray bottles is straightforward when you have a partner who manages the details. We handle the codes, certifications, and expert packaging so you can focus on building your brand with confidence.

Written by

Mike Lee

You may also be interested in:

How Can You Reduce Packaging Costs Without Compromising Sunscreen Bottle Quality?

You're trying to grow your sunscreen brand, but rising packaging costs are eating into your

From Molding to Assembly: How Does RLAND Ensure Consistent Spray Quality?

You receive a new shipment of spray bottles, but find that some leak and others

Mist Pump vs. Trigger Spray vs. Mini Refill Sprayer: Which One Should You Choose?

You're developing a new spray product, but you're stuck on the packaging. You see mist

How Can You Choose a Reliable Spray Bottle Manufacturer in China?

You need to source spray bottles from China to stay competitive, but you're terrified. You