Key Questions to Ask Before Ordering Custom Packaging?

September 2, 2025 • Mike Lee

Ready to create amazing custom packaging? It's exciting, but diving in without a plan can lead to costly errors, delays, and a product that misses the mark.

Before ordering, ask your supplier about customization limits, mold options, material choices, printing techniques, prototyping processes, and quality control. These questions ensure their capabilities match your product's positioning and brand vision.

I’ve guided countless brands through this process, from startups to established names like RAS BEAUTY. The most successful projects always begin with asking the right questions. It’s what separates a smooth launch from a stressful scramble. Let's walk through the exact questions you need to ask to find the right partner.

How customizable is your packaging?

You have a unique brand vision, but you're worried a supplier will force you into a standard template. True customization feels out of reach or too expensive.

Assess customization by asking about their ability to create new molds, their range of available materials and colors, the finishing techniques they offer, and their Minimum Order Quantities (MOQs) for truly custom projects.

"Customizable" can mean different things to different suppliers. For some, it's just adding a logo to a stock bottle. For us at Rland, it means building from the ground up. Here’s how you can dig deeper to find out what a supplier can really do.

Mold Customization: New vs. Existing

Ask: “Can you create a completely new mold from my design, or can I only choose from your existing catalog?” Creating a new mold offers total freedom but costs more and takes longer. Modifying an existing mold is a good middle ground. We have a portfolio of over 1,000 references, which is a great starting point for many. But for brands with a unique vision, we use our in-house mold design team and 3D printers to create something entirely new.

Material & Color Matching

Ask: “What materials can you work with, and can you match specific Pantone colors?” Your product positioning dictates this. A luxury serum might need glass, while a body wash works well in PETG. We work with PE, PET, PP, PETG, and even hybrid materials. Then, for color, don't just accept "blue." Provide a Pantone code. We use a color-matching system to ensure every bottle in a product series, like for RAS BEAUTY, is perfectly consistent.

Surface Finishing & Printing

Ask: “What printing and finishing options do you offer?” This is how your brand's personality comes to life. A simple logo is one thing, but what about a metallic-gold hot stamp or a full-wrap gradient effect? We offer advanced processes like vacuum plating and UV spray to create a premium feel.

| Finishing Technique | Best For | What it Communicates |

|---|---|---|

| Hot Stamping | Logos, Borders | Luxury, Elegance |

| Silk Printing | Bold Graphics, Text | Clean, Modern |

| UV Spray | Full Coverage, Textures | Premium, Protective, Tactile |

| Gradient Color | Bottles, Jars | Trendy, Playful |

How do you create your packaging design?

You have a great idea on paper, but turning a sketch into a physical product that works is a huge challenge. The process seems complicated and full of technical hurdles.

To create your packaging design, start with a detailed design brief. Then, ask the supplier for 3D renderings and physical prototypes. Confirm their prototyping process, especially if they use 3D printing for fast turnaround.

This is where your vision meets reality. A great supplier acts as a partner to bridge that gap. Based on my experience, a successful design process isn't about just one thing; it's a series of clear, defined steps. This is how we ensure there are no surprises.

Start with a Clear Product Position

Before we talk about design, I first ask clients: "Who is this product for?" The design must serve your product's positioning. A premium Indian cosmetic brand will have different needs than an eco-friendly Indonesian homecare brand. A clear brief should include your target audience, brand values, key ingredients, and price point. This brief becomes our guide for every decision that follows.

The Prototyping Journey

Once we understand the vision, we bring it to life. Ask: “What is your prototyping process and timeline?” Waiting weeks for a sample kills momentum. This is why we invested in 10 industrial-grade 3D printers. For our clients, this means we can go from a 3D file to a physical sample in their hands in as little as 72 hours. This lets you feel the shape, test the cap function, and approve the design fast.

From Digital File to Physical Product

Ask: “What file formats do you need for a design?” A professional supplier should be able to work with standard 3D files like .STEP or .IGS. They should then provide you with detailed technical drawings that show every dimension, material, and weight before any expensive molds are cut. This approval stage is critical to getting exactly what you want.

What to Ask Before Choosing a Custom Packaging Supplier?

You found a supplier online with a low price, but you're worried. You've heard stories about poor quality, missed deadlines, and communication barriers that turn a dream project into a nightmare.

Before choosing a supplier, vet their reliability. Ask about their quality management certifications (like ISO 9001), their monthly production capacity, their project management process, and if they have a bilingual team to support communication.

This is the most important step. Finding a cheap supplier is easy. Finding a reliable partner that will grow with you is hard. Your product's positioning should guide your search. If you are a high-volume brand, you need a supplier built for scale. If you are a high-compliance brand, you need a supplier with robust quality systems. Here are the core areas to investigate:

Quality and Compliance Systems

Ask: "Are you ISO certified? Can you provide material traceability reports?" An ISO 9001 certification is not just a piece of paper; it means they have a documented, repeatable process for quality control. For a client like PT. PASCAL in Indonesia, which has strict regulatory needs, we provide full material traceability reports. This ensures their packaging meets all local compliance requirements, a service not all suppliers can offer.

Production Capacity and Scalability

Ask: “What is your monthly production capacity? What machinery do you have?” You need to know if they can handle your launch order and your growth. A small workshop with two machines cannot support a brand that plans to scale. We openly share that we have over 20 injection molding machines and can produce over 1 million units per month. This gives our clients confidence that we can meet their demand.

Communication and Project Management

Ask: “Who will be my main point of contact? Do they speak my language?” Bad communication is the number one reason projects fail. Delays, misunderstandings, and mistakes all stem from it. We addressed this by building a dedicated export department with bilingual project managers. A client like Shubihika from India has a dedicated account manager who fluently speaks English, ensuring nothing is lost in translation.

Conclusion

Choosing a custom packaging partner is a major decision. Asking these key questions about customization, design, and supplier reliability helps you find a true partner, not just a vendor, ensuring your vision becomes a successful reality.

Written by

Mike Lee

You may also be interested in:

How Can You Reduce Packaging Costs Without Compromising Sunscreen Bottle Quality?

You're trying to grow your sunscreen brand, but rising packaging costs are eating into your

The Complete Importing Guide for Spray Bottles: How Can You Simplify the Process?

You worry about complex customs paperwork and your spray bottles arriving damaged. This uncertainty can

From Molding to Assembly: How Does RLAND Ensure Consistent Spray Quality?

You receive a new shipment of spray bottles, but find that some leak and others

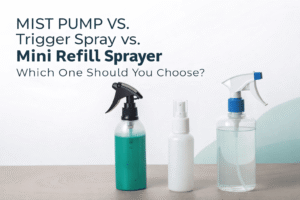

Mist Pump vs. Trigger Spray vs. Mini Refill Sprayer: Which One Should You Choose?

You're developing a new spray product, but you're stuck on the packaging. You see mist