How Should Your Brand Approach Minimum Order Quantities (MOQ)?

October 16, 2025 • Mike Lee

You have a fantastic product ready to go, but you keep hitting a wall with suppliers demanding huge minimum orders. You feel stuck, unable to launch affordably or scale effectively without a massive upfront investment.

The best approach to MOQ is strategic. Large brands leverage high volumes for cost-efficiency and deep customization, while small brands should focus on low-MOQ stock items to launch quickly and test the market with minimal risk.

Your insight about small brands using existing packaging and customizing it themselves is a strategy I recommend all the time. I remember a new indie skincare founder who came to us. She had a brilliant formula but a tiny budget. Instead of pushing for a 10,000-unit custom run, we provided her with 500 of our premium, in-stock frosted glass bottles. She designed beautiful, waterproof labels and launched her brand online. Six months later, she came back and placed an order for 15,000 units with custom color and printing. She used the low-MOQ option as a stepping stone, and it worked perfectly.

What Exactly Is an MOQ in the Cosmetics Industry?

You see the acronym "MOQ" everywhere, but it just feels like an arbitrary number designed to block small businesses. You're frustrated because you don't understand why you can't just order 100 or 500 custom bottles.

MOQ stands for Minimum Order Quantity. It's the smallest number of units a manufacturer can produce in a single run without losing money. For custom cosmetic packaging, this is often around 10,000 pieces.

The MOQ isn't an arbitrary rule; it's a fundamental reality of modern manufacturing. Understanding the "why" behind it can help you strategize more effectively.

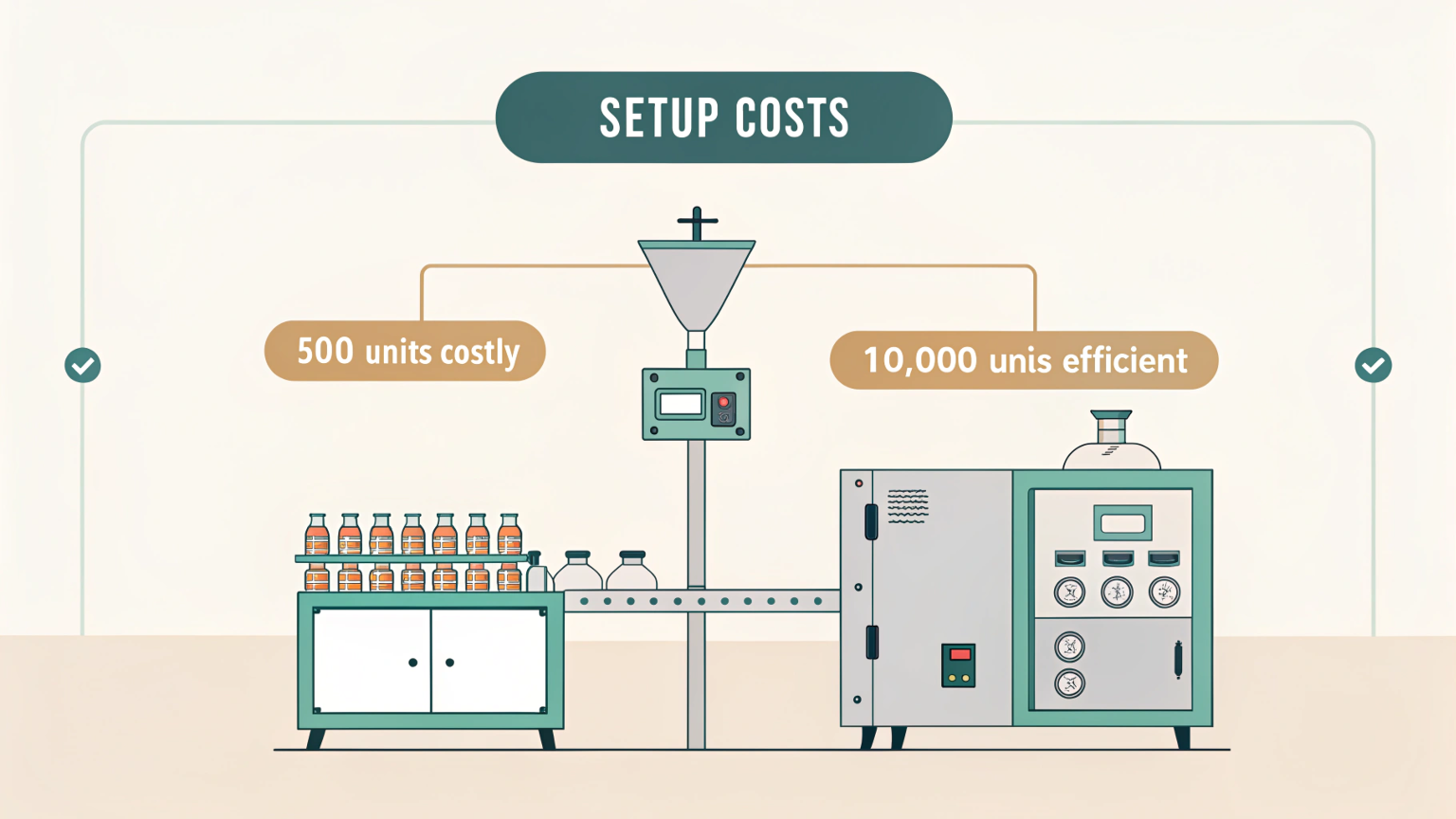

The Economics of a Production Run

Every time we start a production run for a custom order, we have to perform a series of costly and time-consuming steps:

- Machine Setup: A high-precision injection molding or blow molding machine must be stopped, cleaned, and fitted with the correct mold. This can take hours.

- Color Matching: If you want a custom Pantone color, our technicians have to mix raw colorants into the base plastic (like PP or PET) and run test batches until the color is a perfect match. This uses material and skilled labor.

- Material Purge: After the run, the machine must be purged of all the custom-colored plastic to prepare it for the next job.

These fixed setup costs are the same whether we produce 500 bottles or 10,000. Spreading that cost over a larger number of units is the only way to make the price per bottle viable for both you and us.

What's Included in a Typical MOQ

As you pointed out, hitting the MOQ threshold is what unlocks customization. A standard 10,000-unit order with us typically includes:

- Custom Pantone Color: We can match the plastic to your exact brand color.

- Basic Printing: A one- or two-color silk screen print of your logo and text is usually included.

What Is the Right MOQ Strategy for Your Brand's Size?

You know what MOQ is, but you're unsure how to build a purchasing strategy around it. You're torn between the desire for custom packaging and the financial reality of your business.

The right MOQ strategy must align with your brand's scale. Large, established brands focus on economies of scale, while small or new brands must prioritize flexibility and capital preservation.

The "best" strategy is completely different for a multinational corporation versus a startup launching its first product.

MOQ Strategy for Large Brands

As you noted, large brands like our partners at RAS BEAUTY aren't limited by a 10,000-unit MOQ; their orders are often in the hundreds of thousands. For them, the strategy is about leveraging this volume to its fullest potential.

| Strategic Goal | Action |

|---|---|

| Maximize Cost Savings | Placing orders for 100,000+ units drastically reduces the "per-unit" cost of both the product and shipping. |

| Deep Customization | High volume justifies investment in exclusive private molds, complex multi-color printing, and advanced surface treatments like vacuum plating or gradient sprays. |

| Supply Chain Security | Large, scheduled orders allow us to dedicate production lines, ensuring a stable and predictable supply of their unique packaging without interruption. |

MOQ Strategy for Small & Emerging Brands

For a small brand, tying up cash in 10,000 units of a single product is often a mistake. The strategy here is about being smart and agile.

- Use Stock Items: Choose a high-quality bottle or jar from our extensive catalog of existing molds. This eliminates the need for a custom run, and MOQs can be as low as 500-1,000 units.

- Customize Externally: Your insight about "DIY" is key. Invest your budget in high-quality, professionally printed labels or boxes that you can apply to the stock containers. This gives you a premium look without the high MOQ.

- Test and Iterate: Launch with a smaller batch. See what sells. You can always place a large custom order later once you have proof of concept and strong sales data.

How Can Your Brand Effectively Deal with High MOQs?

You've found the perfect custom bottle, but the supplier's MOQ is just too high for you right now. You feel like you have to either abandon your vision or take a huge financial risk.

Deal with high MOQs by negotiating with the supplier, finding a distributor who breaks bulk, or using the high MOQ to your advantage by planning a multi-product launch with a single, versatile container.

If you're facing an MOQ barrier, don't give up. There are several creative paths you can take to move forward.

1. Negotiation and Partnership

Be open with your supplier. Instead of just asking for a lower MOQ, ask for alternatives. Sometimes we can't lower the quantity for a custom color, but we might have an "overrun" of a similar bottle from a previous job that we can offer at a lower quantity. Or, you could offer to pay a higher price per unit for a smaller test run. A good partner will try to find a solution with you.

2. The Distributor Route

Some larger distributors purchase packaging in massive quantities (millions of units) and then sell it in smaller lots. While you might pay a slightly higher price per piece, you gain access to a wide variety of containers with very low MOQs, sometimes by the case. This is an excellent option for brands that are just starting out.

3. The "One Bottle, Many Products" Strategy

This is an advanced strategy for a planned product line. If you are launching a face serum, an eye cream, and a toner, consider designing one versatile, elegant bottle that can be used for all three products. This allows you to combine your orders to meet the 10,000-unit MOQ. You can then use different colored labels, boxes, or print colors to distinguish between the products. This gives you a cohesive, professional-looking line while meeting manufacturing requirements.

Conclusion

MOQ is a fundamental part of manufacturing, not a barrier. By understanding the reasons behind it and choosing a strategy that fits your brand's size, you can navigate it effectively and build a successful business.

Written by

Mike Lee

You may also be interested in:

How Can You Reduce Packaging Costs Without Compromising Sunscreen Bottle Quality?

You're trying to grow your sunscreen brand, but rising packaging costs are eating into your

The Complete Importing Guide for Spray Bottles: How Can You Simplify the Process?

You worry about complex customs paperwork and your spray bottles arriving damaged. This uncertainty can

From Molding to Assembly: How Does RLAND Ensure Consistent Spray Quality?

You receive a new shipment of spray bottles, but find that some leak and others

Mist Pump vs. Trigger Spray vs. Mini Refill Sprayer: Which One Should You Choose?

You're developing a new spray product, but you're stuck on the packaging. You see mist