How Important is Quality Control in Packaging Manufacturing?

October 31, 2025 • Mike Lee

You've spent months perfecting a product, only to receive a bulk order of packaging with color inconsistencies, scratches, or functional defects. Now you're facing launch delays and costly reprints.

Quality control is the most critical process in manufacturing. It ensures every single unit of your packaging meets the approved standard, protecting your brand's reputation, preventing financial loss, and guaranteeing a consistent customer experience.

Your insights about process transparency are spot-on. I remember a client who was hesitant to work with an overseas supplier due to past experiences with another factory. They told me, "The samples were perfect, but the bulk order was a disaster." They felt powerless and in the dark. We implemented your exact suggestions for them. We started by sending them samples not just from us, but from two other material suppliers so they could compare the finish. During production, we sent them photos from the injection molding machine and videos of the silk printing process every few days. Most importantly, we had them physically sign and return a mass production sample. That signed sample became our "bible." It gave them the ultimate peace of mind, knowing they had a physical benchmark that we were contractually bound to match.

Why is quality control so important in manufacturing?

You might see QC as just another line item on an invoice. You wonder if it's really a necessary expense or just a way for manufacturers to add to the cost.

Quality control is not an expense; it's an investment that protects your revenue. It prevents the massive costs of product recalls, damaged brand reputation, and lost customer loyalty that result from a single bad batch.

Let's think about the real-world impact. A small defect, like a cap that doesn't seal properly, isn't just a packaging flaw. It means your customer's expensive serum could leak in their travel bag. A color that's slightly off-brand can make your product look like a cheap counterfeit on a store shelf. These seemingly small details have huge consequences.

| The Cost of Poor Quality | The Value of Good Quality | |

|---|---|---|

| Financial Loss | You have to pay for the defective units, the cost of re-manufacturing, and the lost sales from being out of stock. | Prevents waste and ensures every dollar spent on inventory is for a sellable, perfect product. |

| Brand Damage | Negative online reviews and social media complaints can permanently tarnish your brand's image of quality. | Every perfect product reinforces your brand's promise of excellence and attention to detail. |

| Customer Erosion | A customer who receives a faulty product is unlikely to ever buy from you again. | Builds trust and loyalty. Customers who trust your quality become repeat buyers and brand advocates. |

In short, quality control isn't about checking boxes; it's about protecting the very foundation of your business.

What are the 4 main types of quality control?

You hear "quality control" but it feels like a vague, behind-the-scenes process. You want to understand the actual steps a good manufacturer takes to ensure your order is perfect.

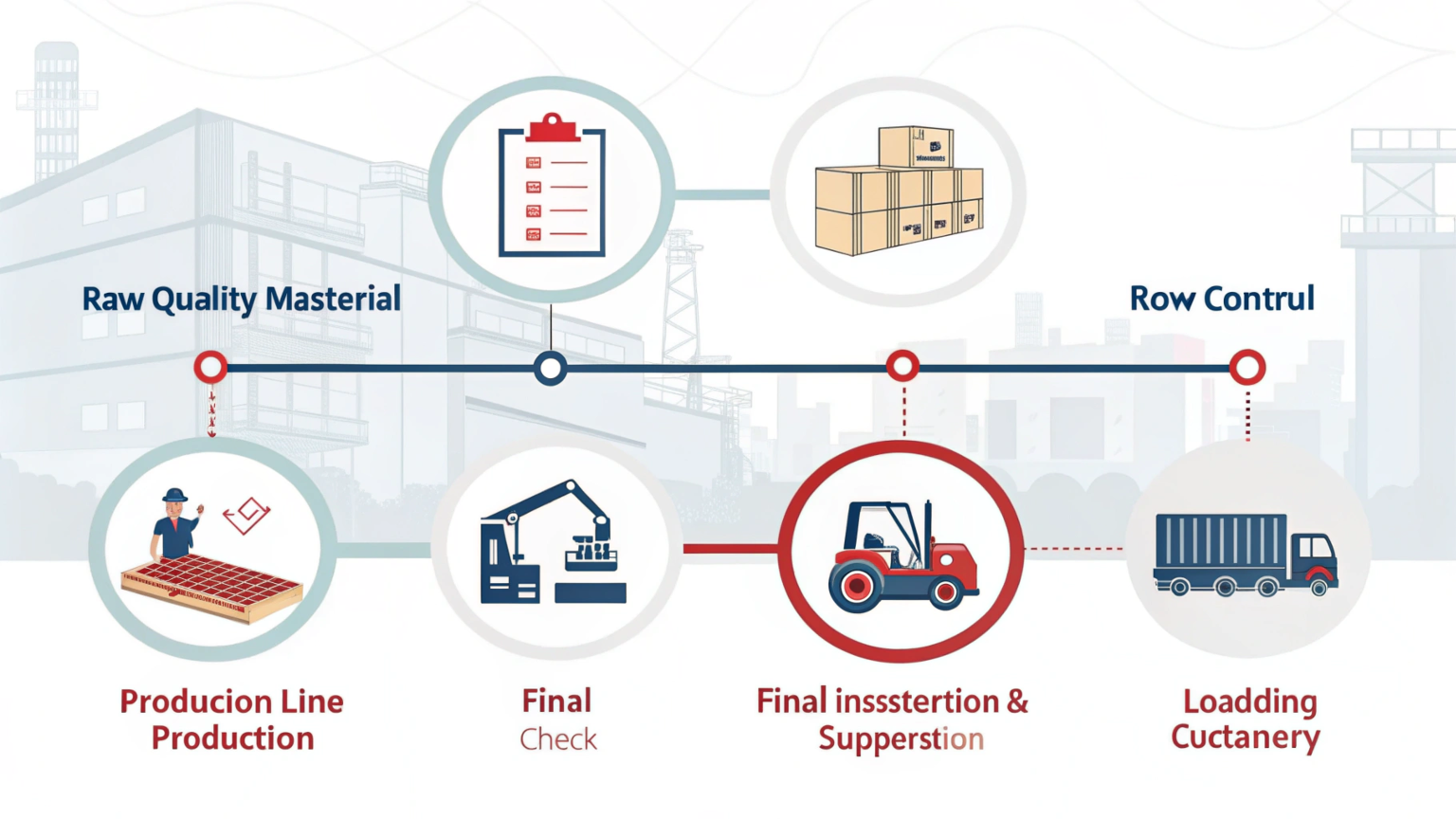

The four primary types of quality control form a complete system: Pre-Production Inspection (checking materials), During Production Inspection (monitoring the process), Pre-Shipment Inspection (final product check), and Container Loading Inspection (ensuring safe transit).

This four-stage process is designed to catch potential issues as early as possible, which is the most efficient and cost-effective way to guarantee quality. Here’s how we implement it, using your insights about transparency at each step.

| QC Stage | Our Action & Your Involvement |

|---|---|

| 1. Pre-Production | Before we make anything, we verify all raw materials (like the specific grade of PP plastic or glass) match the approved specs. This is when we send you a final "Mass Production Sample." You physically hold it, test it, and sign off on it. This signed sample becomes our unbreakable standard. |

| 2. During Production | We don't wait until the end to check. Our line supervisors perform constant checks. We send you photos and videos directly from the factory floor showing the color consistency, print quality, and assembly. You see your product coming to life and can raise any concerns in real-time. |

| 3. Pre-Shipment | Once the full order is complete but before it's packed, we conduct a final, formal inspection. We randomly select a statistically significant number of units and compare them, side-by-side, against your signed Mass Production Sample. We check everything: color, dimensions, function, and finish. |

| 4. Loading Inspection | Quality control extends to how your product is packed. We ensure the cartons are correct, properly sealed, and stacked safely on the pallet to prevent damage. |

This systematic process moves quality control from a mystery to a transparent, collaborative partnership.

What are the quality control processes for packing and shipping?

Your packaging has passed all the manufacturing checks and looks perfect. But you worry that all this hard work could be undone by poor handling during packing and shipping.

Quality control for packing and shipping involves a final verification of quantities, ensuring the use of protective master cartons, and supervising the container loading process to prevent damage from shifting, moisture, or crushing during transit.

The journey from our factory to your warehouse is the final, critical stage where quality can be compromised. Our responsibility doesn't end when the product is made; it ends when it arrives safely in your hands. This final QC stage is all about risk mitigation.

Key Checks Before Departure:

- Quantity Verification: We perform a final count to ensure the number of units packed in each carton and the total number of cartons match your purchase order exactly. There are no surprise shortages.

- Carton & Labeling Check: We confirm that we are using the durable, double-walled shipping cartons specified in the order. We also verify that all shipping labels are correct, clearly legible, and placed properly to ensure smooth customs clearance and delivery.

- Protective Measures: We check that any required internal protection, like dividers or foam sheets, has been used. We ensure the boxes are sealed with high-quality tape to prevent them from opening or being exposed to moisture.

- Loading Supervision: We personally supervise the process of loading the cartons onto the pallet or into the container. We ensure they are stacked correctly to distribute weight evenly and prevent crushing, leaving no room for significant movement.

This final check ensures that the perfect product we manufactured is the perfect product you receive.

Conclusion

Effective quality control is a transparent, multi-stage process that protects your brand and your investment. By partnering with a manufacturer who makes you a part of the process, you turn anxiety into confidence.

Written by

Mike Lee

You may also be interested in:

How Can You Reduce Packaging Costs Without Compromising Sunscreen Bottle Quality?

You're trying to grow your sunscreen brand, but rising packaging costs are eating into your

The Complete Importing Guide for Spray Bottles: How Can You Simplify the Process?

You worry about complex customs paperwork and your spray bottles arriving damaged. This uncertainty can

From Molding to Assembly: How Does RLAND Ensure Consistent Spray Quality?

You receive a new shipment of spray bottles, but find that some leak and others

Mist Pump vs. Trigger Spray vs. Mini Refill Sprayer: Which One Should You Choose?

You're developing a new spray product, but you're stuck on the packaging. You see mist