How Can You Reduce Packaging Costs Without Compromising Sunscreen Bottle Quality?

January 20, 2026 • Mike Lee

You're trying to grow your sunscreen brand, but rising packaging costs are eating into your margins. You feel trapped, believing that the only way to save money is to use cheaper, lower-quality bottles that could leak, fail, and ruin your customers' trust.

You reduce costs not by using inferior materials, but by executing a smarter, holistic strategy. This involves intelligent design optimization, hyper-efficient manufacturing processes, and savvy logistics planning to lower your total landed cost per bottle while maintaining premium quality.

I’ll never forget a call I had with a determined brand owner from Ecuador. She was launching a new sunscreen line and needed a full container's worth of bottles. Her brand was built on quality, but she was facing intense price pressure from local competitors. The initial quotes she received from various suppliers were too high, and she was worried she'd have to compromise. "I can't use a cheap bottle," she told me, "but I have to find a way to make the numbers work." This was a challenge my team and I love. It forced us to look past the obvious and dissect every single component of cost, from the weight of the plastic down to the path the container ship would take across the ocean.

How can you lower bottle costs by changing the design and mold?

You believe a premium bottle must be a heavy bottle. You think that any attempt to reduce its weight will make it feel cheap and flimsy, creating a poor customer experience and risking durability issues with an aggressive sunscreen formula.

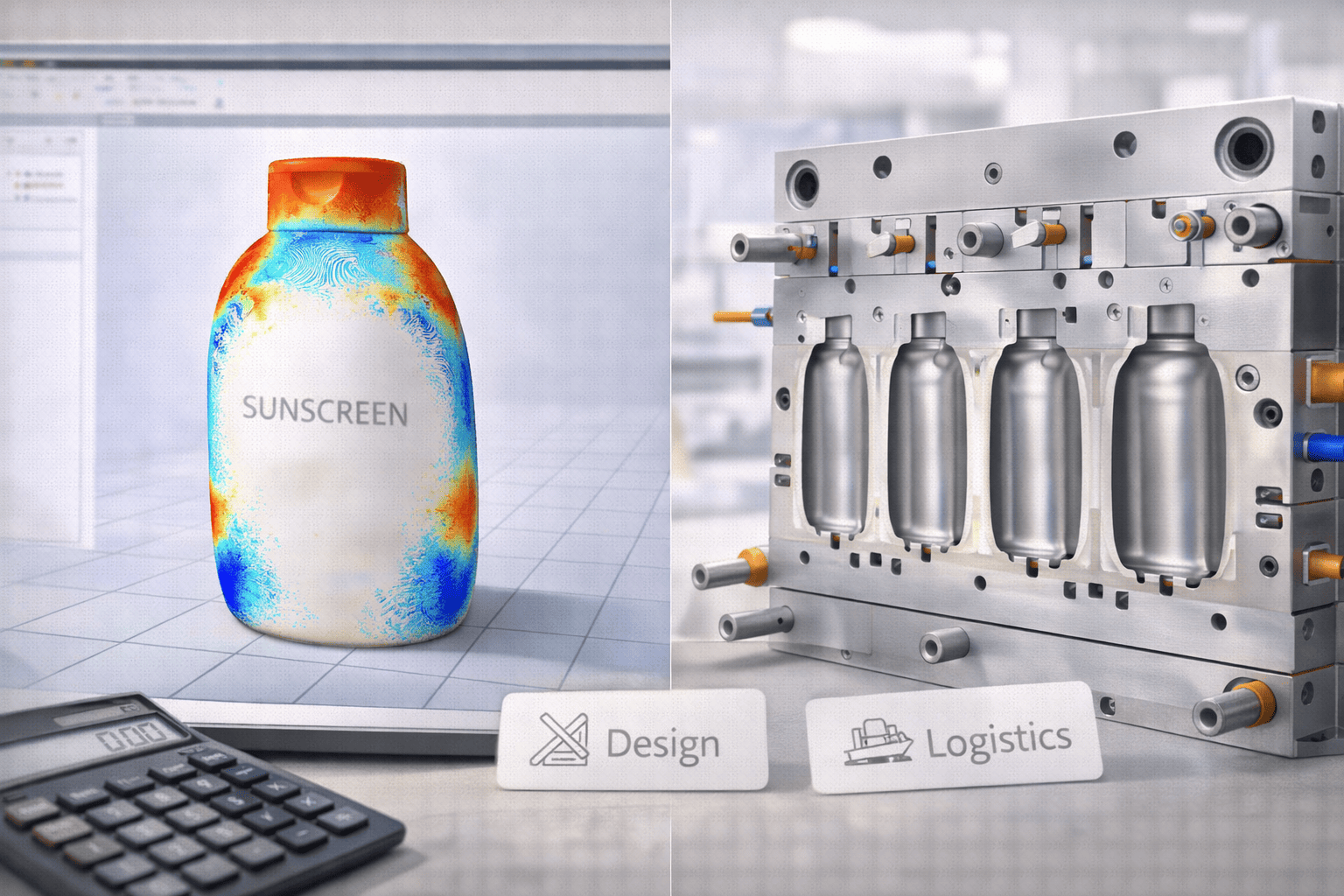

Strategic design changes can drastically cut costs without affecting quality. By using computer simulations for "lightweighting" and optimizing the production mold for speed and efficiency, you use less material and reduce machine time per bottle.

This was our first step with the Ecuadorian client. Her original sample was a beautiful but unnecessarily heavy 28-gram bottle. Our engineers created a 3D model of it and ran a Finite Element Analysis (FEA). This computer simulation shows us exactly how the bottle behaves under stress—when it's squeezed, dropped, or capped. It revealed that a lot of the plastic was in non-structural areas, like the middle of the body panels, where it added weight but not strength. We strategically redesigned the bottle, thinning these areas slightly while reinforcing the critical stress points at the base and neck. We brought the weight down to 25.5 grams. This doesn't sound like much, but a 2.5-gram saving per bottle, multiplied by the hundreds of thousands of units in a container, resulted in a massive reduction in raw material costs.

Then, we looked at the mold itself. The original plan used a 4-cavity mold. We invested in creating an 8-cavity mold for her project. This means that every time the injection molding machine cycles, it produces eight bottles instead of four. This nearly doubled the output per hour, cutting the machine time and energy cost associated with each individual bottle. The final bottle was lighter, cheaper to produce, but felt just as robust and high-quality in the hand.

How can streamlining production processes slash your costs?

You get a unit price from a supplier and assume it’s a fixed number. You don't see the hidden costs of their inefficient workflow—like manual labor, high defect rates, and downtime—that are being passed on to you.

An integrated, automated production line dramatically cuts hidden costs. By seamlessly moving bottles from molding to printing to assembly, you eliminate manual handling, minimize defects, and lower the labor and energy costs baked into your final unit price.

After optimizing the design, we tackled the production flow. Many factories operate in a disconnected way. They’ll mold thousands of bottles, which are then dropped into large bins. Workers then wheel these bins across the factory to a separate printing department. The bottles are manually loaded onto printers, and then moved again for capping. Each step—each time a bottle is handled or sits in a dusty bin—is a chance for it to get scratched, contaminated, or damaged. This leads to a higher defect rate, and the cost of that waste is always built into the price the customer pays.

For our Ecuadorian client's large order, we set up a fully integrated line. Her new 8-cavity mold was placed in a machine connected by a clean, enclosed conveyor belt directly to one of our automated silk-printing machines. As the hot bottles came out of the mold, they were cooled and immediately whisked away to be printed with her single-color logo—a very fast and cost-effective decoration method. From there, another conveyor took them to be capped and packed into master cartons. There was almost zero manual handling of the individual bottles. This reduced our internal defect rate to almost zero, saved significant labor, and increased the overall speed. Those efficiency gains were passed directly to her as a lower unit price.

Can better logistics really lower your packaging unit cost?

You focus only on the factory price (often quoted as "FOB"). You treat shipping and duties as separate, uncontrollable expenses, failing to realize how a smart logistics strategy can dramatically impact the final cost you pay per bottle.

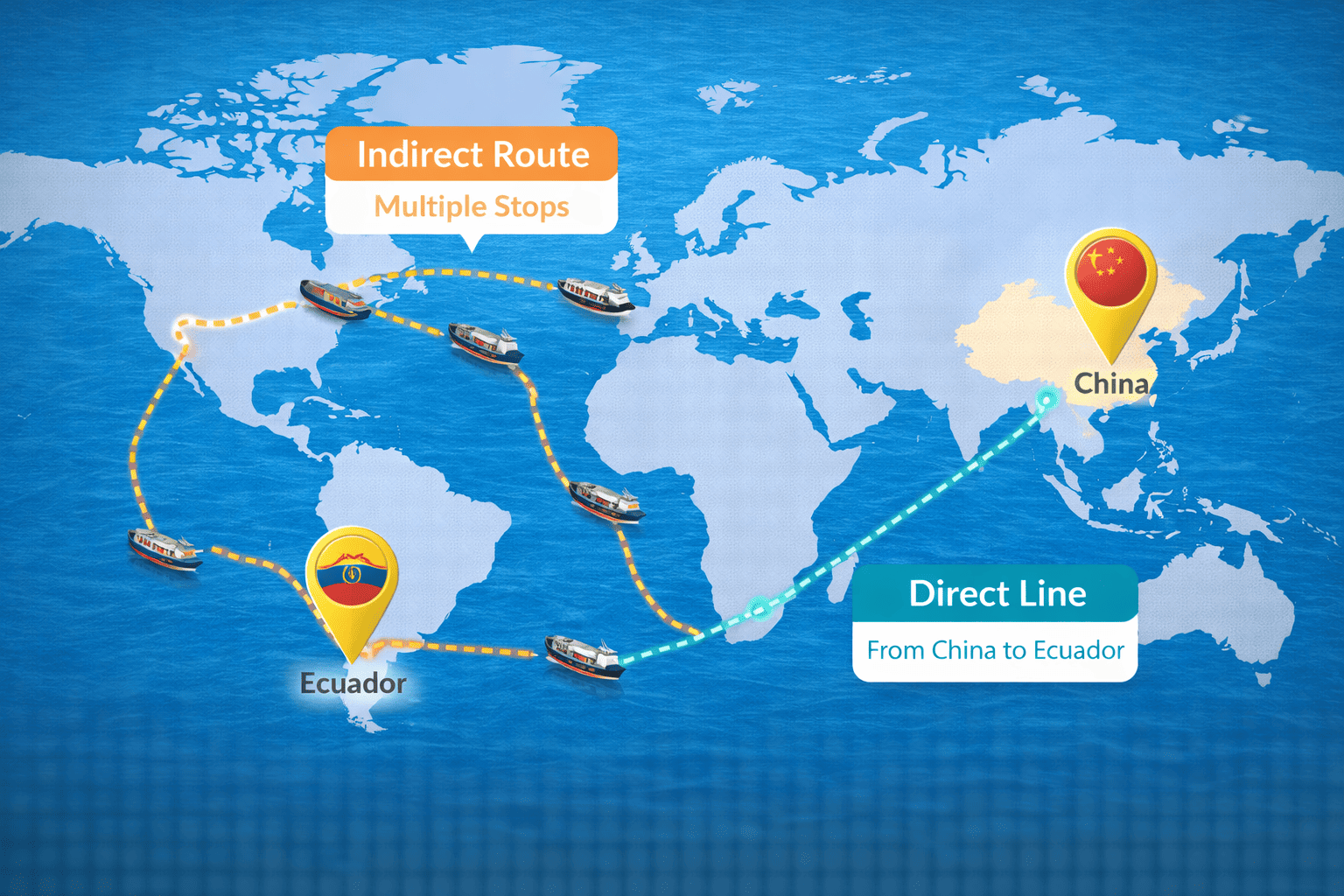

Absolutely. Your true cost is the "landed cost"—the final price per unit after shipping, insurance, and duties. Optimizing container space and finding more efficient shipping routes can cut freight charges by 20% or more, significantly reducing this final cost.

This was the final, crucial saving for our client. She, like many brand owners, was focused on the FOB (Free On Board) price, which is just the cost of the goods at the port of departure. But the real number that matters to her business is the landed cost. Our dedicated logistics team looked at her destination port in Ecuador. The standard shipping routes involved multiple stops and transfers in places like Panama or Colombia. Each transfer adds time, cost, and risk of damage.

Our team leveraged their network to find a carrier offering a direct, non-stop service from our port in Shantou to Guayaquil, Ecuador. This was a game-changer. It shaved nearly two weeks off the transit time, which was a huge cash flow advantage for her. More importantly, the direct route was substantially cheaper because it was more fuel-efficient and involved less port handling fees for the carrier. We also optimized how we packed her master cartons and loaded the container, ensuring not a single cubic inch of space was wasted. This maximized the number of bottles in one shipment. The combination of a cheaper route and a fully packed container significantly lowered the shipping cost per bottle. When she calculated her final landed cost, she was thrilled. The savings from logistics alone made her product viable.

Conclusion

True cost reduction in packaging is a science. It's about a partnership that goes beyond the factory floor to optimize design, automate production, and master global logistics, ensuring you get a premium bottle at the most competitive landed cost.

Written by

Mike Lee

You may also be interested in:

The Complete Importing Guide for Spray Bottles: How Can You Simplify the Process?

You worry about complex customs paperwork and your spray bottles arriving damaged. This uncertainty can

From Molding to Assembly: How Does RLAND Ensure Consistent Spray Quality?

You receive a new shipment of spray bottles, but find that some leak and others

Mist Pump vs. Trigger Spray vs. Mini Refill Sprayer: Which One Should You Choose?

You're developing a new spray product, but you're stuck on the packaging. You see mist

How Can You Choose a Reliable Spray Bottle Manufacturer in China?

You need to source spray bottles from China to stay competitive, but you're terrified. You