How Can You Optimize Logistics for Bulk Cosmetic Packaging Orders?

October 31, 2025 • Mike Lee

You've perfected your formula and finalized your packaging design. Now you're faced with the complex and costly challenge of shipping thousands of units across the globe without delays, damage, or hidden fees.

You optimize logistics by choosing a manufacturing partner with a dedicated in-house export department. They manage all customs, freight, and documentation for you, handling international shipping terms like FOB, CIF, or DDP to simplify your entire process.

Your insight about finding a factory that is an expert in foreign trade is the single most important piece of advice in this entire process. I remember working with a procurement director, much like Shubihika from RAS BEAUTY in India. Her team used to spend dozens of hours every month coordinating between their packaging supplier, a separate freight forwarder, and a customs broker in their home country. There were constant communication gaps and delays. When we showed her that our dedicated export team could handle everything under a single CIF (Cost, Insurance, and Freight) term, delivering directly to her nearest port, it was a complete game-changer. Her team was freed up to focus on marketing their launch, not chasing shipping containers.

How can you optimize both packaging cost and logistics?

You're trying to lower your unit cost, but it feels like high shipping fees and import duties always erase the savings you've worked so hard to achieve on the packaging itself.

You optimize costs by considering logistics during the design phase. This means designing stackable packaging, minimizing empty space with custom inserts, and choosing lightweight materials to reduce freight charges per unit.

The smartest brands understand that the cost of a packaging component isn't just its factory price; it's the total "landed cost" after it arrives at their warehouse. By making small changes in the design stage, you can achieve massive savings in logistics.

| Optimization Strategy | Detailed Explanation |

|---|---|

| Design for Density | The biggest factor in freight cost is volume. We advise clients to favor shapes that nest well, like squares or rectangles over circles, to eliminate wasted air in the shipping carton. We also design components to ship unassembled (e.g., pumps separate from bottles) to achieve the densest possible pack-out, fitting more units into every carton and every container. |

| Material Choice | Weight is critical, especially for air freight. While glass feels premium, it is heavy and fragile. Modern, lightweight materials like PCR PET or PP can provide a premium feel with a significantly lower weight, directly reducing your shipping bill. For every gram we save on the unit, we save kilograms on the pallet. |

| Master Carton Design | We don't just use a generic box. We design the master shipping carton specifically for your product to be as compact as possible. We use custom-fit dividers and inserts that not only protect the product but also ensure there is zero empty space, maximizing the number of units per shipment. |

This integrated approach, where manufacturing and logistics planning happen together, is the key to true cost reduction.

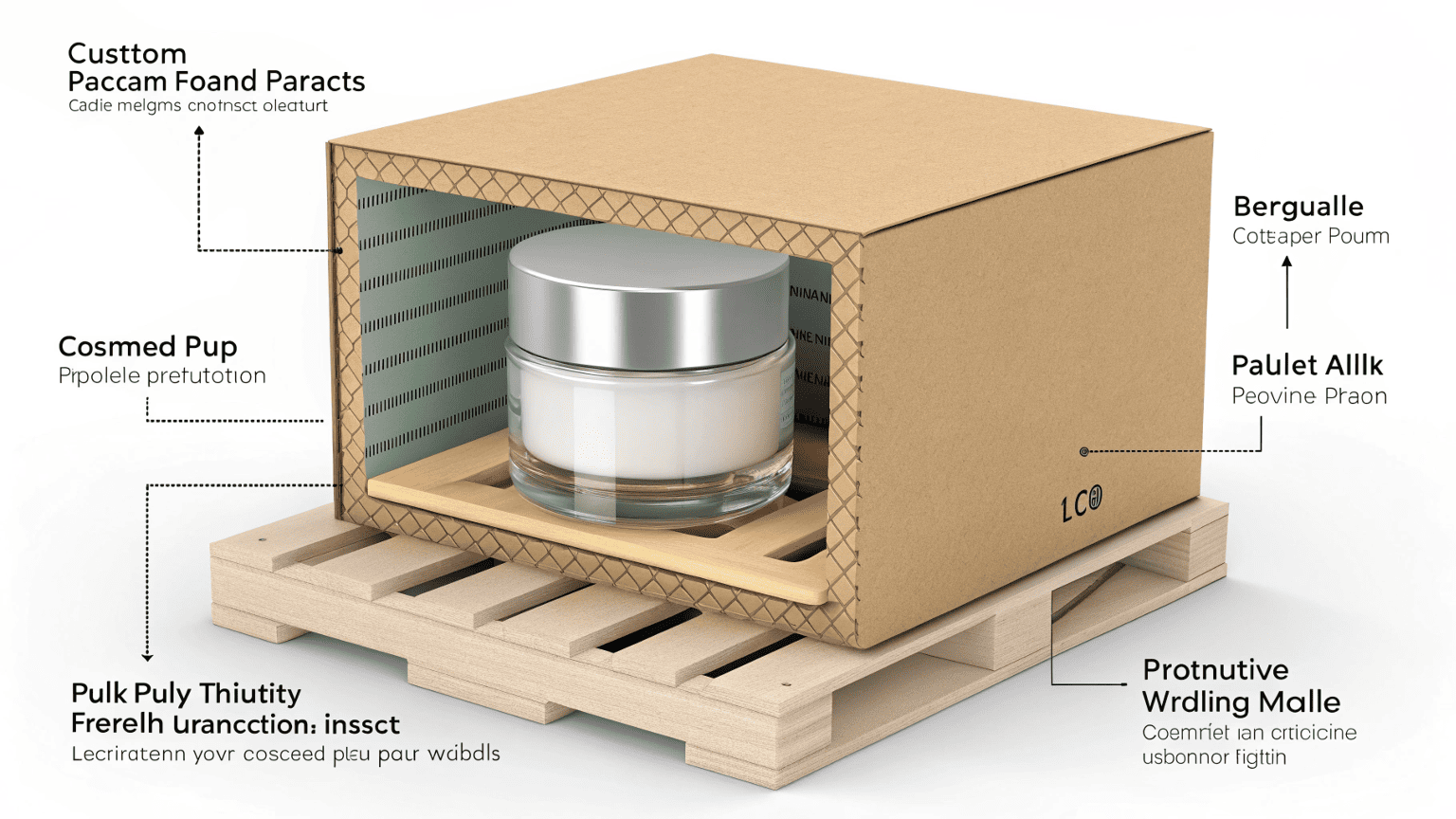

How do you ship fragile cosmetics packaging safely?

You're investing in beautiful glass jars or delicate components. The thought of a whole shipment arriving cracked, scratched, or broken is a nightmare that could derail your product launch.

You ship fragile makeup safely by using a multi-layered protection strategy. This involves custom-fit primary inserts, durable double-walled master cartons, and clear handling instructions to prevent damage during transit.

Ensuring your product arrives in perfect condition is a science. At our facility, product protection is not an afterthought; it's a core part of the packaging development process. We don't just put your items in a box with some bubble wrap. We engineer a complete protective system.

Our Three-Layer Protection System:

- Primary Protection (The Unit Level): This is the first line of defense. For fragile items like glass droppers or jars, we create custom-molded trays or die-cut cardboard inserts. These hold each individual component securely in place, preventing them from touching, vibrating, or shifting during transit. For items with fine finishes, we may use individual soft-foam sleeves.

- Secondary Protection (The Carton Level): Your protected units are then placed into a heavy-duty, double-walled corrugated master carton. We ensure the fit is snug. If any small gaps exist, we use void-fill, like recycled paper or air pillows, to create a solid, immovable block inside the box.

- Tertiary Protection (The Pallet Level): The sealed cartons are then expertly stacked on a pallet. We use interlocking patterns, corner protectors, and heavy-duty shrink wrap to bind the entire pallet into a single, stable unit. This prevents boxes from being crushed or falling during loading and unloading.

This systematic approach minimizes risk and ensures your investment is protected from our factory floor to your warehouse door.

How does optimizing logistics reduce overall costs?

You understand the individual steps, but you want to see the big picture. How does focusing on logistics translate directly to a healthier bottom line for your brand?

Optimizing logistics reduces costs by lowering freight charges through denser packing, minimizing product loss from damage, and saving significant administrative overhead by partnering with a manufacturer that manages the entire export process.

Reducing logistics cost is about more than just finding a cheaper shipping rate. It's about systemic efficiency. Your total cost is a combination of direct and indirect expenses, and a good logistics strategy attacks all of them.

| Cost Category | How Optimization Reduces It |

|---|---|

| Direct Freight Costs | This is the most obvious saving. As discussed, by designing for density and choosing appropriate materials, we fit more products into every shipment. This means you are paying to ship your product, not empty air. Over a large order of 100,000 units, this can translate to thousands of dollars in savings. |

| Product Loss & Damage Costs | A 2% damage rate on a $50,000 order is a $1,000 direct loss, not to mention the cost of delays and stockouts. Our engineered protection systems aim for a near-zero damage rate, eliminating this hidden expense and ensuring every dollar you spend on packaging ends up as a sellable product. |

| Administrative & Labor Costs | This is the hidden killer. Your team's time is valuable. By using a partner with a dedicated export department, you eliminate the hours your staff would spend finding quotes, coordinating with multiple vendors, and managing complex customs paperwork. This "soft cost" saving is often the most significant of all. |

By viewing logistics as an integral part of production, you transform it from a painful expense into a competitive advantage.

Conclusion

Stop thinking of logistics as a separate, difficult step. By choosing a manufacturing partner who is an expert in global trade, you can build efficiency and safety directly into your packaging.

Written by

Mike Lee

You may also be interested in:

How Can You Reduce Packaging Costs Without Compromising Sunscreen Bottle Quality?

You're trying to grow your sunscreen brand, but rising packaging costs are eating into your

The Complete Importing Guide for Spray Bottles: How Can You Simplify the Process?

You worry about complex customs paperwork and your spray bottles arriving damaged. This uncertainty can

From Molding to Assembly: How Does RLAND Ensure Consistent Spray Quality?

You receive a new shipment of spray bottles, but find that some leak and others

Mist Pump vs. Trigger Spray vs. Mini Refill Sprayer: Which One Should You Choose?

You're developing a new spray product, but you're stuck on the packaging. You see mist