How Can You Effectively Manage Lead Times in Cosmetic Packaging Production?

September 29, 2025 • Mike Lee

You placed your packaging order weeks ago, but the delivery date keeps getting pushed back. Your product launch is at risk, and you feel powerless, waiting for updates from a supplier who isn't communicating clearly.

Effective lead time management requires clear initial timelines, regular communication checkpoints, and a collaborative partnership with your supplier. Proactive planning, not reactive chasing, is the key to launching on time.

This is one of the biggest sources of stress I see with new clients. They come to us after a damaging experience where a supplier's missed deadlines threw their entire marketing and retail schedule into chaos. As you've noted, the solution is rooted in communication. My best client relationships are partnerships. We agree on a timeline upfront, and I make it a point to send progress updates—often with photos and videos from the production floor—at key milestones. This transparency isn't just for reassurance; it allows us to spot and solve potential issues together, long before they can cause a delay.

What exactly is the lead time for packaging?

You hear the term "lead time" and assume it's just the time it takes to manufacture your order. You overlook the crucial steps like mold creation, material sourcing, and quality checks that happen before production even starts.

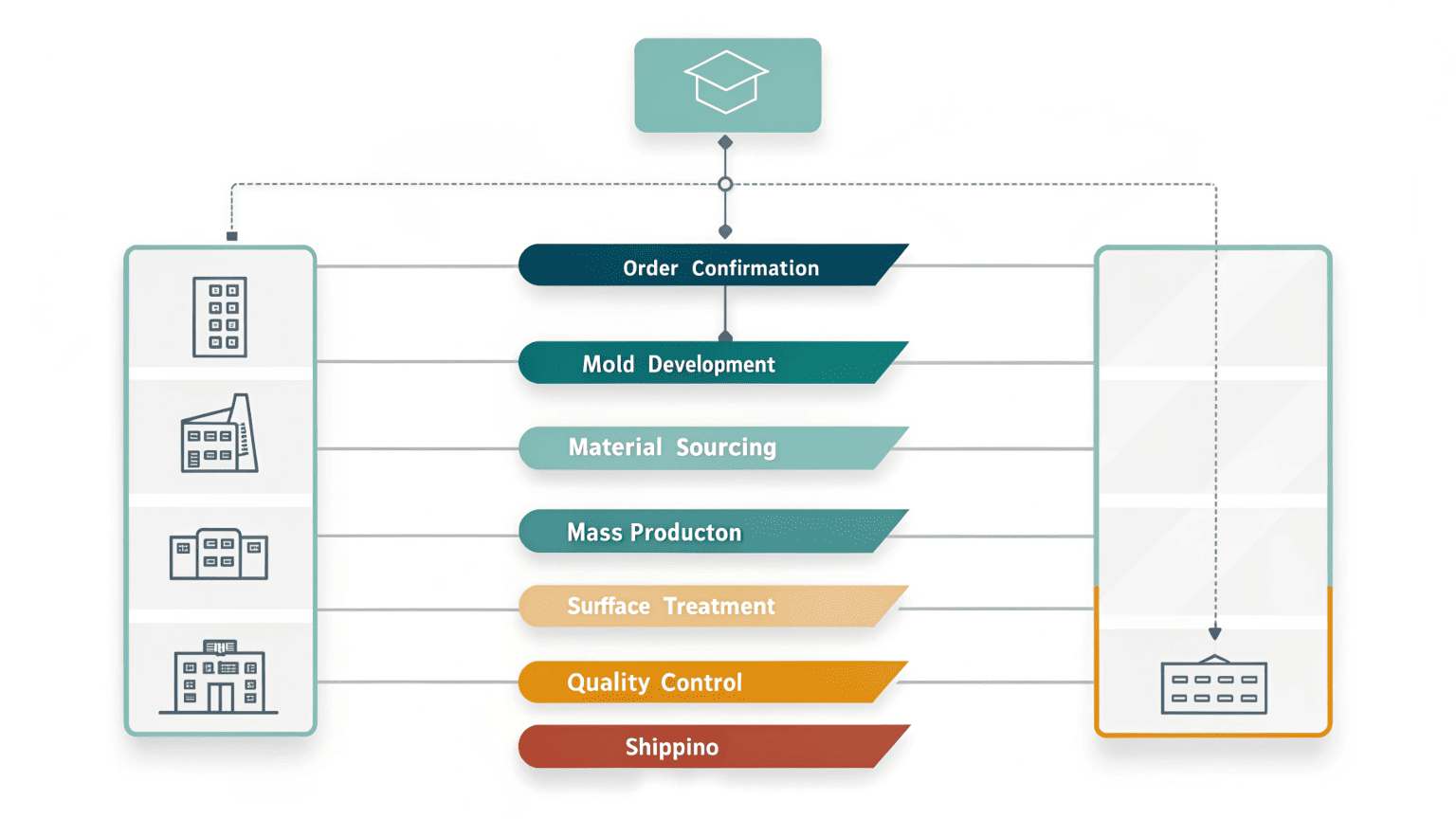

Lead time is the total time elapsed from the moment you place an order with your supplier until you receive the finished goods. It includes pre-production (molds, materials), production (molding, finishing), and post-production (assembly, QC, shipping).

Understanding what goes into lead time is the first step to managing it. It’s not a single block of time; it's a sequence of dependent stages. A delay in one stage will inevitably push back all the subsequent ones.

Breaking Down the Lead Time

At Rland, we provide our clients with a clear breakdown, so there are no surprises. A typical project timeline looks like this:

- 1. Mold Development (if custom): 20-30 days. This is often the longest single phase for a new project. It involves designing, fabricating, and testing a new injection or blow mold. If you choose one of our 1,000+ existing stock molds, you skip this entirely.

- 2. Material Sourcing & Color Matching: 5-7 days. We order the specific plastic resin (PET, PP, etc.) and pigments needed for your project and create lab dips for your color approval.

- 3. Mass Production: 15-25 days. This is the actual manufacturing phase where our 20+ injection and 10+ blow molding machines are running. The exact time depends on your order quantity.

- 4. Surface Treatment & Post-Processing: 7-10 days. This includes processes like silk printing, hot stamping, or UV spraying. Each additional process adds time.

- 5. Quality Control & Packing: 3-5 days. Our team conducts final inspections and prepares the goods for shipment.

As you can see, a "30-day lead time" isn't 30 days of just making bottles. It's a complex, multi-stage process.

How do you calculate lead time for production scheduling?

You get a lead time estimate of "45 days" from a supplier. You mark your calendar for 45 days from today, not realizing this doesn't account for approvals, revisions, or shipping transit time.

To calculate a realistic lead time, sum the supplier's estimates for each production stage, and then add buffer time for approvals, potential revisions, and shipping. Always confirm if the lead time starts from order confirmation or artwork approval.

Calculating an accurate timeline is a collaborative effort between you and your supplier. A simple number isn't enough; you need to understand the variables.

The Formula for Realistic Scheduling

Here is a more robust way to think about your total project timeline:

Total Time = (Mold Time) + (Sample Approval Time) + (Production Lead Time) + (Shipping Time)

| Let's break this down with a practical example: | Stage | Estimated Time | Your Role / Key Variable |

|---|---|---|---|

| Mold Creation | 25 days | Initial design complexity. | |

| Sample Approval | 7 days | This is on you! How quickly can you test the samples and provide feedback? We can send samples in 72 hours with 3D printing, but if feedback takes a week, the project stalls. | |

| Production Lead Time | 30 days | This is the supplier's core manufacturing time, covering everything from molding to printing as we discussed earlier. | |

| Sea Freight Shipping | 25 days | This varies hugely by destination. From China to the US West Coast might be 20 days; to Europe, it could be 30+. Air freight is faster but much more expensive. | |

| Buffer/Contingency | 10 days | Always add a buffer for unforeseen delays like customs inspections or port congestion. |

Total Realistic Timeline: 25 + 7 + 30 + 25 + 10 = 97 days.

As you can see, the initial "30-day production lead time" is only a fraction of the total picture. A good account manager will help you build this complete timeline.

How can you reduce the lead time in production?

Every day of delay costs you money and market opportunity. You are constantly searching for ways to speed up the production process without sacrificing the quality of your packaging.

Reduce lead times by making quick decisions on samples, choosing stock molds instead of custom ones, simplifying your design, and working with an integrated supplier who performs all processes in-house.

While some parts of the lead time are fixed, there are several levers you can pull to significantly shorten your time to market. This is where your choices as a brand owner have the biggest impact.

1. Be Decisive with Approvals

The single biggest delay we see on the client side is slow approval of samples and artwork. The factory is on hold until you give the green light. To speed this up, have your testing and evaluation process ready to go before the samples even arrive. Quick, clear feedback is crucial.

2. Leverage Stock Molds

Developing a custom mold is a major time investment. If speed is your priority, ask your supplier about their stock mold options. At Rland, we have over 1,000 existing molds that are ready for production immediately. You can still create a unique look through color and surface decoration, but you cut 20-30 days from your timeline instantly.

3. Simplify Design and Finishing

Every additional finishing process adds time. A bottle with a gradient spray, hot stamping, and silk printing will take longer than a bottle with just a single-color print. If you need a quick turnaround, consider a simpler yet elegant design.

4. Choose an Integrated Supplier

Working with a supplier who does everything in-house is a massive advantage. If your supplier has to send your bottles to a different factory for printing, and another one for assembly, you add logistical complexity and time. Our factory integrates injection molding, blow molding, silk printing, and assembly under one roof. This tight control allows us to streamline the process and eliminate the "dead time" of shipping components between different facilities.

Conclusion

Mastering lead time comes down to proactive collaboration. By understanding the process, planning realistically, and communicating constantly with an integrated supplier, you can launch your products on time, every time.

Written by

Mike Lee

You may also be interested in:

How Can You Reduce Packaging Costs Without Compromising Sunscreen Bottle Quality?

You're trying to grow your sunscreen brand, but rising packaging costs are eating into your

The Complete Importing Guide for Spray Bottles: How Can You Simplify the Process?

You worry about complex customs paperwork and your spray bottles arriving damaged. This uncertainty can

From Molding to Assembly: How Does RLAND Ensure Consistent Spray Quality?

You receive a new shipment of spray bottles, but find that some leak and others

Mist Pump vs. Trigger Spray vs. Mini Refill Sprayer: Which One Should You Choose?

You're developing a new spray product, but you're stuck on the packaging. You see mist