From Molding to Assembly: How Does RLAND Ensure Consistent Spray Quality?

December 29, 2025 • Mike Lee

You receive a new shipment of spray bottles, but find that some leak and others have a poor spray. This inconsistency damages your brand and frustrates your customers, forcing you to deal with complaints and returns.

We ensure consistent spray quality by focusing on three areas: using high-precision molds and modern machinery, sourcing only premium raw materials with SGS certification, and conducting rigorous final inspections, including visual checks, drop tests, and vacuum leak tests.

I remember a brand that came to us in a panic. Their previous supplier had delivered 100,000 spray bottles where the pump wouldn't screw on properly. Their entire product launch was on hold. We discovered the issue was a worn-out mold that was producing parts with inconsistent threads. It was a costly lesson for them about how tiny, unseen details can cause huge problems. This is why we are obsessed with controlling the entire process, from the very first step to the last. Our reputation, and yours, depends on it.

How is the quality of our molded parts controlled?

You wonder how it's possible to make a million bottles and ensure the first one is identical to the last. You suspect that quality must vary across such a large production run, creating a risk for your brand.

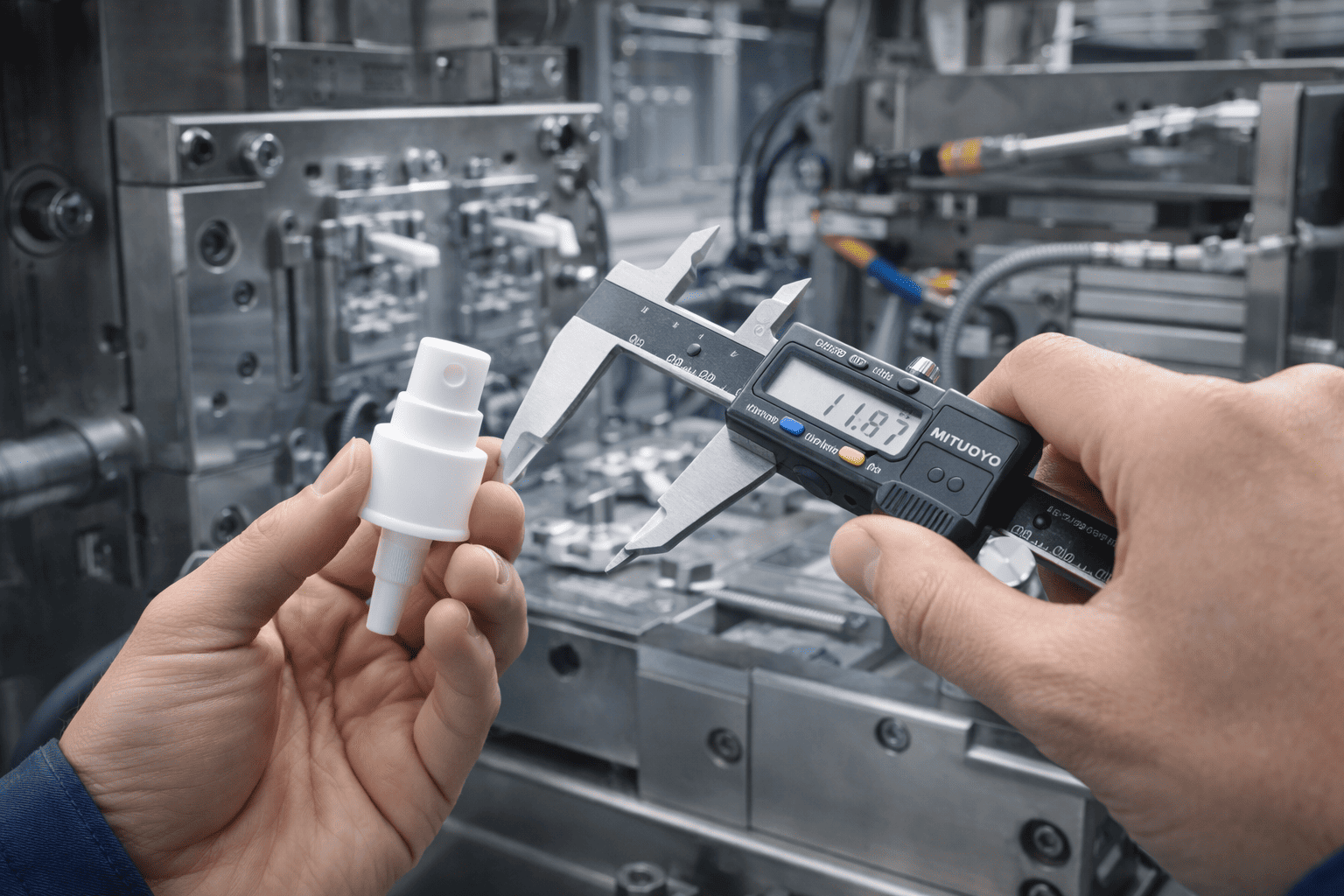

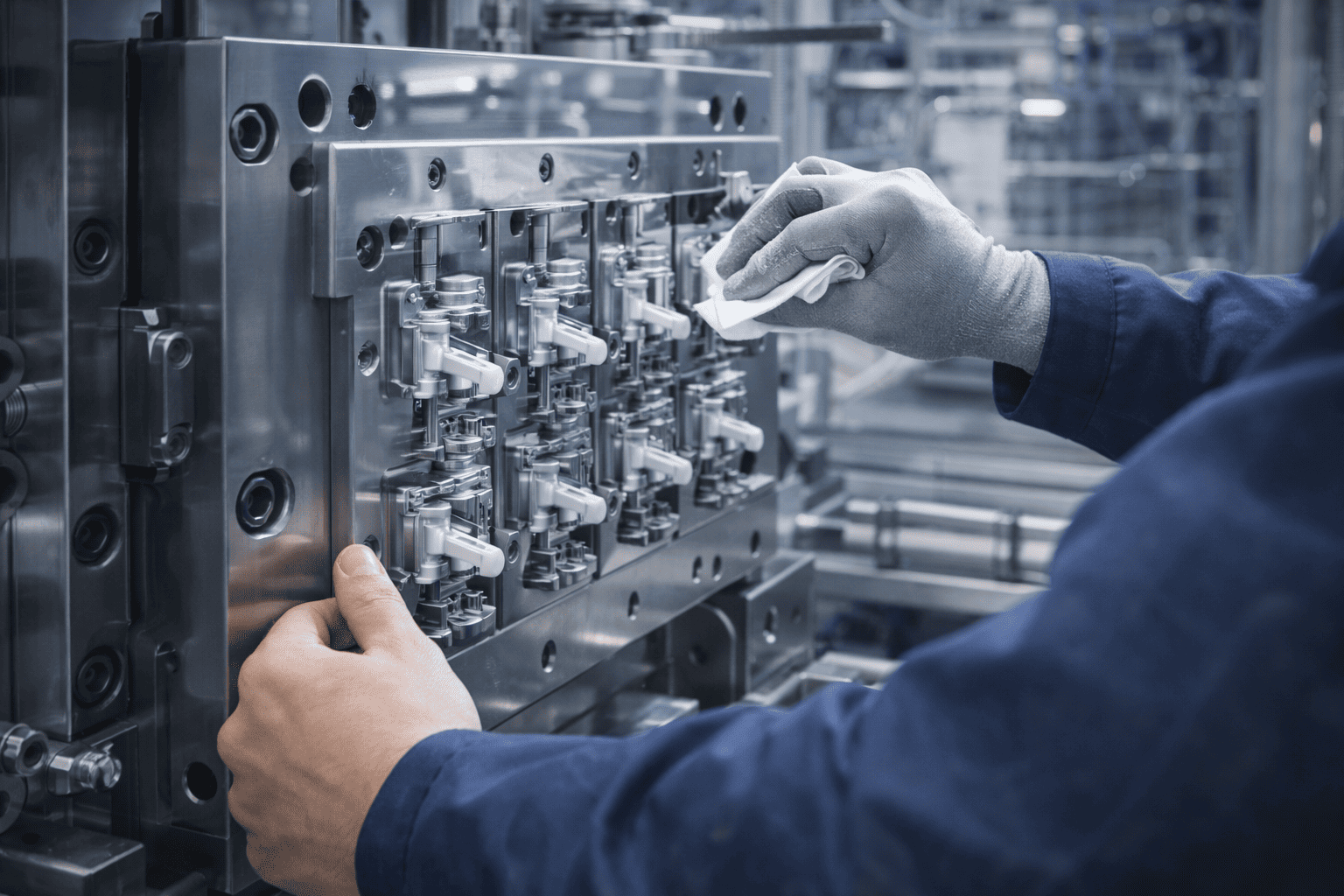

We control quality by starting with superior inputs. This means using meticulously maintained, high-precision molds and state-of-the-art injection molding machines. We believe that a perfect final part can only come from perfect initial conditions.

The quality of a molded part is determined long before the plastic is ever injected. It starts with the mold itself. A mold is not a "set it and forget it" tool. It requires a strict schedule of maintenance, cleaning, and calibration. Even tiny amounts of wear can affect the dimensions of a part, leading to issues like leaking caps or inconsistent wall thickness. We use high-grade steel for our molds to ensure longevity. Alongside the mold is the injection molding machine. Our facility uses 20 high-precision machines that provide consistent temperature, pressure, and speed. This ensures that every part is formed under the exact same conditions, eliminating variables that can lead to defects. By focusing intensely on the quality and maintenance of our core equipment, we control quality at the source, preventing problems rather than just trying to catch them later.

What are the typical quality inspections for our injection molded parts?

You've approved a final sample, but how do you know the one-millionth part produced will be just as good? You worry that defects might slip through during mass production, ending up in your customers' hands.

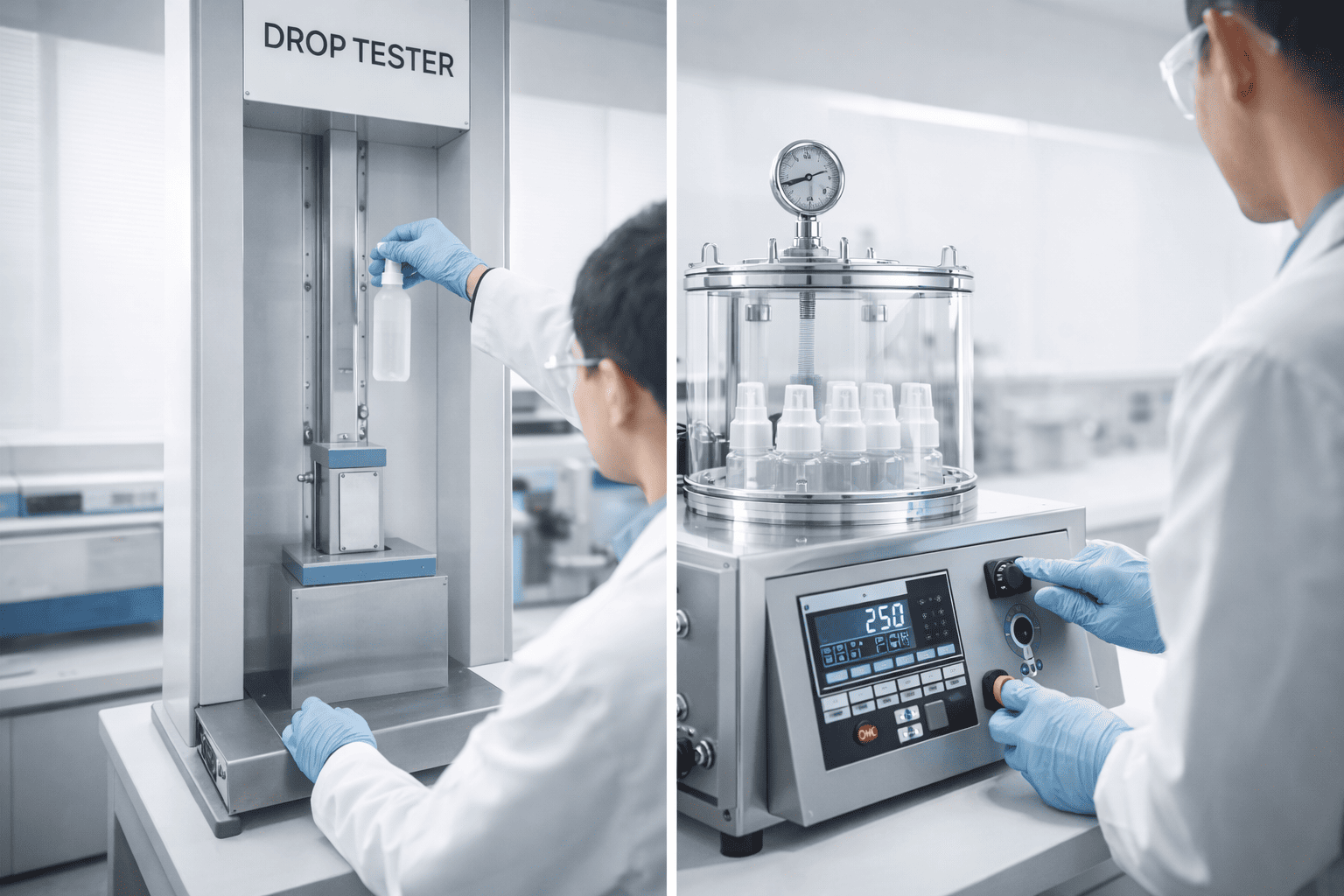

We perform a multi-stage inspection on every batch. This includes detailed visual checks for aesthetic defects, physical drop tests for durability, and vacuum leak tests to guarantee a perfect seal between the bottle and the sprayer.

A perfect part from the mold is just the beginning. After production, every batch goes through a series of demanding quality control checks to confirm its real-world performance. Our process is built on the three pillars you mentioned, as these tests simulate the entire life of the product.

| Inspection Type | What We Do | Why It's Critical for Spray Quality |

|---|---|---|

| Visual Inspection | Trained inspectors check parts under bright lighting for surface imperfections like scuffs, flow lines, or color inconsistencies. | Ensures the bottle meets your brand's aesthetic standards. A premium look suggests a premium product inside. |

| Drop Test | We drop filled bottles from a standard height onto a hard surface, checking for cracks or breakage. | Guarantees that the bottle is durable enough to survive shipping and accidental drops by the customer, preventing leaks and product loss. |

| Vacuum Leak Test | We place assembled bottles in a vacuum chamber. This simulates pressure changes (like in air travel) to see if any liquid escapes. | This is the ultimate test for a spray bottle. It confirms a perfect seal, ensuring your product won't leak in a customer's purse or luggage. |

What other factors contribute to part quality during injection molding?

You understand that machines and inspections are important. But you also know that there must be other, less obvious factors that separate an average manufacturer from a great one. What are those hidden ingredients?

Beyond machines, the two most critical factors are the quality of the raw materials and the skill of our technical team. Using certified, pure raw materials and having experienced operators ensures that the process runs flawlessly from start to finish.

You can have the best mold and the best machine in the world, but if you put poor-quality plastic into it, you will get a poor-quality part. This is why we are incredibly strict about our raw materials. We only use premium, virgin pellets from trusted suppliers, and we require SGS test reports to verify their purity and properties. This guarantees that the final product is strong, clear, and safe for contact with cosmetics. The other "secret ingredient" is our people. Our machine operators and quality control technicians have years of experience. They know how to fine-tune the machines for different materials and can spot potential issues before they become major problems. This combination of superior materials and human expertise is the final piece of the puzzle that ensures every spray bottle we produce is something we are proud to put our name on.

Conclusion

Consistent spray quality is not an accident. It is the result of a rigorous system that controls mold quality, uses certified raw materials, and performs multi-stage inspections on every single batch we produce.

Written by

Mike Lee

You may also be interested in:

How Can You Reduce Packaging Costs Without Compromising Sunscreen Bottle Quality?

You're trying to grow your sunscreen brand, but rising packaging costs are eating into your

The Complete Importing Guide for Spray Bottles: How Can You Simplify the Process?

You worry about complex customs paperwork and your spray bottles arriving damaged. This uncertainty can

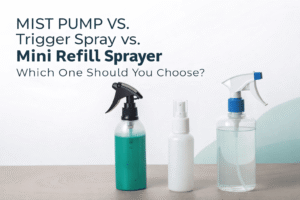

Mist Pump vs. Trigger Spray vs. Mini Refill Sprayer: Which One Should You Choose?

You're developing a new spray product, but you're stuck on the packaging. You see mist

How Can You Choose a Reliable Spray Bottle Manufacturer in China?

You need to source spray bottles from China to stay competitive, but you're terrified. You