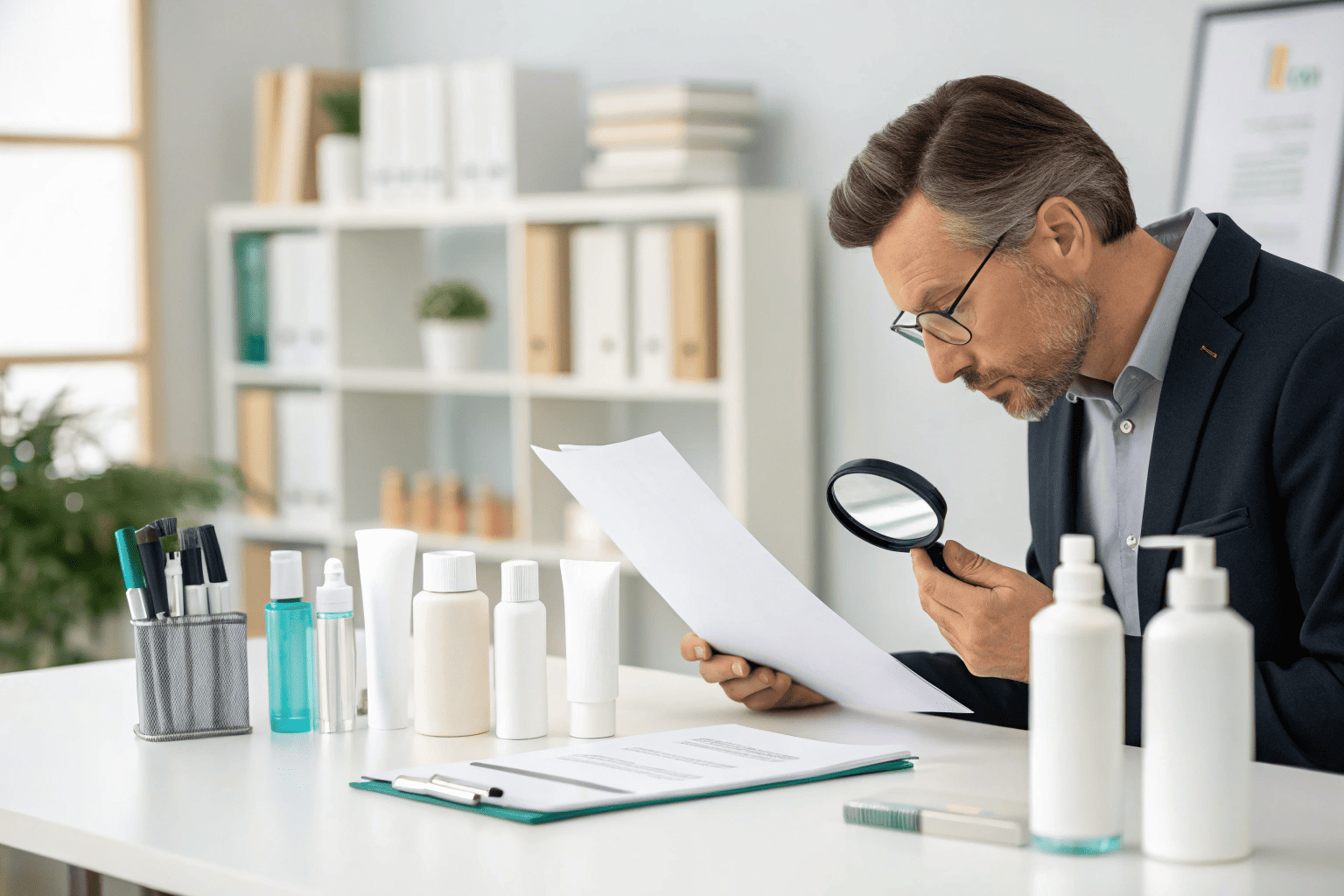

Material Safety in Cosmetic Packaging: What B2B Buyers Must Check?

September 9, 2025 • Mike Lee

You've approved a beautiful packaging sample. But the bulk order arrives, and it feels different. Or worse, your product starts to discolor, all because the supplier secretly used cheap, recycled materials.

Buyers must check material origin and authenticity. Demand a Certificate of Compliance and a Material Safety Data Sheet (MSDS) for the raw plastic pellets. Be cautious with dark or black packaging, as it can hide impure recycled content.

At Rland, I've seen brands get burned by this. A supplier cuts corners, mixes in undeclared recycled materials to save a few cents, and your entire product line is compromised. Trust is good, but verification is better. Knowing exactly what to demand from your packaging partner is the only way to protect your product, your customers, and your brand's reputation.

How to Inspect Cosmetic Packaging: A Complete B2B Quality Guide?

The golden sample looked perfect, but you have thousands of units on the way. You're worried that you don't know how to spot the hidden defects that can lead to disaster.

To truly inspect cosmetic packaging, go beyond a simple visual check. You must demand and verify the raw material documentation from your supplier. This includes the MSDS and proof that the material source is a reputable manufacturer.

This is a non-negotiable part of our process at Rland, and it should be for you too. A physical bottle can hide its true origin, but the paperwork can't. Here is my proven, three-step inspection framework for any B2B buyer.

Step 1: Demand Key Documentation

Before you even approve a tool, demand to see the paperwork for the specific raw material batch that will be used. The two most important documents are:

- Material Safety Data Sheet (MSDS/SDS): This details the chemical properties and safety information of the plastic.

- Certificate of Compliance (CoC): This is a declaration from the manufacturer that the product meets required standards.

Step 2: Vet the Raw Material Supplier

Don't just trust the documents from your packaging factory. Check who manufactures the raw plastic pellets. They should be from globally recognized, legitimate chemical companies. If your supplier is cagey about where they source their raw plastic, that's a huge red flag. A reputable factory is proud of its material sources.

Step 3: The Color Test

This is a critical insight I always share. Whenever possible, choose light-colored or transparent packaging. It is much harder to hide impurities or recycled content in a white or clear bottle. Black plastic, on the other hand, is the easiest way to hide low-quality materials. Recycled plastics often have specks or color inconsistencies, and black pigment masks this perfectly.

| Color Choice | Pro | Con (Risk) |

|---|---|---|

| White/Clear/Light | Easy to spot impurities | Might show product discoloration more |

| Black/Dark | Hides product light sensitivity | Easily hides cheap, recycled material |

Cosmetic Packaging Safety: Key Considerations and Insights?

You see terms like "BPA-free" and "FDA-compliant," but you're not sure what they really mean. You're worried you might overlook a crucial safety standard that could get your product pulled from shelves.

Packaging safety means ensuring two things: the material is compliant with regulations (like FDA or EU standards) and it is chemically compatible with your specific formula. This prevents harmful chemicals from leaching into your product and ensures consumer safety.

This goes beyond just the quality of the plastic; it's about its suitability and legality for your product and market. A beautiful, high-quality bottle is useless if it's not safe or compliant.

Regulatory Compliance is Non-Negotiable

Different markets have different rules. For example:

- USA: Materials that come into contact with the product often need to meet FDA (Food and Drug Administration) standards for safety.

- Europe: You need to be aware of REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulations, which control the use of certain chemical substances.

- California: Proposition 65 requires businesses to provide warnings about significant exposure to chemicals that cause cancer or birth defects.

A good supplier will not only be aware of these regulations but will also be able to provide the testing and documentation to prove their materials are compliant for your target market.

Ensuring Chemical Compatibility

This is a crucial step many brands miss. You must test your specific formula with the a sample of the packaging. Some active ingredients in skincare can react with certain types of plastic over time, causing the bottle to warp or the formula to break down. A full stability test, where you store your product in the final packaging for several weeks at different temperatures, is the only way to be 100% sure they are compatible. Never skip this test.

A B2B Buyer's Guide to Novel Cosmetic Packaging Bottle: Price,...?

You found a supplier offering an incredibly low price. It's tempting to accept the offer to save on costs, but you have a nagging feeling that it's too good to be true.

An unusually low price is the biggest red flag. It almost always means the supplier is using subpar or undeclared recycled materials, which compromises safety and quality. A legitimate supplier using virgin resin from a top-tier manufacturer cannot compete on price alone.

I get it. Budgets are tight. But in my years of experience, I can tell you that chasing the absolute lowest price in packaging is one of the most expensive mistakes a brand can make. Here's what that low price tag often hides.

The Hidden Cost of "Cheap"

That amazing price is often achieved by mixing in post-consumer recycled (PCR) plastic or factory floor scraps without telling you. Now, using PCR can be a great, sustainable choice when it is done transparently and with certified, properly processed materials. The problem is the undisclosed use of dirty, uncertified recycled content. This can lead to:

- Inconsistent Quality: Some bottles will be weaker than others.

- Contamination: The recycled material could contain chemical residues that leach into your product.

- Failed Batches: A whole production run could be ruined, costing you far more than you saved on packaging.

The Hallmarks of a Quality Supplier

Instead of focusing only on price, look for signs of a quality partner. A legitimate, reliable manufacturer:

- Is transparent about their raw material sources.

- Proudly provides all necessary compliance and safety documentation.

- Encourages stability testing with your formula.

- Has prices that reflect the market cost of high-quality, virgin materials.

- Explains why a certain material is the right choice, beyond just its cost.

Remember, the bottle is the home for your product. Paying a fair price for a safe, reliable home is an investment, not an expense.

Conclusion

Verify your packaging's material source with documentation. Watch out for low prices and dark colors that hide recycled content. Partner with suppliers who prioritize transparency and safety over being the cheapest option.

Written by

Mike Lee

You may also be interested in:

How Can You Reduce Packaging Costs Without Compromising Sunscreen Bottle Quality?

You're trying to grow your sunscreen brand, but rising packaging costs are eating into your

The Complete Importing Guide for Spray Bottles: How Can You Simplify the Process?

You worry about complex customs paperwork and your spray bottles arriving damaged. This uncertainty can

From Molding to Assembly: How Does RLAND Ensure Consistent Spray Quality?

You receive a new shipment of spray bottles, but find that some leak and others

Mist Pump vs. Trigger Spray vs. Mini Refill Sprayer: Which One Should You Choose?

You're developing a new spray product, but you're stuck on the packaging. You see mist