Your sunscreen leaks and pumps clog, leading to customer complaints and lost sales. These costly failures are preventable by understanding the unique challenges of sunscreen packaging.

Sunscreen packaging often fails because aggressive formulas degrade materials, mineral particles clog pumps, and pressure changes from heat or travel cause leaks. Unlike other skincare, sunscreen demands specialized materials and rigorous testing to withstand these harsh conditions.

I'll never forget the panic call from a client. They had just launched a new sunscreen spray in time for summer. The product was fantastic, but the bottles were a disaster. They were getting dozens of emails about bottles leaking in beach bags and pumps clogging after just a week. They had chosen a standard bottle to save on costs, assuming it would be fine. That one decision cost them thousands in returns and damaged their brand's reputation right at launch. It was a brutal lesson: sunscreen isn't just another cosmetic. It's an aggressive product used in extreme environments, and its packaging has to be up to the challenge.

Why does my sunscreen leak in my bag?

You've created a perfect travel-sized sunscreen, but customers complain it leaked all over their luggage. You feel helpless as negative reviews about messy leaks start piling up online.

Your sunscreen leaks because of inadequate sealing, pressure changes during air travel, or weak bottle walls. A proper seal isn't a feature; it's a fundamental requirement that needs specific engineering and testing.

Leakage is the number one enemy of sunscreen packaging. When a customer trusts your product enough to throw it in their expensive handbag or luggage, a leak isn't just an inconvenience—it's a betrayal. This usually happens for a few key reasons. The first is a poor Seal Interface between the bottle neck and the pump; even a microscopic gap can cause a leak under pressure. The second is Pressure Changes, especially during flights, which can force the product out. Finally, Weak Bottle Walls can deform when squeezed in a full bag, breaking the seal. To avoid this, we perform rigorous testing. We conduct inverted storage tests, vibration simulations that mimic transport, and vacuum chamber tests to simulate air travel. We use pumps with reinforced sealing rings and design caps with locking mechanisms. It's a comprehensive approach to ensure the bottle remains sealed no matter what.

Why did my sunscreen pump suddenly stop working?

Your customer loved their sunscreen for the first few weeks, but now the pump is stiff and clogged. They blame your product, thinking the formula is bad, when the real culprit is the pump itself.

The pump stopped working because the sunscreen formula reacted with its internal parts or mineral particles clogged the nozzle. Sunscreen requires a pump specifically designed for its viscosity and chemical composition to ensure long-term performance.

A pump failing after a few weeks is a classic sunscreen packaging problem. We see this all the time. The reasons are almost always chemical or physical.

Causes of Pump Failure

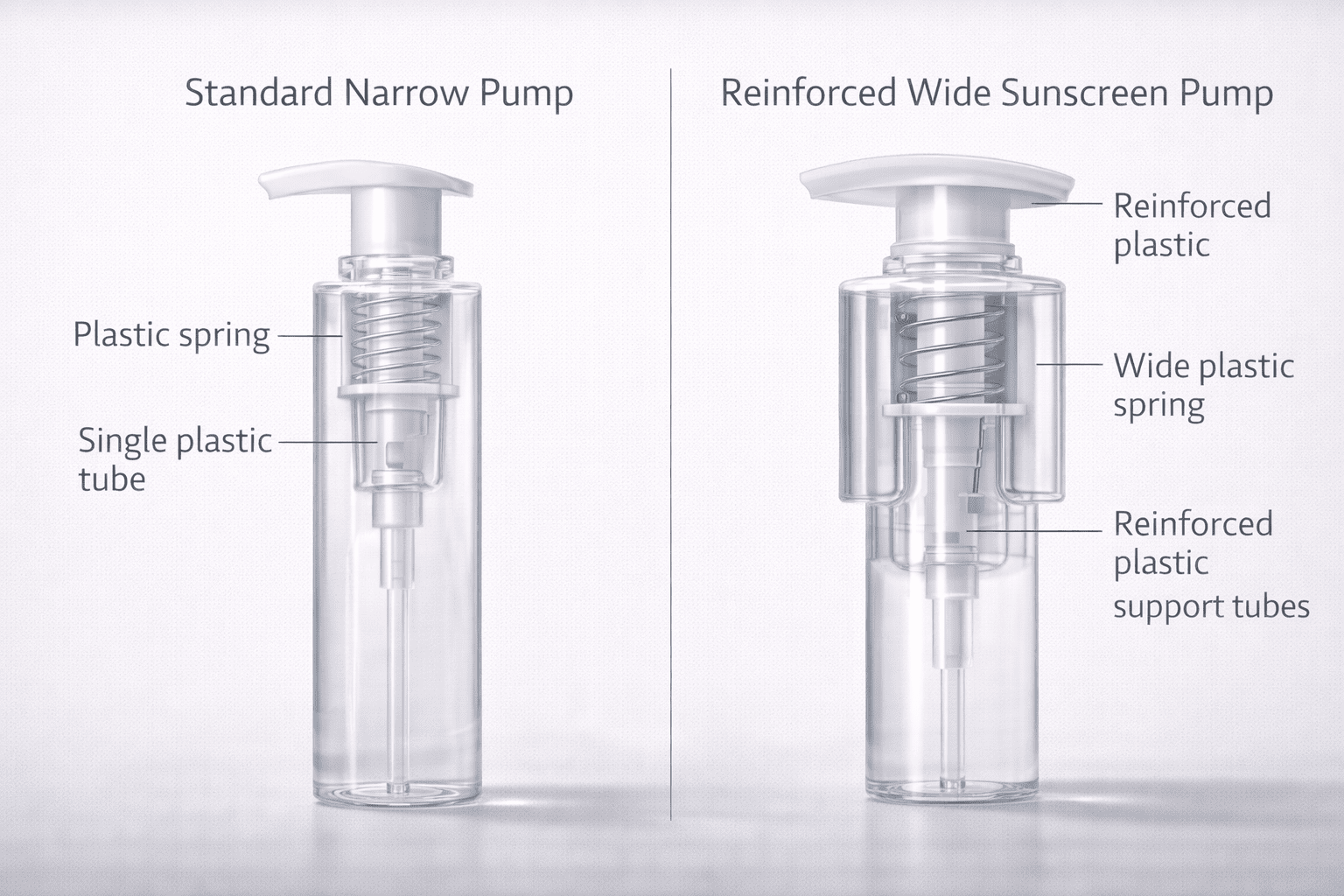

- Chemical Incompatibility: Many chemical UV filters are aggressive solvents. They can slowly degrade the plastics or metal springs inside a standard pump mechanism, causing it to become stiff or break down.

- Physical Clogging: Mineral sunscreens, like those with Zinc Oxide or Titanium Dioxide, contain tiny particles. If the pump's nozzle and internal channels are too narrow, these particles build up over time and create a blockage. The result is an uneven spray or a complete failure.

To prevent this, we match the pump to the formula. For a thick mineral lotion, we'd select a lotion pump with a wider actuator and a more powerful engine. For a chemical spray, we'd ensure all components are made from compatible materials like PP that resist degradation. We also validate the pump's performance over its entire expected lifecycle, not just on day one.

Is it normal for my sunscreen bottle to turn yellow?

You see your product on a store shelf, and the bottle has turned a sickly yellow color. It makes your brand look old and cheap, even though the sunscreen inside is perfectly fine.

No, it is not normal. The bottle is turning yellow because the plastic material is not compatible with the sunscreen formula or lacks sufficient UV resistance. This is a sign of material degradation.

This is a silent killer of brand perception. The problem is material incompatibility. Sunscreen ingredients, especially certain UV filters like Avobenzone, are notoriously reactive. When they are in contact with an incompatible plastic, they can cause chemical migration, leading to discoloration, brittleness, or loss of clarity. This doesn't just look bad; it can compromise the integrity of the packaging and potentially the product itself. The solution is rigorous material testing. We don't just choose a material based on cost or appearance. We conduct accelerated aging tests where we fill the proposed bottle with the client's actual formula and expose it to heat and UV light. This simulates months of shelf life in just a few weeks. Based on the results, we might recommend PETG for its clarity and good compatibility, or even a multi-layer bottle for ultimate protection.

How do you fix a bad sunscreen spray experience?

Customers complain that your sunscreen sprays in a messy stream, drips down their arm, or requires endless pumping. The application is so unpleasant that they won't buy it again, regardless of how good the formula is.

You fix it by optimizing the pump's output and spray angle. A high-output pump (0.25ml) is better for lotions, while a wider spray angle is needed for body mists to ensure even, non-drippy coverage.

The user experience of the spray is everything. No one wants a sunscreen that shoots out like a water gun. A poor application experience is purely a mechanical problem that can be easily solved with the right engineering. The key factors are Spray Output and Spray Pattern. For a product meant to cover a large area like the back or legs, you need a pump that delivers a good amount of product with a wide, conical spray pattern. An output of 0.18ml or 0.25ml is often ideal. This ensures sufficient coverage with each pump, preventing the user from having to spray dozens of times. For a facial sunscreen mist, the opposite is true—you'd want a very fine, low-output spray. The mistake many brands make is using a generic sprayer for all applications. We work with clients to define the target application, then select a pump and nozzle combination that creates the perfect mist for that specific purpose.

Conclusion

Sunscreen packaging demands a higher standard. Addressing these common failures by partnering with an experienced manufacturer protects your product, your brand's reputation, and ensures a great user experience every time.

Written by

Mike Lee

You may also be interested in:

Which Cap is Right for Your Spray Bottle: Overcap, Clip Lock, or Screw Cap?

You've spent months perfecting your formula and choosing the right spray pump. Now you need

Pump Doesn’t Work After 1–3 Months? The Real Reasons Spray Bottles Fail Over Time

You’ve launched a fantastic product with a fine mist sprayer, but after a few months,

Why Are Sunscreen Formulas So Tough on Packaging?

You've developed a brilliant sunscreen formula, but the packaging keeps failing. Bottles are turning yellow,

What Are the Best Sustainable Packaging Solutions for Sunscreen Brands?

You want to use sustainable packaging, but you're afraid it will fail. Choosing the wrong