Why Do Brands Prefer Airless Pump Bottles for Sunscreen Products?

November 18, 2025 • Mike Lee

You've invested heavily in a sophisticated sunscreen formula with sensitive active ingredients. But you worry that a standard bottle will expose it to air and contaminants, reducing its effectiveness before it even reaches the customer.

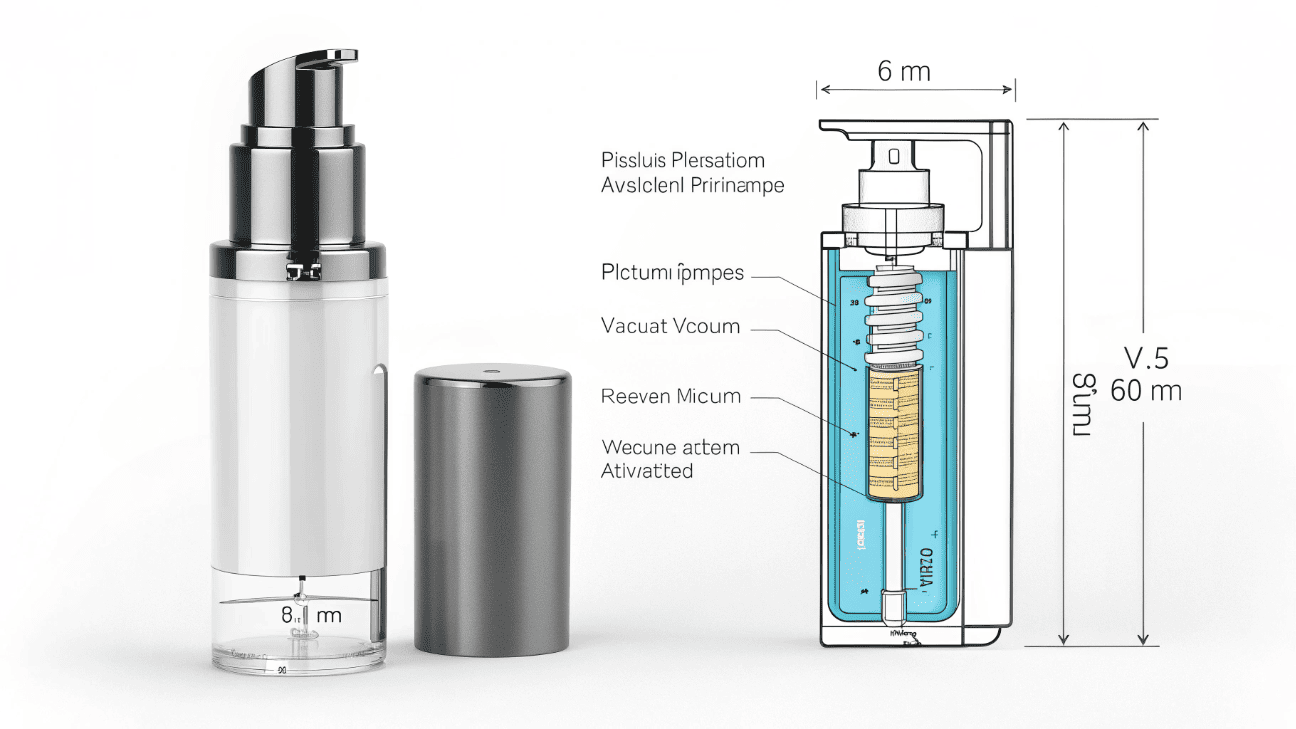

Brands prefer airless pump bottles because they create a vacuum that prevents air and bacteria from degrading the sunscreen formula. This preserves the stability of active ingredients, ensures hygienic application, and allows customers to use nearly 100% of the product.

Your understanding of the core benefits is exactly what drives this trend. I once worked with a brand that launched a high-end Vitamin C sunscreen. In traditional packaging, customers complained that the product near the top turned yellow after a few weeks. It was oxidation. The formula was failing because of air exposure. We transitioned them to an airless system for their next production run. The complaints stopped overnight. The bottle wasn't just a container; it was an essential part of the product's delivery system, guaranteeing the formula inside stayed potent and stable from the first pump to the last. This is the power of airless technology.

Why are airless cosmetic bottles so popular in skincare packaging?

You see airless bottles everywhere for serums and creams, and you wonder what's driving this universal appeal. Is it just a marketing trend, or is there a real, functional advantage you're missing?

Airless bottles are popular because they solve the three biggest problems of traditional packaging: they protect sensitive ingredients from oxidation, provide a clean and hygienic dose every time, and prevent product waste by ensuring a high evacuation rate.

The popularity of airless technology isn't a trend; it's a direct response to the demand for more effective and sophisticated skincare. As formulas become more advanced, with less reliance on traditional heavy preservatives, the packaging has to work harder to protect the product. An airless bottle is an active preservation system.

| Core Benefit | How Airless Technology Delivers |

|---|---|

| Formula Protection | As you press the pump, a piston or diaphragm at the bottom of the bottle rises, pushing the product up without letting any air in. This prevents the oxidation that can destroy antioxidants and active ingredients. |

| Hygienic Application | There is no dip tube that goes back into the bulk product, and the user's fingers never touch the formula inside. This drastically reduces the risk of bacterial or fungal contamination. |

| Reduced Product Waste | The piston system scrapes the walls of the bottle as it rises, ensuring that over 95% of the product is dispensed. Customers appreciate getting what they paid for, and it reflects well on the brand. |

Are Airless Bottles the Future of Eco-Friendly Skincare Packaging?

You want to make sustainable choices, but you see that airless bottles often look like complex, multi-part plastic items. This seems counter-intuitive to the "eco-friendly" message, leaving you confused.

Yes, airless bottles are a key part of eco-friendly packaging, but for a different reason. Their sustainability comes from reducing product waste and, most importantly, their suitability for innovative refillable systems, which dramatically cuts down on overall plastic use over time.

The eco-friendly story of airless packaging is more about its lifecycle than its initial material. While some airless bottles are recyclable (especially mono-material PP options), their biggest environmental impact comes from changing consumer behavior from "dispose" to "reuse."

4 Reasons Airless Drives Eco-Friendly Packaging:

- Reduces Product Waste: When 15-25% of a product is left in a traditional bottle, that's wasted formula and resources. Airless systems cut that waste to less than 5%, meaning less goes to landfill.

- Enables Refillable Models: This is the key. Brands can create a beautiful, durable outer airless bottle and sell a simple, lightweight inner cartridge as a refill. The consumer keeps the high-value pump and outer bottle and only replaces the small inner part.

- Encourages Mono-Material Design: We are now producing more airless bottles made entirely from PP (polypropylene). This makes the entire unit much easier for consumers to recycle compared to mixed-material packaging.

- Protects Natural Formulas: As brands move to "clean" formulas with fewer preservatives, airless packaging is essential. It protects these natural products without needing extra chemical stabilizers, which aligns with an eco-conscious brand ethos.

Why is a 50mL airless pump bottle an ideal choice?

You need to select a size for your new sunscreen launch and feel paralyzed by options. You need a standard, versatile size that works for pricing, marketing, and travel regulations.

The 50mL airless pump bottle is ideal because it hits the sweet spot for premium facial products. It's large enough to offer good value but small enough to be travel-friendly (under the 100mL/3.4oz limit), and it has become the consumer-recognized standard size for high-quality serums and lotions.

Choosing a package size is a strategic business decision, not just a logistical one. The 50mL size has become a benchmark in the beauty industry for several key reasons, making it a safe and effective choice for a product launch.

Strategic Advantages of the 50mL Size:

- Travel Compliance: It easily meets TSA and international regulations for carry-on luggage, making it perfect for customers on the go. This is a huge selling point for a travel-essential product like sunscreen.

- Perceived Value: For a facial sunscreen, 50mL is perceived as a generous, full-size product, justifying a premium price point. It feels more substantial than a 30mL bottle but less of a commitment than a 100mL bottle.

- Supply Chain Availability: Because 50mL is a very popular size, a wide variety of high-quality stock airless pump systems are readily available. This means more design options and often faster lead times from suppliers like us.

- Ergonomics: The size is comfortable to hold and operate with one hand, making for a pleasant daily user experience.

Conclusion

Brands choose airless bottles for sunscreen because they are not just containers; they are active systems that protect the formula, enhance user experience, and support modern, sustainable marketing strategies. It's the smartest choice.

Written by

Mike Lee

You may also be interested in:

Which Cap is Right for Your Spray Bottle: Overcap, Clip Lock, or Screw Cap?

You've spent months perfecting your formula and choosing the right spray pump. Now you need

Pump Doesn’t Work After 1–3 Months? The Real Reasons Spray Bottles Fail Over Time

You’ve launched a fantastic product with a fine mist sprayer, but after a few months,

Why Are Sunscreen Formulas So Tough on Packaging?

You've developed a brilliant sunscreen formula, but the packaging keeps failing. Bottles are turning yellow,

What Are the Best Sustainable Packaging Solutions for Sunscreen Brands?

You want to use sustainable packaging, but you're afraid it will fail. Choosing the wrong