You've developed a brilliant sunscreen formula, but the packaging keeps failing. Bottles are turning yellow, pumps are clogging, and you're dealing with customer complaints about leaks, undermining your brand's quality.

Sunscreen formulas are tough on packaging because they contain aggressive chemical solvents, abrasive mineral particles, and are used in high-heat, high-UV environments. These factors can cause plastic to degrade, discolor, or deform unless the packaging is specifically engineered for compatibility.

I'll always remember a client who came to us after a failed launch. They had used a standard, off-the-shelf PET bottle that looked beautiful. But their formula contained a high concentration of a common chemical UV filter. Within months, they had reports of the bottles feeling "soft" and some even warping. The formula was literally eating the plastic from the inside out. They learned a costly lesson that day: with sunscreen, the formula dictates the packaging. You can't just pick a pretty bottle; you have to pick the right bottle. It's a science, and it starts by understanding exactly what you're up against.

How do chemical UV filters degrade plastic packaging?

You chose a crystal-clear bottle to showcase your lightweight chemical sunscreen. Now, you're seeing reports that the bottle is becoming cloudy or brittle, making your premium product look cheap and old.

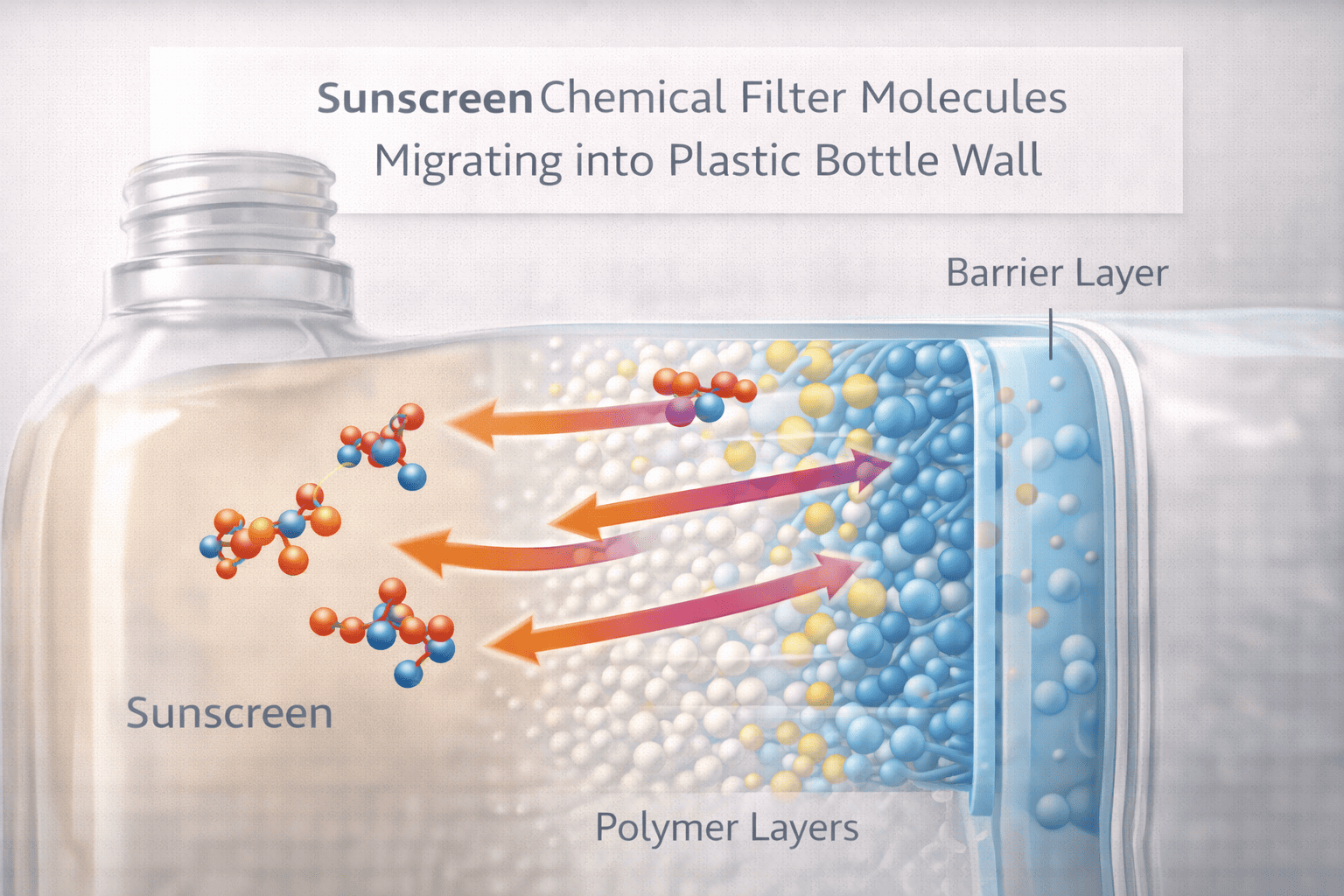

Many chemical UV filters, like Avobenzone and Oxybenzone, are powerful organic solvents. They can migrate into the molecular structure of incompatible plastics, causing them to swell, lose clarity, and become brittle over time.

Think of it like this: "like dissolves like." Chemical UV filters are complex organic molecules, and so are plastics like PET and PP. Given the chance, the filter molecules will try to embed themselves into the plastic. This process, called chemical migration, is the number one cause of packaging failure for chemical sunscreens. It doesn't just look bad; it can compromise the structural integrity of the bottle, leading to stress cracks and potential leaks. The solution is to choose a material that is chemically resistant to your specific formula. We don't guess. We perform rigorous immersion testing, where we submerge samples of different plastics in the client's actual formula for weeks under accelerated conditions to see which one holds up the best.

Material Compatibility Guide

| Plastic Type | Common Reaction to Chemical Filters | Best Solution |

|---|---|---|

| Standard PET | Can become cloudy, soft, or yellow. | Use a higher-grade PET or conduct thorough compatibility testing. |

| Polypropylene (PP) | Generally more resistant, but can still be affected by certain solvents. | A solid choice, especially for caps and pumps, but must be tested. |

| PETG | Often shows superior chemical resistance and clarity. | An excellent, though more premium, choice for many formulas. |

Why do mineral sunscreens clog pumps and damage bottles?

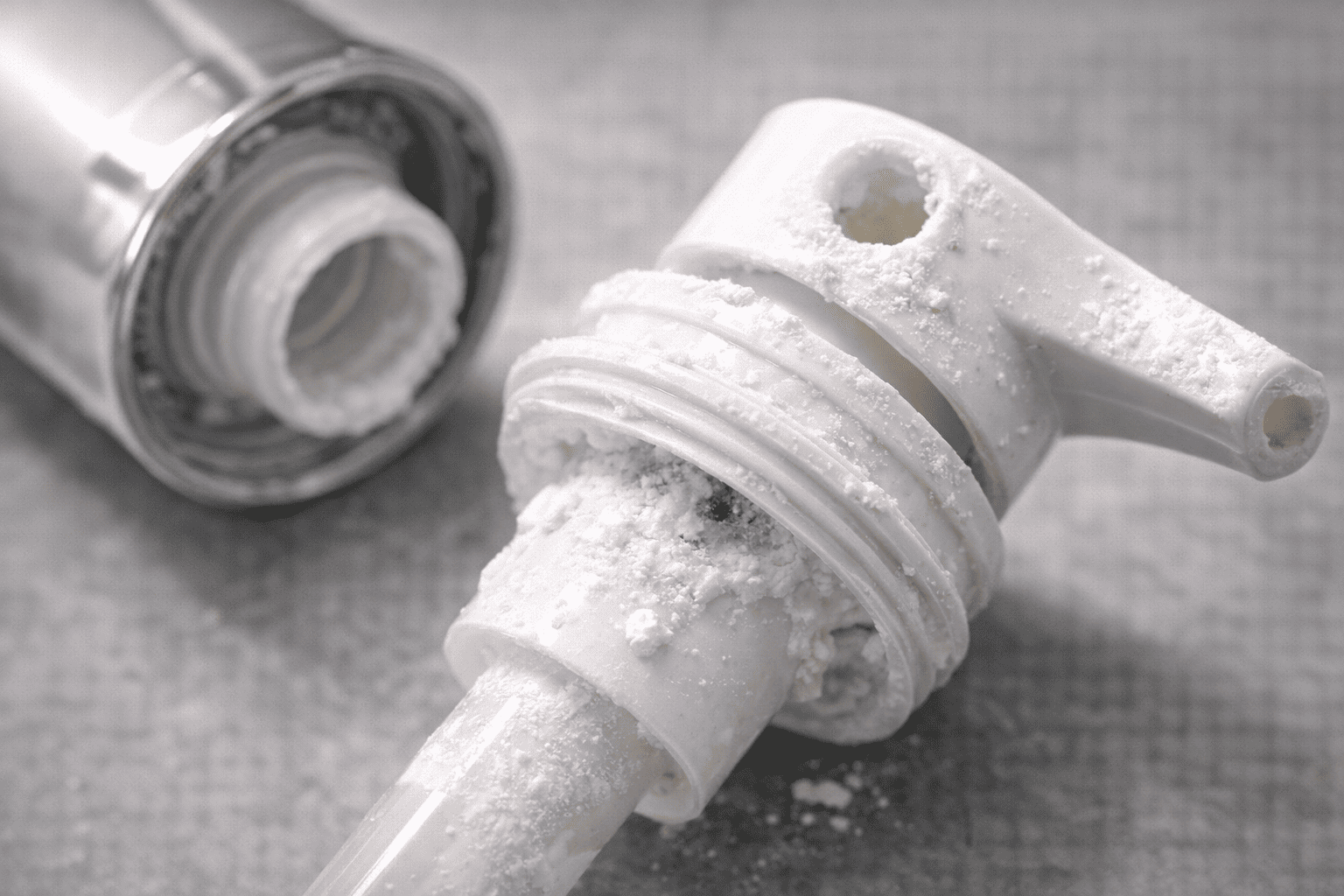

Your mineral sunscreen is a fantastic, thick formula, but customers are complaining the pump stops working after a few uses. You might also notice fine scratches on the inside of clear bottles.

Mineral sunscreens contain fine, hard particles like Zinc Oxide and Titanium Dioxide. These abrasive particles can physically wear down pump mechanisms and scratch bottle interiors, and their high viscosity can easily clog standard pump nozzles.

Unlike chemical sunscreens that cause chemical damage, mineral sunscreens cause physical damage. The problem is twofold: abrasion and viscosity. The Zinc Oxide and Titanium Dioxide particles, while microscopic, are essentially very fine rocks. As the product is pumped, these hard particles scrape against the internal components of the pump—the spring, the piston, the seals. Over time, this abrasion causes the parts to wear down and fail. On the other hand, the formula's thickness, or viscosity, presents its own challenge. A standard mist sprayer is designed for watery liquids. Trying to force a thick mineral cream through it is like trying to push honey through a tiny straw—it will clog. The solution is to use a pump specifically designed for high-viscosity lotions. These pumps have wider internal channels, more powerful engines, and are built from more durable materials to withstand the abrasion.

How does heat and sunlight worsen packaging failures?

Your sunscreen packaging passed initial tests, but it's failing in the real world. Customers leave it in a hot car or a beach bag, and suddenly the bottles are leaking, warping, or the sprayers stop working.

Heat and UV radiation act as catalysts, dramatically accelerating the chemical reactions and physical stresses on packaging. Heat can lower a plastic's resistance, making it softer and more vulnerable to chemical attack, while UV light can degrade the plastic itself.

This is the final piece of the puzzle and your key insight is spot on. Sunscreen is not used in a climate-controlled bathroom; it's used in the harshest environments imaginable. Heat is a major enemy. It can cause the air inside the bottle to expand, putting immense pressure on the seals and potentially forcing a leak. It also speeds up any chemical reactions between the formula and the plastic, turning a slow degradation into a rapid failure. Direct sunlight adds another layer of attack. The UV radiation that your product is designed to block can also break down the polymer chains in the packaging itself, making it brittle and prone to cracking. This is why our testing protocol simulates these worst-case scenarios. We have heat-aging ovens and UV stability chambers to ensure the packaging we design will survive not just on the shelf, but in the real world where your customers use it.

Conclusion

Sunscreen formulas are inherently aggressive. By understanding the specific chemical and physical challenges they pose, and by testing for real-world conditions like heat and sun, we can engineer packaging that protects your formula and your brand.

Written by

Mike Lee

You may also be interested in:

Which Cap is Right for Your Spray Bottle: Overcap, Clip Lock, or Screw Cap?

You've spent months perfecting your formula and choosing the right spray pump. Now you need

Pump Doesn’t Work After 1–3 Months? The Real Reasons Spray Bottles Fail Over Time

You’ve launched a fantastic product with a fine mist sprayer, but after a few months,

What Are the Best Sustainable Packaging Solutions for Sunscreen Brands?

You want to use sustainable packaging, but you're afraid it will fail. Choosing the wrong

Is Your Eco-Friendly Sunscreen Packaging Actually Green, or Just Greenwashing?

Your brand wants sustainable sunscreen packaging. But using unverified eco-materials can lead to leaks and