What Truly Makes a High-Quality Spray Bottle? A Complete Buyer’s Guide

December 19, 2025 • Mike Lee

You need to source spray bottles for your product line, but you're overwhelmed. Two bottles can look identical online, yet one costs half the price of the other, leaving you to wonder what you're really paying for.

A high-quality spray bottle is defined by four things: the purity of its raw materials, the precision of its pump engine, its physical gram weight, and the reliability of its manufacturer (proven by quality control systems like ISO 9001).

I learned this lesson the hard way early in my career. We received two samples from two different suppliers. On paper, they were the same—same size, same shape, same plastic type. But when I held them, the difference was immediate. One felt flimsy, you could squeeze the walls easily, and the pump action was scratchy. The other felt solid, substantial, and the pump was smooth as silk. The second bottle had a higher "gram weight"—it was made with more material—and used a better pump. It cost a few cents more, but it felt ten times more premium. That's when I realized quality isn't just about what a bottle looks like; it's about what it's made of.

What key features define a high-quality spray bottle?

You're comparing supplier spec sheets and everything looks similar. You need to know the specific, measurable features that separate a premium, reliable bottle from a cheap one that will fail and damage your brand's reputation.

The two most critical features to look for are the material purity (insisting on 100% virgin raw materials) and the bottle's gram weight. A heavier bottle with pure materials is almost always more durable and feels more luxurious.

Let's break this down, because this is where many brands make costly mistakes. Low-cost suppliers often cut corners by mixing in cheap filler or uncertified recycled materials. This can lead to inconsistencies, chemical leaching, and bottle failure. A higher gram weight means thicker walls, which provides better durability and a more substantial feel in the customer's hand. It's a direct indicator of quality you can feel. When you source, don't just ask for a price. Ask for a detailed spec sheet and, if possible, get samples to compare.

| Key Feature | Why It Is Critical for Quality | What You Should Demand |

|---|---|---|

| Material Purity | Prevents contamination, ensures structural integrity, and guarantees consistency across a production run of millions of units. | A guarantee of 100% virgin PET, PP, or PE from a certified source. Ask for material data sheets. |

| Gram Weight | Directly relates to wall thickness, durability, and the premium feel of the product. Heavier bottles resist cracking and deformation. | A specific gram weight for your bottle (e.g., 25g for a 100ml bottle) with a very low tolerance for variation. |

What are the essential components that must be perfect on each spray bottle?

You might be focusing on the bottle itself, but you're forgetting that the bottle is just a container. The part the customer interacts with every single time is the pump, and a failure here makes the entire product useless.

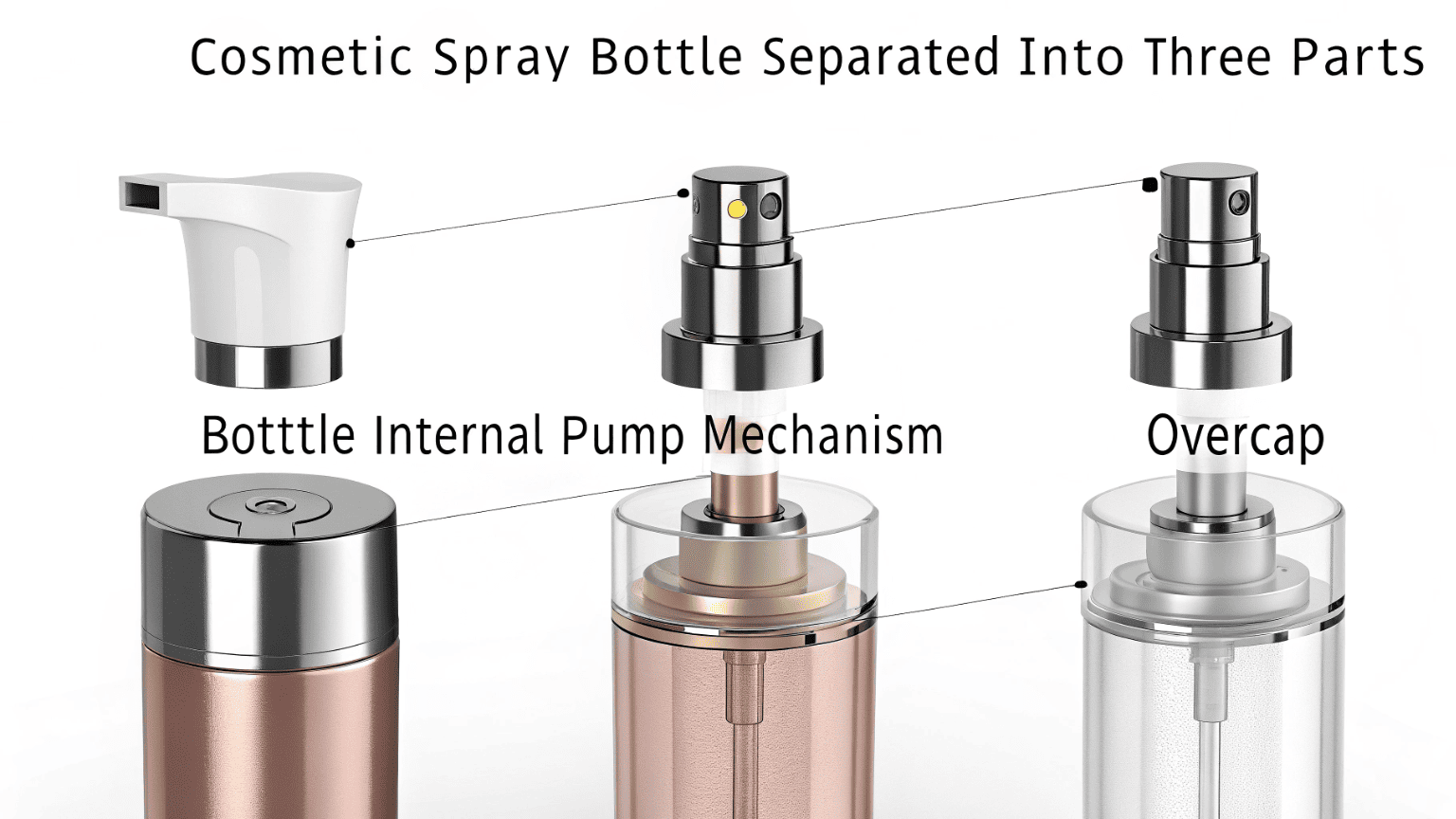

Every high-quality spray bottle consists of three essential components working in harmony: a durable bottle body, a precision-engineered pump engine, and a secure, well-fitting overcap to prevent leaks and contamination.

The pump is the heart of the product. It's also the most complex part and the easiest place for manufacturers to cut costs. A cheap pump might use a weak metal spring that rusts, a low-grade rubber gasket that swells and fails, or a poorly molded piston that delivers an inconsistent spray. A high-quality pump engine, however, is a work of precision engineering.

- The Pump Engine: This is not a single part. It's an assembly of a piston, a stem, a gasket, a spring, and a ball valve. For a fine-mist sprayer, the quality of these internal parts determines whether you get a gentle cloud or a wet squirt.

- The Bottle Body: As we discussed, this needs to be made of pure, high-grade material with a consistent wall thickness.

- The Overcap: This isn't just for show. It provides a final seal against leakage and protects the nozzle from dirt and debris. It should click on securely and not pop off easily.

How does a spray bottle actually work (the Bernoulli principle)?

It seems like simple magic: you press down, and liquid sprays out. But you know there's science at work, and understanding it can help you appreciate why the quality of the internal components is so important.

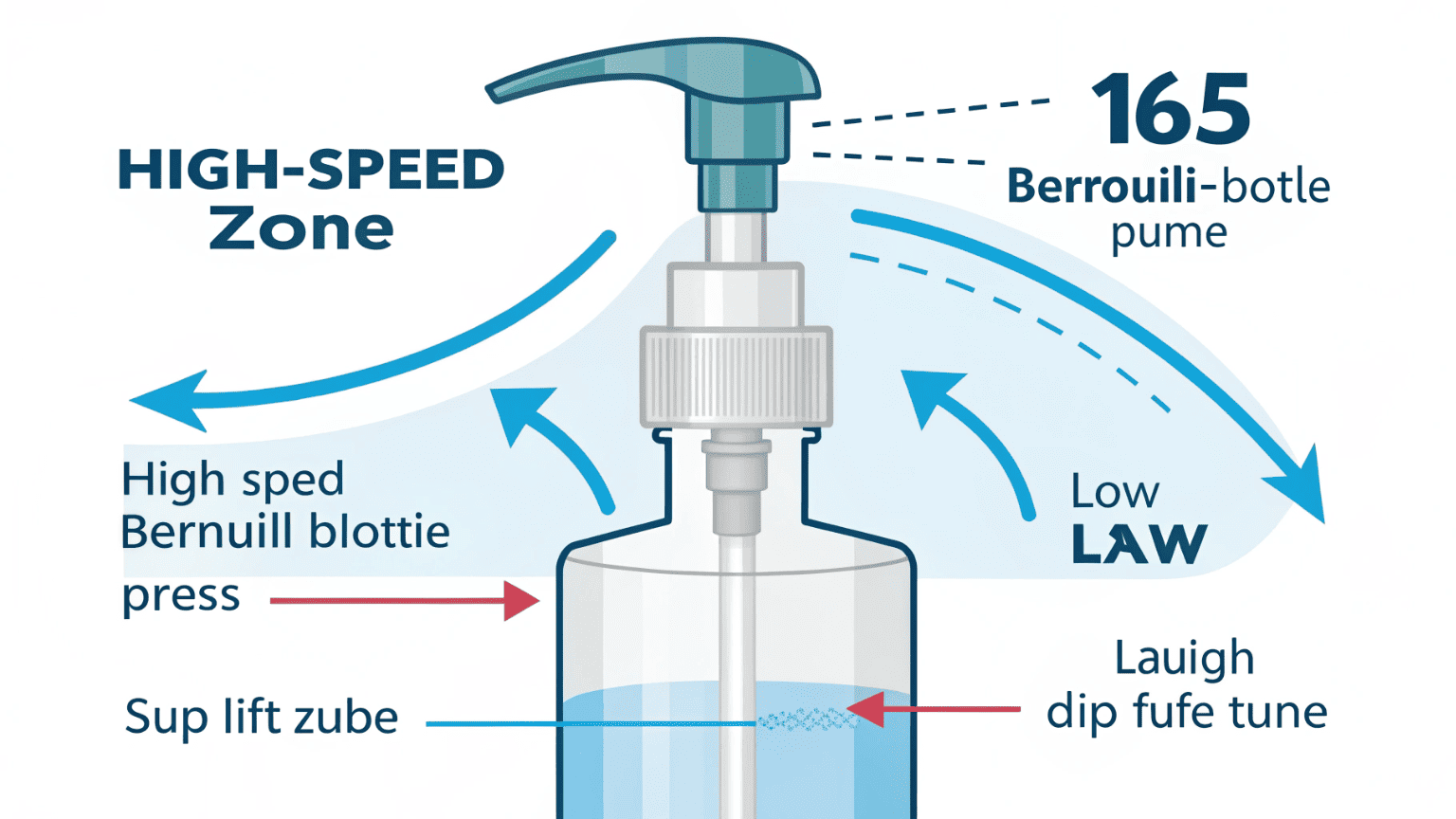

A spray bottle works using the Bernoulli principle. When you press the pump, it shoots a jet of high-speed air across the top of a dip tube. This fast-moving air creates a low-pressure zone, which sucks the liquid up the tube and into the air stream, where it is atomized into a fine spray.

Think about blowing over the top of a piece of paper. The paper lifts up, right? That's Bernoulli's principle in action. Your breath is the fast-moving air, and the lower pressure above the paper lifts it. A spray pump does the exact same thing inside its tiny chamber.

- The Plunger: When you press down, you force air out of a small cylinder at high speed.

- The Dip Tube: This high-speed air rushes over the top opening of the dip tube that goes down into the liquid.

- The Pressure Drop: According to Bernoulli, this fast-moving air has lower pressure than the still air inside the bottle.

- The Suction: The higher pressure inside the bottle then pushes the liquid up the dip tube to fill the low-pressure void.

- Atomization: As the liquid exits the tube, it mixes with the high-speed air stream and is broken into tiny droplets, forming the spray.

This is why a well-machined pump is so critical. Any leaks or imperfections will prevent the creation of a strong low-pressure zone, resulting in a weak or failed spray.

Conclusion

A high-quality spray bottle is not an accident. It is the result of using pure materials, precise engineering based on scientific principles, and a manufacturer who prioritizes quality control over cutting corners.

Written by

Mike Lee

You may also be interested in:

Why Are 50ml Spray Bottles the Best-Selling Size?

You're developing a new product and you're stuck on a critical decision: the bottle size.

Which Cap is Right for Your Spray Bottle: Overcap, Clip Lock, or Screw Cap?

You've spent months perfecting your formula and choosing the right spray pump. Now you need

Pump Doesn’t Work After 1–3 Months? The Real Reasons Spray Bottles Fail Over Time

You’ve launched a fantastic product with a fine mist sprayer, but after a few months,

Why Are Sunscreen Formulas So Tough on Packaging?

You've developed a brilliant sunscreen formula, but the packaging keeps failing. Bottles are turning yellow,