What Are the Best Sustainable Packaging Solutions for Sunscreen Brands?

January 14, 2026 • Mike Lee

You want to use sustainable packaging, but you're afraid it will fail. Choosing the wrong eco-friendly material for your sunscreen can lead to leaks and degradation, harming your brand and creating more waste.

The best solutions are PCR (Post-Consumer Recycled) plastic at validated percentages (30-50%) and well-designed refillable systems. These options balance sustainability with the chemical resistance and durability required to safely package aggressive sunscreen formulas.

A few years ago, a brand owner, very much like Shubihika, came to us with a vision. She wanted to create the most luxurious and sustainable sunscreen on the market. Her idea was to use a beautiful glass bottle that could be refilled. It was a brilliant concept, but we knew sunscreen formulas can be tricky. We worked with her to select a type of glass that wouldn't react with her formula and designed a simple, hygienic refill pouch system. The final product was a huge success. It proved to me that sustainability and luxury aren't mutually exclusive; they just require thoughtful engineering from the very beginning.

You associate eco-friendly packaging with flimsy or unrefined materials. You're worried that shifting to sustainable options will cheapen the premium feel of your sunscreen brand.

A premium feel comes from smart design, weight, and finish—not just the material's origin. Using heavy-wall PETG with PCR content, sleek aluminum, or elegant glass can deliver a high-end experience while being sustainable.

This is a common fear, but it's based on an outdated view of sustainable materials. Today, you can achieve a premium feel without compromise. It’s all about the execution. For example, we can use PETG plastic—known for its glass-like clarity—with a 30% PCR content. By designing it with a thicker, heavier wall, it feels substantial and valuable in the hand. The finish is also key. A soft-touch texture, a high-gloss UV coating, or crisp silk-screen printing can elevate any material. Aluminum is another fantastic option; it's infinitely recyclable and has a natural coolness and metallic sheen that consumers associate with quality. The key is to shift the focus from "Is it virgin plastic?" to "Does it feel well-made?"

Premium Sustainable Options

| Material | Why It Feels Premium | Sustainability Angle | Best For |

|---|---|---|---|

| Heavy-Wall PETG + PCR | Glass-like clarity, substantial weight, excellent decoration capabilities. | Incorporates recycled plastic, reducing virgin material use. | High-end facial sunscreens, lotions. |

| Aluminum | Cool to the touch, seamless, modern aesthetic, lightweight yet strong. | Infinitely recyclable with high recycling rates. | Body sprays, mists, minimalist brands. |

| Glass + Refill Pouch | The ultimate in luxury, heavy and cool, completely inert. | The primary container is reused many times, with a lightweight pouch for refills. | Luxury facial sunscreens, at-home use products. |

What materials are best for sourcing sustainable sunscreen bottles?

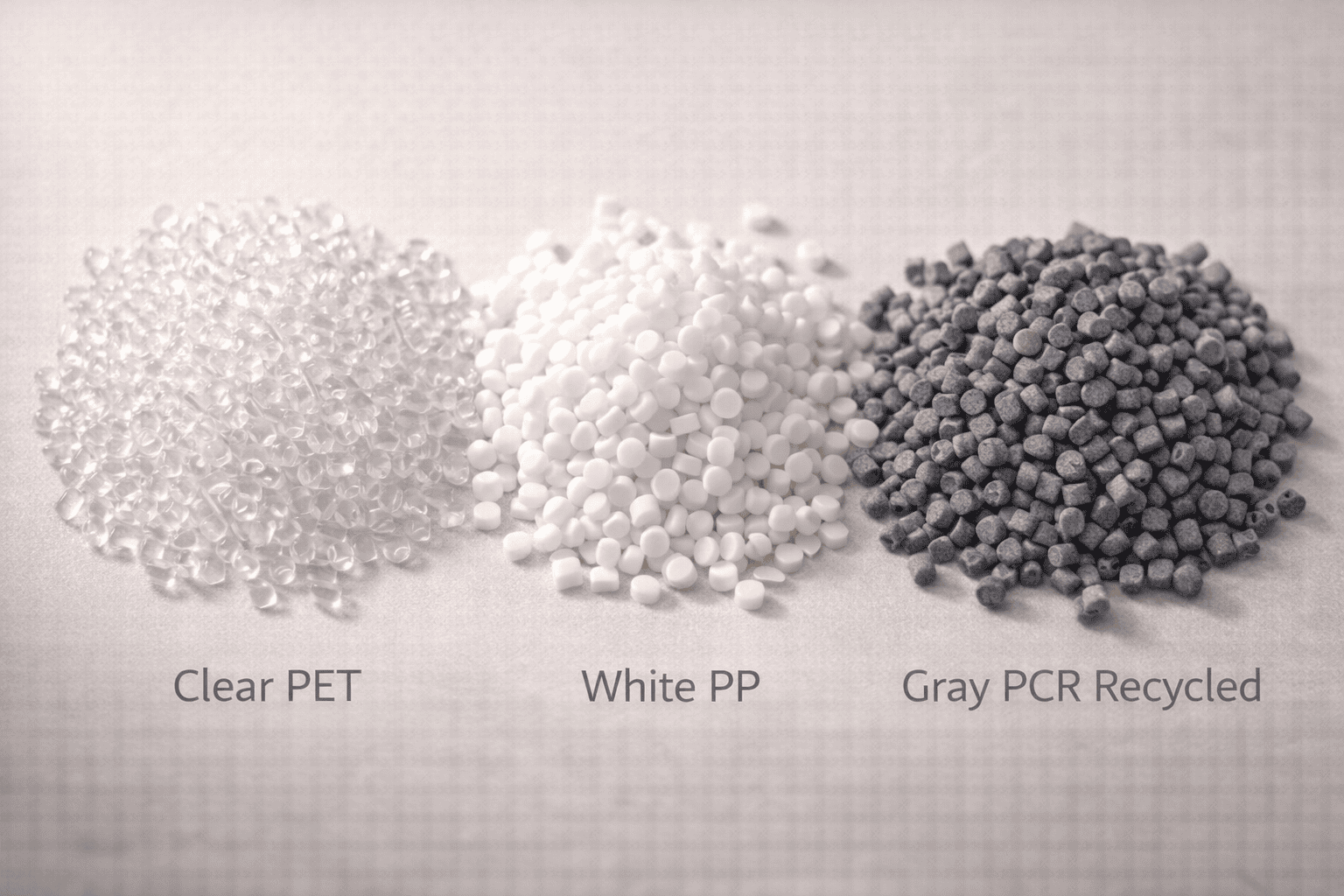

You're ready to source sustainable bottles, but the alphabet soup of plastics (PET, PP, PCR) is confusing. You don't know which material is safe for your formula and truly sustainable.

For sunscreen, your best options are PET and PP with certified PCR content. PET offers excellent clarity and chemical resistance, while PP is extremely durable and a great choice for airless pumps. Both can safely incorporate recycled material.

Choosing the right material is a critical technical decision. It's a balance between chemical compatibility, durability, and sustainability. For sunscreen, not all plastics are created equal. We primarily focus on two reliable options when incorporating recycled content: PET-PCR and PP-PCR. PET (Polyethylene Terephthalate) is the same plastic used for soda bottles. It has great clarity and provides a good barrier against many sunscreen chemicals. Incorporating PET-PCR is a well-established process. PP (Polypropylene) is an opaque, extremely robust plastic. It's very tough and has excellent resistance to heat and chemicals, making it ideal for the complex mechanisms in airless pumps. The key is using a validated percentage of PCR. We typically recommend starting at 30% and conducting rigorous compatibility testing with your specific formula. This ensures you get a real environmental benefit without risking the bottle's integrity.

How do refillable sunscreen bottles actually work?

You love the idea of a refillable system, but you can't picture how it works. You worry it might be messy, unhygienic, or too complicated for your customers to use correctly.

A good refillable system uses a durable primary bottle and a simple, lightweight refill unit (like a pouch or pod). The customer keeps the premium outer bottle and replaces the inner component, ensuring a clean, easy, and hygienic transfer every time.

The success of a refillable model hinges entirely on user experience. If it's complicated, it will fail. That's why the best systems are designed for simplicity. Imagine your beautiful, heavy-walled primary sunscreen bottle. The magic is that the pump and the inner container that holds the sunscreen are a single, sealed unit. When the product is empty, the customer doesn't pour anything. They simply unscrew the top, pull out the empty inner "cartridge," and drop in a new one. The refill cartridge is a simple, lightweight, and fully sealed unit that is less expensive to produce and ship, and it uses significantly less plastic than a whole new bottle. This system is brilliant because it's clean, foolproof, and preserves the integrity of the formula. For brands, it also creates a recurring revenue stream and locks in customer loyalty, as they will return to buy your specific refill.

Conclusion

Sustainable sunscreen packaging is no longer a dream. By choosing validated PCR materials or designing user-friendly refillable systems, you can create a product that is responsible, reliable, and reinforces your brand's premium quality.

Written by

Mike Lee

You may also be interested in:

Pump Doesn’t Work After 1–3 Months? The Real Reasons Spray Bottles Fail Over Time

You’ve launched a fantastic product with a fine mist sprayer, but after a few months,

Why Are Sunscreen Formulas So Tough on Packaging?

You've developed a brilliant sunscreen formula, but the packaging keeps failing. Bottles are turning yellow,

Is Your Eco-Friendly Sunscreen Packaging Actually Green, or Just Greenwashing?

Your brand wants sustainable sunscreen packaging. But using unverified eco-materials can lead to leaks and

Why Does Sunscreen Packaging Fail So Often?

Your sunscreen leaks and pumps clog, leading to customer complaints and lost sales. These costly