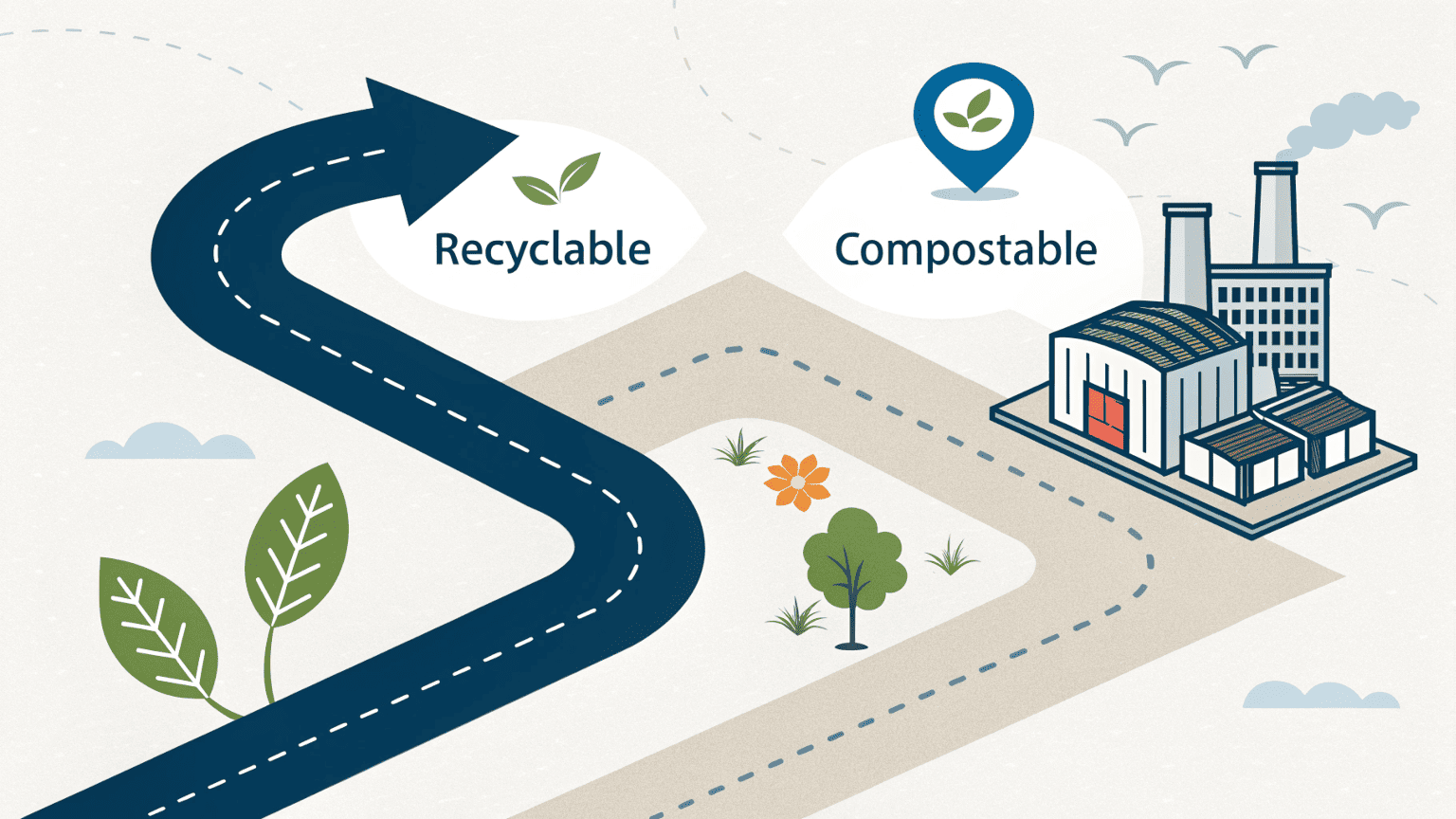

Recyclable vs Compostable: Which Is Right for Your Brand?

October 22, 2025 • Mike Lee

Confused by eco-friendly packaging terms? You want to make the right choice for your brand but fear the hidden costs and practical pitfalls of compostable materials.

For most cosmetic brands today, recyclable packaging is the more practical and globally effective choice. It leverages existing infrastructure and is more cost-effective, offering a clearer path to sustainability than the current compostable options.

Your insight about cost and infrastructure is the exact conversation we have with our partners every day. A few years ago, a promising brand from Southeast Asia came to us, excited about launching their line in "fully compostable" packaging. It's a beautiful idea. But when we analyzed their target markets, we found almost zero access to the industrial composting facilities needed to break down the material. We had to be honest with them. Their expensive "eco" packaging would have just ended up in a landfill. We helped them switch to a 100% PCR PET bottle—a recyclable solution that their customers could actually dispose of correctly. It was a better choice for the planet and their budget.

Which is better, compostable or recyclable?

You're trying to choose the most responsible option, but it feels like a trade-off. You want what's best for the planet, but also what's feasible for your business and your customers.

Recyclable is generally better because it fits into existing, widespread waste management systems. Compostable is only better when a product is guaranteed to end up in a specialized industrial composting facility.

The "better" choice depends entirely on the real-world journey your package will take after your customer is done with it. The ideal solution in a lab isn't always the ideal solution in the market. A side-by-side comparison makes the practical differences clear.

| Feature | Recyclable Packaging (e.g., PET, PP) | Compostable Packaging (e.g., PLA) |

|---|---|---|

| End-of-Life Goal | To be collected, melted down, and remade into new products (a circular process). | To be broken down by microorganisms into organic matter (a linear process). |

| Required Infrastructure | Widely available curbside recycling programs and material recovery facilities (MRFs) in most countries. | Requires specialized industrial composting facilities with high heat and specific microbes. Very rare in most regions. |

| Material Cost | More cost-effective. PCR (recycled) options are competitively priced. This aligns with your insight on cost, especially for brands in developing markets. | Significantly more expensive due to complex manufacturing and raw material sourcing (like corn starch). |

| Consumer Action | Simple for the consumer: rinse the container and place it in the recycling bin. | Complex for the consumer: they must identify it's compostable and have access to a specific composting bin (not the recycling or trash bin). |

For a global brand, the choice is clear. The recycling infrastructure is already there. The compostable one is not.

Does commercially compostable mean recyclable?

You see a package labeled "commercially compostable" and assume it's an all-around eco-friendly choice. You might even think it can be thrown in the recycling bin if composting isn't available.

No. "Commercially compostable" absolutely does not mean recyclable. In fact, compostable materials like PLA are a major contaminant in the plastic recycling stream and can ruin entire batches of recycled material.

This is the single most critical point of confusion for brands and consumers. Placing compostable packaging in a recycling bin does more harm than good.

1. The Problem of Material Contamination

Recycling works by sorting plastics into different types (PET, HDPE, PP), then melting them down. Each plastic type has a different melting point and chemical makeup.

- Compostable PLA: Bioplastics like PLA are designed to break down. When they get mixed with PET and melted down, they don't bond properly. Instead, they create structural weaknesses and impurities in the new recycled material, making it brittle and unusable.

- The Result: A single PLA container can force a recycling facility to discard an entire bale of valuable PET material, sending it all to the landfill.

2. Understanding the Labels

- Recyclable: This means the material can be processed by standard recycling facilities. Look for the familiar chasing arrows symbol with a number (e.g., #1 for PET, #5 for PP).

- Home Compostable: This means the item can break down in a backyard compost pile. This is rare for cosmetic packaging due to the need for barrier properties.

- Commercially/Industrially Compostable: This means the item will only break down under the high-temperature, high-pressure conditions of a dedicated industrial facility. It will not break down in a landfill or a home compost pile.

What are the disadvantages of compostable packaging?

You are drawn to the idea of a package that can "return to the earth." But you suspect there are downsides that aren't being talked about, especially when it comes to cost and real-world impact.

The primary disadvantages are high material costs, a near-total lack of consumer access to industrial composting facilities, and the high risk of the packaging simply ending up in a landfill, where it may do more harm than good.

Your insights about cost and requirements are spot on. For cosmetic packaging, the disadvantages of compostable materials currently outweigh the benefits for almost every brand.

1. The Infrastructure Desert

The biggest issue is practical. Fewer than 200 industrial-scale composting facilities exist in the entire United States, for example. The numbers are even lower in most other countries, especially in the developing world. If your customer doesn't have a special bin and a municipal service that takes it to one of these rare facilities, your compostable package is just trash.

2. Prohibitive Costs

As you noted, the materials are more expensive. PLA and other bioplastics can cost significantly more than their petroleum-based counterparts like PET or PP. This cost has to be passed on to the consumer or absorbed by the brand, making it a difficult choice for any company that needs to remain competitive. For our partners in India, Africa, and South America, this cost makes compostable packaging a non-starter.

3. The Landfill Problem

When a compostable package ends up in a landfill (which is its most likely fate), it is deprived of the oxygen it needs to biodegrade properly. Instead, it breaks down anaerobically and can release methane, a greenhouse gas that is far more potent than carbon dioxide. A stable, inert, recyclable plastic that is landfilled is arguably better than a compostable one that is landfilled.

Conclusion

For today's global cosmetic market, choosing recyclable packaging is the most responsible, cost-effective, and impactful decision. It utilizes a system that works, reduces waste, and supports a truly circular economy.

Written by

Mike Lee

You may also be interested in:

Why Are 50ml Spray Bottles the Best-Selling Size?

You're developing a new product and you're stuck on a critical decision: the bottle size.

Which Cap is Right for Your Spray Bottle: Overcap, Clip Lock, or Screw Cap?

You've spent months perfecting your formula and choosing the right spray pump. Now you need

Pump Doesn’t Work After 1–3 Months? The Real Reasons Spray Bottles Fail Over Time

You’ve launched a fantastic product with a fine mist sprayer, but after a few months,

Why Are Sunscreen Formulas So Tough on Packaging?

You've developed a brilliant sunscreen formula, but the packaging keeps failing. Bottles are turning yellow,