Pump Doesn’t Work After 1–3 Months? The Real Reasons Spray Bottles Fail Over Time

January 29, 2026 • Mike Lee

You’ve launched a fantastic product with a fine mist sprayer, but after a few months, you get the dreaded customer emails. The pump is stuck, it's sputtering, or it has stopped working entirely, turning a luxury experience into a frustrating one.

Spray bottles fail over time due to two primary reasons: internal mechanical failure of the pump's engine (like a fatigued spring or worn-out seal) or clogging caused by the formula itself, especially if it contains particles or has high viscosity.

I'll never forget a brand owner who came to us in a panic. They had launched a premium botanical facial mist. The product was amazing, but the sprayer was a disaster. It worked beautifully for the first month, and then a wave of complaints came in. We took apart one of the failed pumps and looked at it under a microscope. The problem was twofold: the metal spring inside was already showing signs of corrosion from the formula, and tiny plant fibers from their unfiltered botanical extract were clogging the nozzle. They had a great product let down by a pump that wasn't suited for it. It was a classic case of the pump and the formula not being properly matched.

Why do spray bottle pumps stop working?

Your product works perfectly when it leaves the factory. You test a hundred units and they're all fine. But after weeks of daily use, the pump mechanism just gives up and stops moving.

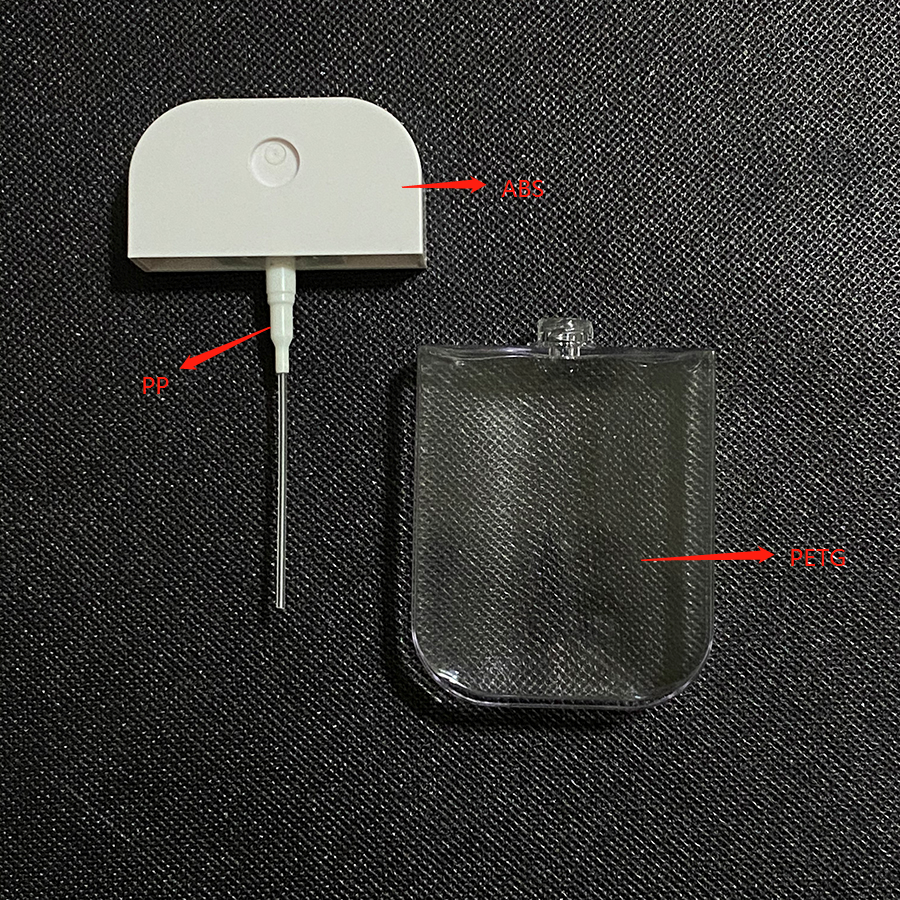

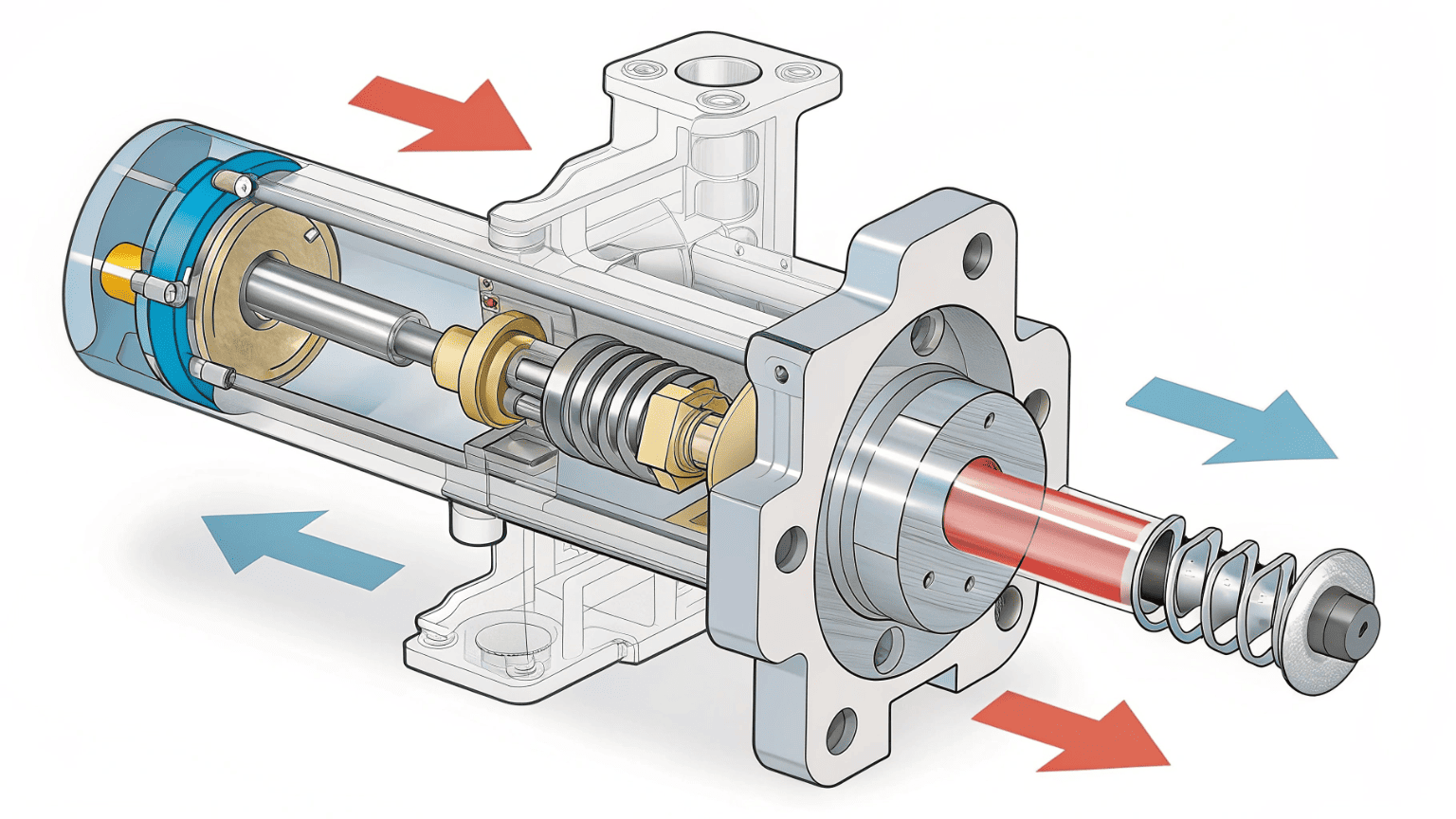

The pump's internal "engine"—made of a spring, a piston, and several gaskets—can mechanically fail. The spring can lose its tension from repeated use, or the piston's seal can wear out, preventing it from creating the vacuum needed to draw liquid up.

Think of a spray pump as a tiny, precision engine that has to perform flawlessly thousands of times. Every time you press down, you're compressing a small metal spring and pushing a piston. When you release, the spring pushes the piston back up, creating a vacuum in the chamber. This vacuum sucks the liquid up from the bottle through the dip tube. If any part of this engine fails, the whole system breaks. The most common point of failure is the spring. A low-quality spring made from inferior metal will lose its "memory" or elasticity after a few hundred pumps. It won't push the piston back up with enough force, so no vacuum is created. Another issue is the gasket or seal around the piston. If it's made from a material that isn't chemically resistant to your formula, it can swell or degrade, losing its tight seal. That's why we obsess over these tiny details, using high-grade stainless steel (like SUS 304) for our springs and conducting rigorous life-cycle tests where a machine pumps the sprayer thousands of times to ensure it outlasts the product inside.

Pump Component Quality Comparison

| Component | Low-Quality Version | High-Quality Rland Standard |

|---|---|---|

| Spring | Standard steel; prone to rust and fatigue. | SUS 304 Stainless Steel; rust-resistant, maintains tension. |

| Piston Seal | Standard rubber; can swell or degrade. | Chemically-resistant polymers; matched to the formula. |

| Glass Ball | Inconsistent size; can allow backflow. | Precision-milled; ensures a perfect one-way valve seal. |

Why do spray bottles fail so often by clogging?

Your spray bottle doesn't seem broken—the pump moves fine—but nothing comes out, or it just sputters a weak stream. You've tried running it under hot water, but the clog keeps coming back.

Clogging is the most common failure and is caused by the formula itself. Viscous liquids are too thick for the fine channels, and any solid particles—like glitter, minerals, or botanical fibers—can easily block the tiny nozzle orifice.

This directly addresses your core insight and it's the problem we see most often. The magic of a fine mist comes from forcing liquid through an extremely small opening, or orifice. This orifice can be smaller than the width of a human hair. While this creates a beautiful cloud-like spray with watery liquids, it's a nightmare for the wrong type of formula. A slightly thicker lotion or serum simply can't get through; the viscosity is too high. It's like trying to force honey through a coffee straw. The other big enemy is solid particles. This includes pigments in liquid makeup, shimmer particles in body sprays, or zinc oxide in a liquid sunscreen. Even natural formulas can contain microscopic plant fibers that clump together and cause a blockage. The solution isn't just a better pump; it's the right pump. For more viscous formulas, we recommend pumps with larger engines and wider orifices. For formulas with particles, we might recommend a pump with a special "anti-clogging" nozzle design. It’s all about matching the pump’s specifications to the formula’s properties.

What external factors cause a pump sprayer to stop working?

The pump and formula were perfectly matched and tested. Yet, after months in a customer's bathroom or travel bag, it still fails. What else could possibly go wrong?

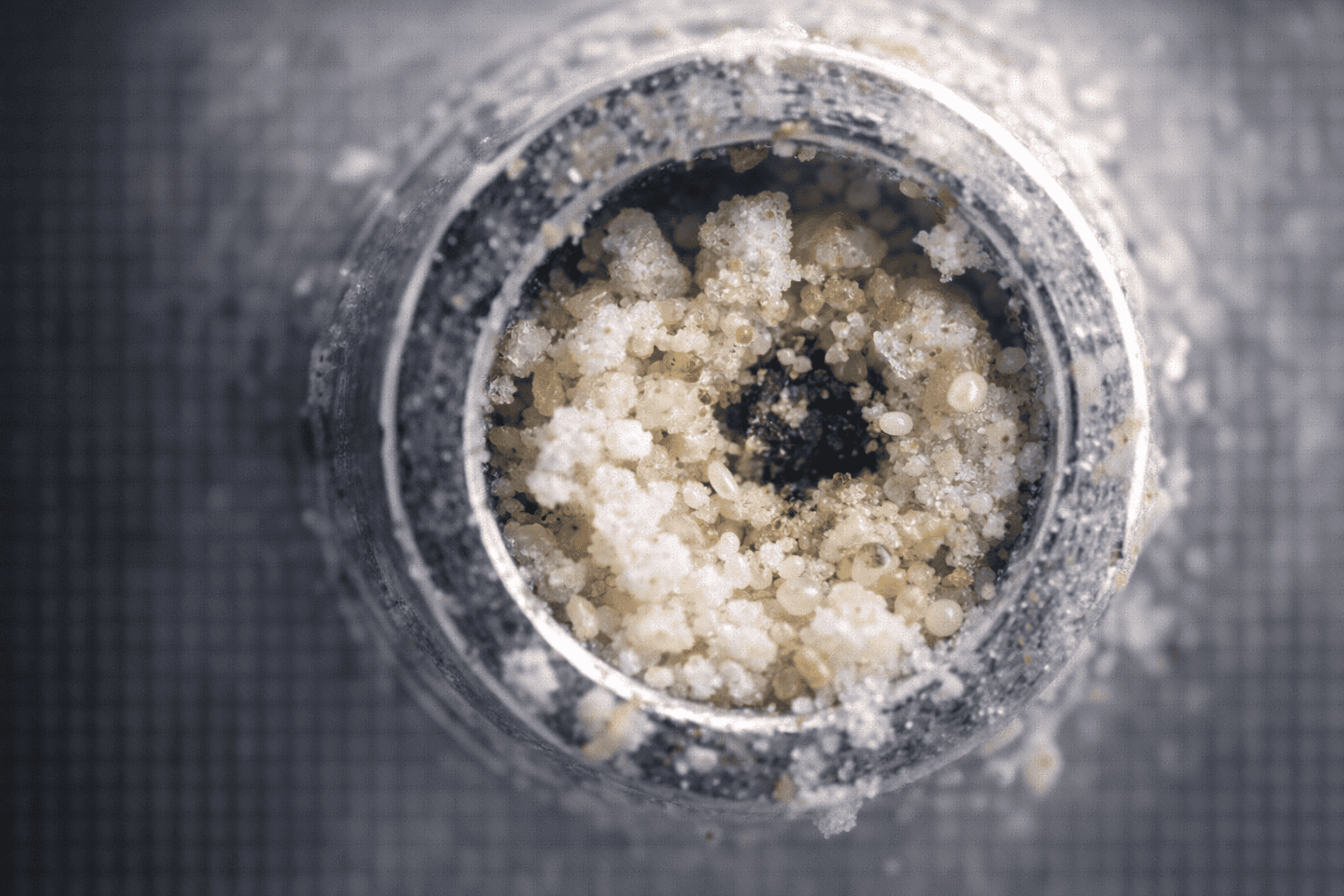

External factors like product crystallization and material degradation can cause failure over time. Some ingredients can dry and crystallize inside the nozzle between uses, while incompatible formulas can cause the plastic components themselves to degrade and break.

This is the long-term, real-world failure mode. The first issue is crystallization. Think about a sea salt spray. When the water evaporates, it leaves behind salt crystals. The same thing happens on a microscopic level in your spray nozzle. Between uses, the liquid in the nozzle orifice evaporates, leaving behind a tiny residue of the non-volatile ingredients. Over weeks and months, this residue builds up, forming a hard plug that blocks the spray. The second, more subtle issue is material degradation. The internal plastic components of the pump—the piston, the housing, the dip tube—are constantly bathed in your formula. If the plastic isn't 100% compatible with the chemicals in that formula, it can slowly become brittle, soft, or cracked. A plastic housing that becomes brittle can develop micro-cracks that let air in, killing the vacuum. A dip tube that softens can collapse on itself. This is why our process insists on full compatibility testing, where we submerge all pump components in the client's final formula for weeks under elevated temperatures to accelerate these effects and ensure the materials will remain stable for the entire life of the product.

Conclusion

A successful spray bottle is a perfect marriage of mechanical engineering and chemical compatibility. By selecting a high-quality pump engine and precisely matching it to your formula’s properties, you can prevent failures and deliver a perfect mist every time.

Written by

Mike Lee

You may also be interested in:

Why Are 50ml Spray Bottles the Best-Selling Size?

You're developing a new product and you're stuck on a critical decision: the bottle size.

Which Cap is Right for Your Spray Bottle: Overcap, Clip Lock, or Screw Cap?

You've spent months perfecting your formula and choosing the right spray pump. Now you need

Why Are Sunscreen Formulas So Tough on Packaging?

You've developed a brilliant sunscreen formula, but the packaging keeps failing. Bottles are turning yellow,

What Are the Best Sustainable Packaging Solutions for Sunscreen Brands?

You want to use sustainable packaging, but you're afraid it will fail. Choosing the wrong