PLA vs PP: Which Plastic is Right for Your Packaging?

September 22, 2025 • Mike Lee

You want to make a sustainable choice for your packaging, but you're also facing tight budgets. The world of plastics is confusing—is biodegradable really better, or is traditional plastic the smarter business decision?

PLA is a biodegradable plastic made from plants, ideal for brands appealing to eco-conscious markets. PP is a durable, versatile, and highly recyclable traditional plastic that offers a significant cost advantage. Your choice depends on brand values, budget, and target market.

I see this choice play out on our factory floor every week. One day, we are running a huge order of PP jars for a mass-market skincare brand that needs reliability and a low price point to stay competitive. The next, our team is carefully calibrating machines for a new line of PLA containers for an organic brand in California that built its entire identity on sustainability. Neither choice is wrong. They are just different tools for different jobs. The key is to understand which tool is right for you.

Is PLA plastic really biodegradable?

You've heard that PLA is "biodegradable," and you picture it disappearing into the earth like an apple core. This common misunderstanding can lead to making promises to your customers that aren't entirely true.

Yes, PLA is biodegradable, but only under specific industrial composting conditions. It requires high heat, humidity, and microbes found in commercial facilities to break down. It will not biodegrade in a landfill or your backyard compost bin.

The term "biodegradable" is where a lot of brands get into trouble. PLA (Polylactic Acid) is what we call a bioplastic because it's derived from renewable resources like corn starch or sugarcane. But its end-of-life is very specific.

The Truth About "Biodegradable"

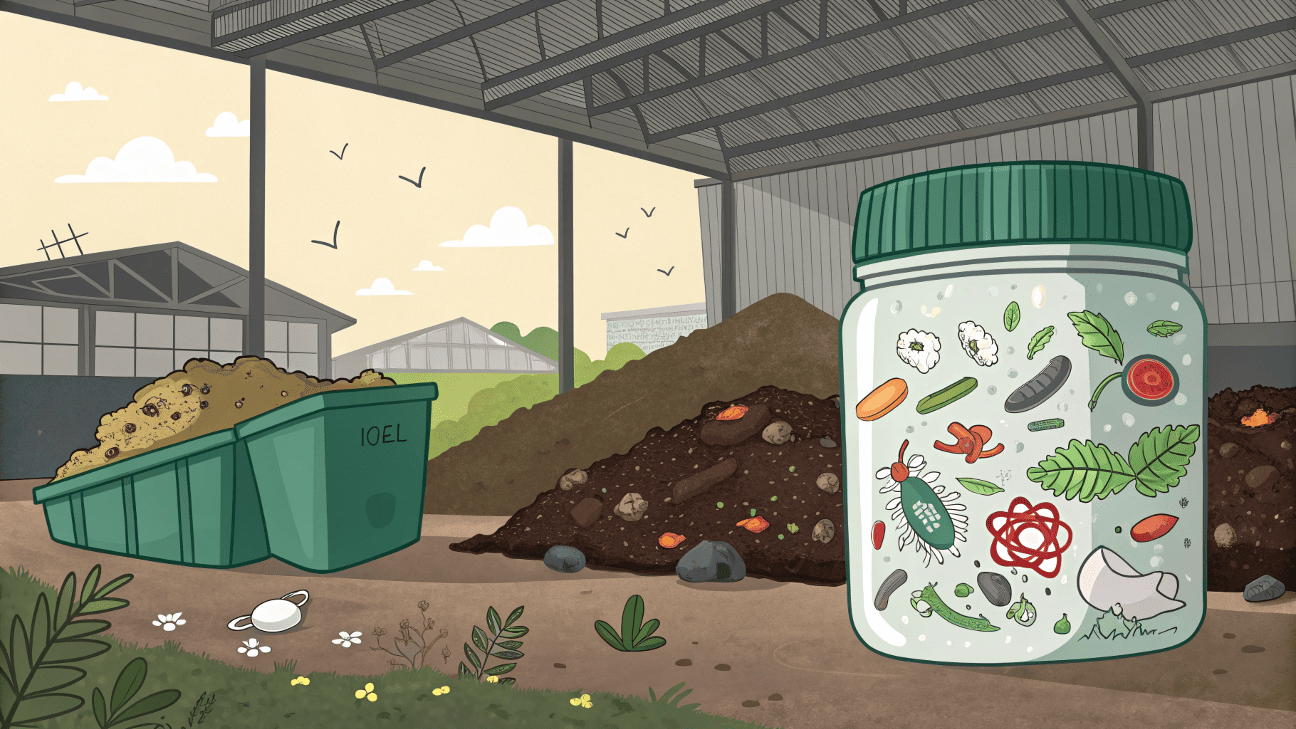

For PLA to break down, it needs to be sent to an industrial or commercial composting facility. These are controlled environments that maintain temperatures of over 140°F (60°C) and specific moisture levels. In this environment, microbes can break the PLA down into carbon dioxide, water, and organic biomass within about 90-180 days.

What Happens in Other Environments?

This is the critical part to understand. If a customer throws a PLA jar into their regular trash, it will end up in a landfill. A landfill is designed to be low in oxygen and moisture to prevent decomposition. Here, PLA will not biodegrade. It will sit there for hundreds of years, just like traditional plastic. It also won't break down in the ocean or a backyard compost pile, as they don't reach the required temperatures. So, choosing PLA carries a responsibility to educate your customers on how to dispose of it correctly.

What is the difference between PLA and traditional plastic?

You look at a clear PLA cup and a clear PP cup, and they seem almost identical. You wonder if the differences are big enough to justify the change in cost and material.

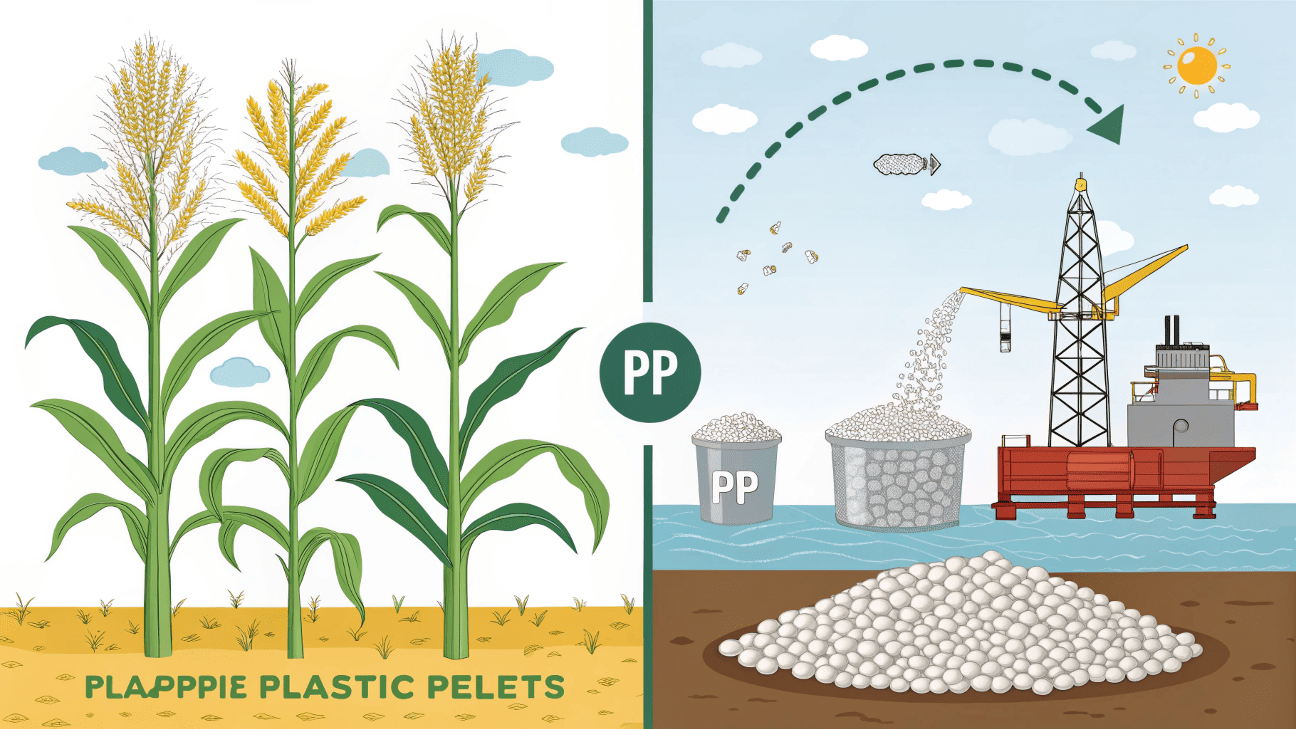

The main difference is the source material. PLA comes from renewable plants (like corn). Traditional plastics like PP (Polypropylene) come from non-renewable fossil fuels (oil and natural gas). This fundamental difference affects their cost, performance, and environmental impact.

When we talk about traditional plastic in cosmetic packaging, we are often talking about PP (Polypropylene). It's one of the most common materials we work with. Let's compare it directly to PLA.

A Head-to-Head Comparison: PLA vs. PP

| Feature | PLA (Polylactic Acid) | PP (Polypropylene) |

|---|---|---|

| Source | Renewable (corn, sugarcane) | Non-renewable (fossil fuels) |

| End-of-Life | Commercially compostable | Widely recyclable (Code #5) |

| Heat Tolerance | Low. Can warp above 110°F (43°C) | High. Can handle hot-fill processes |

| Durability | More brittle, lower impact resistance | Very durable, flexible, high impact resistance |

| Cost | Higher, can be 1.5x to 2x the cost of PP | Lower, very cost-effective |

| Best For | Cold products, brands with strong eco-story, markets with compost infrastructure | Hot-fill products, squeezable tubes, durable jars, cost-sensitive brands |

I had a client creating a face cream who wanted to use PLA. But their formula needed to be "hot-filled" into the jars at a high temperature. PLA would have warped and melted on the production line. We had to switch them to PP, which handles heat perfectly. This shows that the choice isn't just about your brand story; it's also about the technical requirements of your product.

What is the difference between biodegradable plastic and traditional plastic?

You hear "biodegradable" and "traditional" and think one is good and one is bad. The real picture is more complex, with major trade-offs in performance, cost, and real-world environmental impact for each.

The functional difference is in their end-of-life design. Biodegradable plastics are designed to be broken down by microbes. Traditional plastics are designed for durability and to be recycled into new plastic products.

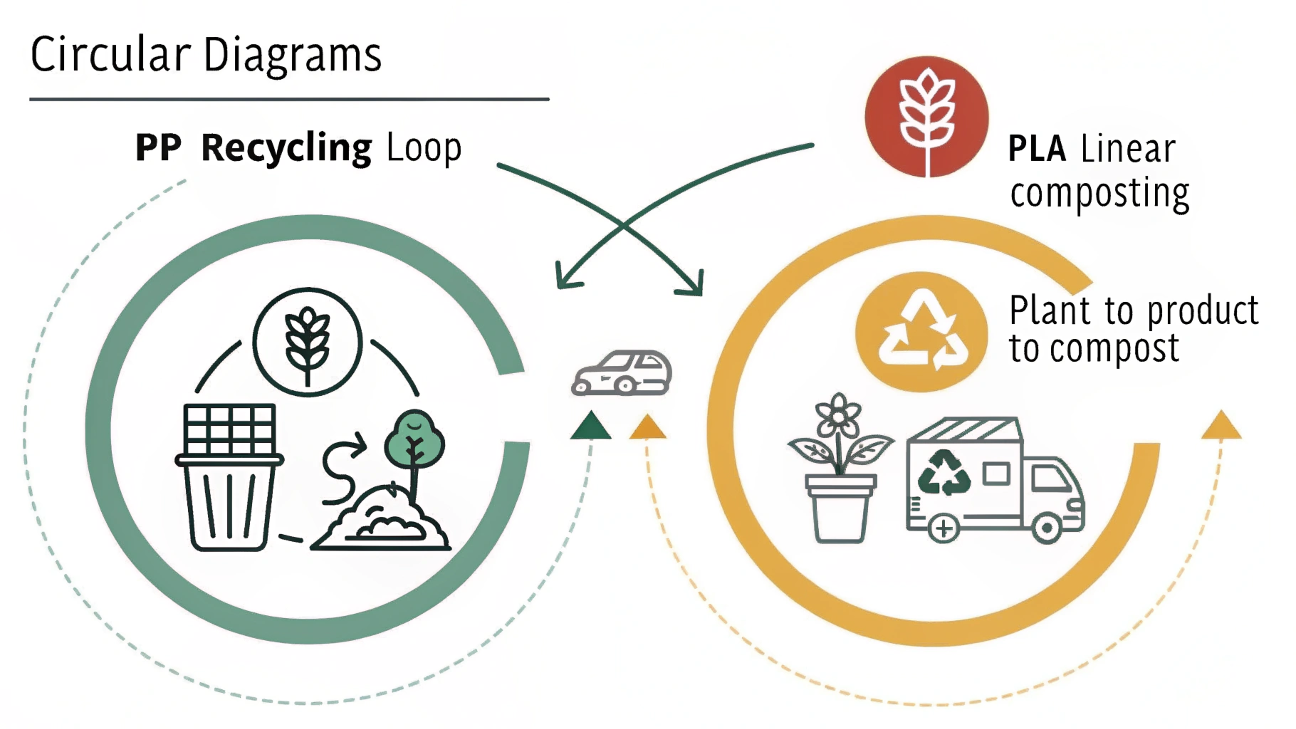

This is the core strategic choice a brand has to make. Are you designing for a circular economy of recycling, or an organic economy of composting?

The "Traditional Plastic" Lifecycle (Recycling)

Traditional plastics like PP and PET are incredibly efficient materials. They are lightweight, strong, and can be melted down and reformed into new products multiple times. This is the goal of the circular economy. The problem is that recycling rates are still low globally, and cross-contamination can reduce the quality of the recycled material. However, the infrastructure for recycling, while imperfect, is far more widespread than the infrastructure for composting PLA. For many regions, recycling PP is the most practical and environmentally sound option currently available.

The "Biodegradable Plastic" Lifecycle (Composting)

Biodegradable plastics like PLA offer a beautiful vision: a product that returns to the earth. This is a very powerful story for brands focused on "natural" and "organic" values. When disposed of correctly, PLA reduces the amount of plastic waste destined for recycling centers or landfills. The challenge is the "when disposed of correctly" part. It requires a specific system (industrial composting) that is not available in most cities. Without that system, its main environmental benefit is lost.

Conclusion

Choose PP for its durability, heat resistance, and cost-effectiveness, especially if recycling is your goal. Choose PLA for its plant-based origin and biodegradability to tell a powerful sustainability story, if your market supports commercial composting.

Written by

Mike Lee

You may also be interested in:

Why Are 50ml Spray Bottles the Best-Selling Size?

You're developing a new product and you're stuck on a critical decision: the bottle size.

Which Cap is Right for Your Spray Bottle: Overcap, Clip Lock, or Screw Cap?

You've spent months perfecting your formula and choosing the right spray pump. Now you need

Pump Doesn’t Work After 1–3 Months? The Real Reasons Spray Bottles Fail Over Time

You’ve launched a fantastic product with a fine mist sprayer, but after a few months,

Why Are Sunscreen Formulas So Tough on Packaging?

You've developed a brilliant sunscreen formula, but the packaging keeps failing. Bottles are turning yellow,