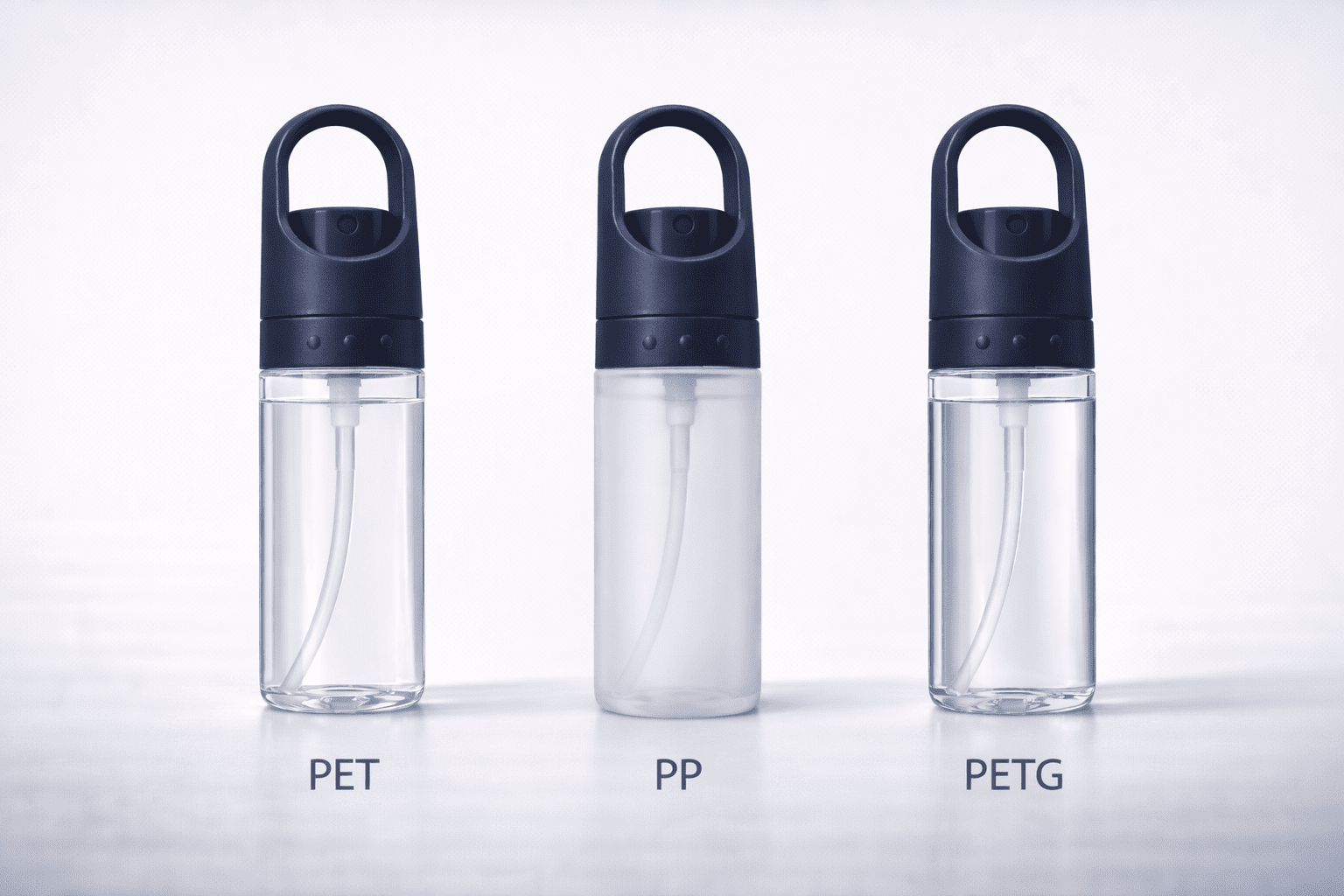

PET vs. PP vs. PETG Spray Bottles: Which Material Is Best for Your Product?

January 5, 2026 • Mike Lee

You see the acronyms PET, PP, and PETG, and they just look like a confusing alphabet soup. Choosing the wrong plastic could affect your product's look, safety, and cost, but you don't know where to start.

Choose PET for glass-like clarity and cost-effectiveness. Pick PP for its superior chemical resistance, ideal for oil-based formulas. Select PETG for a premium, ultra-durable bottle that combines the best qualities of both.

The choice of material feels technical, but it's really about matching the bottle to your brand's story. I recently worked with two clients at the same time. One was launching a simple, refreshing rosewater mist. We chose PET because its crystal clarity beautifully showcased the pure liquid inside, and it was very cost-effective for a mass-market launch. The other client was creating a luxury setting spray with special ingredients and a higher price point. For them, we used PETG. The extra durability and glass-like gloss of PETG gave the product a heavy, premium feel that justified the price. Same bottle shape, different materials, two totally different brand experiences.

Is PET a better choice than PETG plastic?

You want that premium, glass-like look, but you're also managing a budget. You hear PETG is "better" but worry you might be overpaying for features you don't actually need for your product.

PET is not better, but it is more cost-effective. It offers fantastic clarity for most applications. PETG is a premium upgrade, providing superior impact resistance and an even glossier, more glass-like finish, making it worth the extra cost for luxury products.

Think of it like choosing a seat on an airplane. PET is your business class seat—it's excellent, comfortable, and gets you where you need to go in style. It offers brilliant clarity, it's strong, and it's the industry standard for a reason. PETG is the first-class upgrade. It takes everything good about PET and enhances it. The "G" stands for Glycol-modified, and this modification makes the plastic even stronger and more impact-resistant, so it's less likely to crack if dropped. It also improves its clarity and gloss, giving it a truly luxurious feel. So, is PETG "better"? Only if your brand's identity and price point call for that first-class experience. For most products, the business-class comfort of PET is the perfect choice.

Should you choose PP or PET for your bottles?

You have a great product formula, but you're not sure if it's compatible with standard plastic bottles. You worry that your ingredients, like essential oils, could interact with the plastic over time.

Choose PET for its crystal clarity if you have a water-based product like a facial mist. Choose PP for its excellent chemical resistance if your product contains oils, solvents, or more aggressive active ingredients.

This choice is all about chemistry. PET and PP are both great materials, but they have different strengths. PET is the king of clarity. It's rigid, strong, and almost perfectly transparent, which is why it's the go-to material for beverages and most water-based cosmetics like toners and facial mists. Its job is to look good and be reliable. PP (Polypropylene), on the other hand, is the quiet workhorse. Its natural state is more translucent or "hazy" than PET, though it can be clarified. Its superpower is its chemical resistance. It doesn't react to most oils, solvents, or acids. This makes it the safest choice for products like aromatherapy sprays with high concentrations of essential oils, certain types of cleaners, or specialized serums. Think of PET as the beautiful window, and PP as the durable, protective wall.

What is the difference between PET and PP and PETG bottles?

You understand the individual materials, but you're having trouble seeing the big picture. You need a simple, clear comparison to help you make a final, confident decision for your brand.

PET is the clear, cost-effective standard. PP is the flexible, chemically-resistant specialist. PETG is the premium, ultra-durable hybrid that combines the clarity of PET with enhanced strength and gloss.

Let's put it all together. Your insight that there are no huge, essential differences is correct—they are all excellent, safe plastics. The choice is in the details that best fit your product and brand. Here is a simple breakdown to help you decide.

| Material | Key Feature | Best For | Think of it as... |

|---|---|---|---|

| PET | Crystal Clarity & Cost-Effective | Water-based facial mists, hairsprays, toners, mass-market products. | The industry standard. A reliable, high-quality material that looks great. |

| PP | Chemical Resistance & Flexibility | Products with essential oils, certain solvents, or aggressive ingredients. | The specialist. Protects your formula when other plastics might not. |

| PETG | Premium Durability & Gloss | Luxury skincare, serums, high-end brands wanting a glass-like feel. | The upgrade. Has the clarity of PET plus extra strength and a premium feel. |

Ultimately, you can't make a "wrong" choice, but you can make a "better" one. By considering your formula, your brand's price point, and the customer experience you want to create, you can confidently select the perfect material for your spray bottle.

Conclusion

Choosing between PET, PP, and PETG is about matching the material's strengths to your product's needs. Whether you need clarity, chemical resistance, or a premium feel, the right plastic will elevate your brand.

Written by

Mike Lee

You may also be interested in:

Why Are 50ml Spray Bottles the Best-Selling Size?

You're developing a new product and you're stuck on a critical decision: the bottle size.

Which Cap is Right for Your Spray Bottle: Overcap, Clip Lock, or Screw Cap?

You've spent months perfecting your formula and choosing the right spray pump. Now you need

Pump Doesn’t Work After 1–3 Months? The Real Reasons Spray Bottles Fail Over Time

You’ve launched a fantastic product with a fine mist sprayer, but after a few months,

Why Are Sunscreen Formulas So Tough on Packaging?

You've developed a brilliant sunscreen formula, but the packaging keeps failing. Bottles are turning yellow,