OEM/ODM Spray Bottle Projects: The Most Common Delays and How to Avoid Them?

February 4, 2026 • Mike Lee

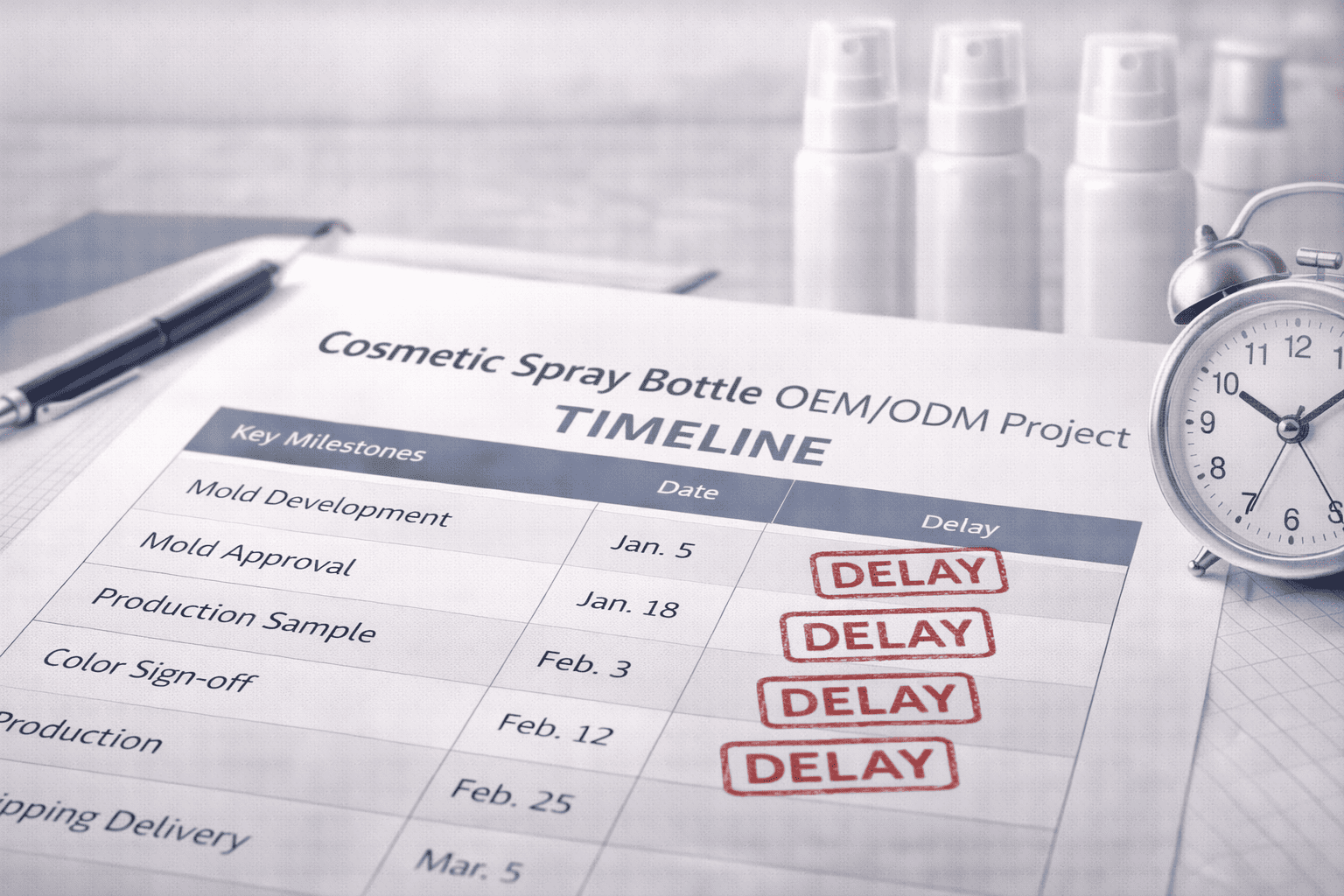

You’ve finally approved the plan for your new product line. The excitement is high, but then the process with your packaging supplier begins to drag. Weeks turn into months, your launch date is at risk, and you're getting vague answers about the cause of the hold-up.

The most common delays in OEM/ODM spray bottle projects stem from three predictable areas: an unclear initial brief, unexpected mold development issues, and endless back-and-forth revisions on color matching and artwork proofs.

I'll never forget a brand manager who came to us after a nightmare experience with another supplier. They were trying to launch a new line of body mists for the summer season. The project started in January with a six-month timeline. By May, they still didn't have a final, approved bottle. The problem was a chain reaction of small delays. The initial design file was missing key details, which led to a mold modification. Then, the custom color they wanted didn't match their Pantone chip, leading to three rounds of color samples. By the time they sorted it all out, they had missed the summer sales window. This is exactly the kind of costly, frustrating scenario we build our processes to prevent.

What is an OEM project, and how can it cause delays?

You have a unique, custom bottle design that is central to your brand's identity. You send the design to a factory to produce it, but the process gets bogged down in technical questions and misunderstandings.

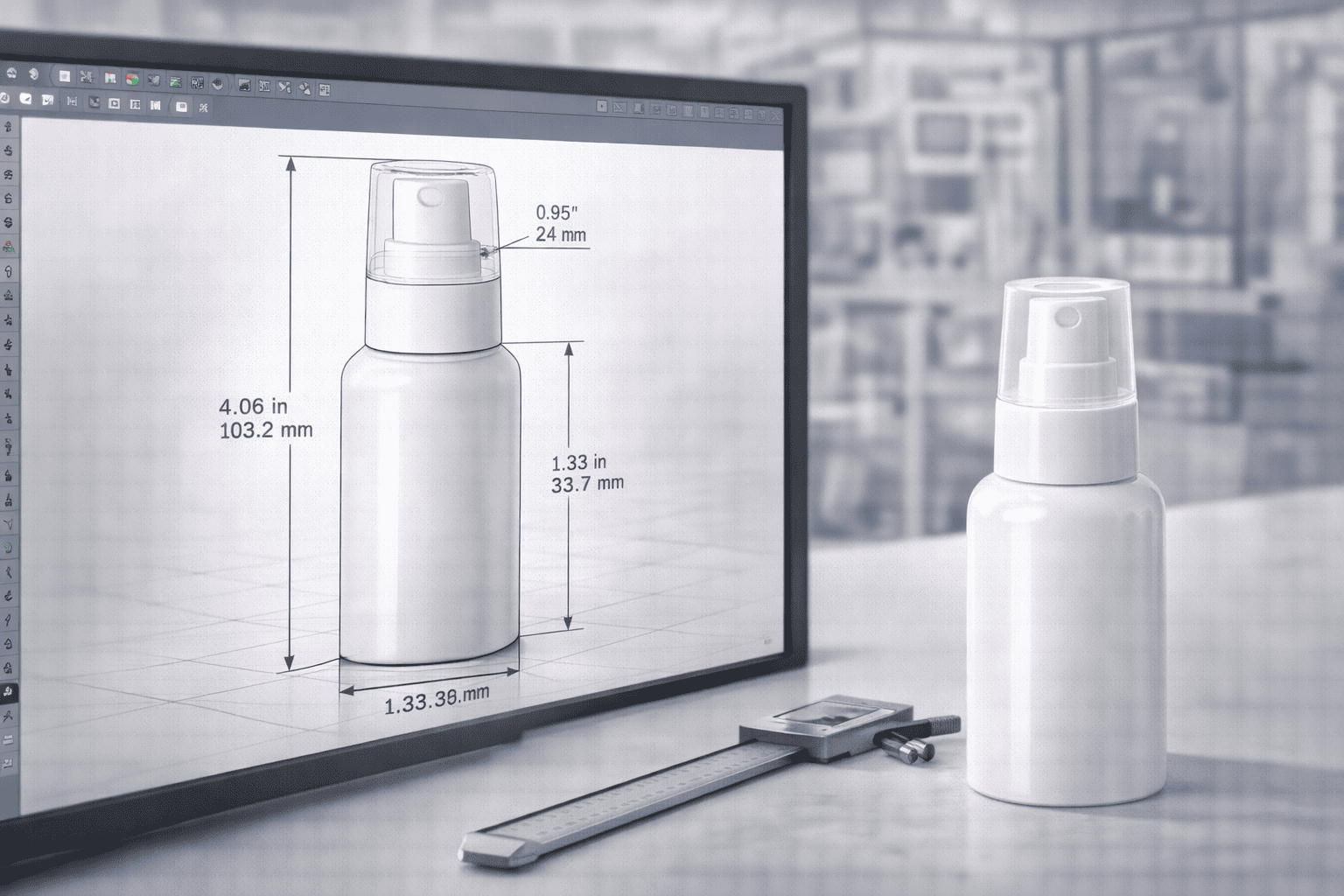

An OEM (Original Equipment Manufacturer) project is where you provide the complete design, and the factory builds it to your exact specifications. Delays happen when the initial design brief is incomplete, lacking the technical details needed for immediate mold production.

Think of an OEM project like giving an architect a blueprint to build your house. If the blueprint is just a sketch, the architect will have endless questions. It's the same in manufacturing. For an OEM project to run smoothly, we need more than just a picture. We need a detailed technical file, typically a 3D file like a .STP or .IGS. This file tells our engineers the exact dimensions, wall thickness, thread specifications, and surface curvatures. Delays are almost guaranteed when a client provides a vague brief. They might say, "I want a bottle like this one, but a little different." This forces us into a cycle of guessing, creating a sample, getting feedback, and revising. It's slow and inefficient. A clear brief, on the other hand, allows us to move directly to mold fabrication. This is why our project managers work with clients upfront to ensure their design files are production-ready before the clock even starts. This solves the cross-border communication issues that procurement directors like Shubihika often face.

OEM Brief: Vague vs. Clear

| Vague Brief Element | Why It Causes Delays | Rland's Clear Brief Requirement |

|---|---|---|

| "A 50ml bottle" | No dimensions or weight specified. | 3D file with precise height/width and target weight in grams. |

| "Make it in PET" | Doesn't specify grade or clarity. | PET, Grade A, with specific colorant/UV inhibitor requirements. |

| "Looks like this photo" | Lacks technical data for mold making. | Production-ready .STP or .IGS file. |

You need to get to market quickly, so you decide to use a bottle from a factory's existing catalog. It seems like the fastest path, but even small customizations end up taking weeks longer than you expected.

An ODM (Original Design Manufacturer) project is when you select a pre-existing bottle design from our catalog and customize it with your color and branding. The "hidden delay" often comes from underestimating the time required for these customizations.

The ODM process is your fast track, leveraging a mold that already exists. This is the first step you mentioned: choosing the mold/bottle shape. Because there's no mold to create, it should be simple, right? The delays creep in during the second and third steps of your insight: coloring and surface finishing. A client might say, "I want this bottle in our brand's signature blue." But "brand blue" can look different under different lighting and on different materials (like PET vs. PP). We must create a physical color sample (a "lab dip"), ship it for approval, and potentially revise it. This takes time. Similarly, approving the position, size, and technique (silk printing vs. hot stamping) for your logo requires creating digital mockups and then physical print proofs. Each revision cycle adds days or even weeks. For clients like Sani, who need to avoid long development cycles, we manage this by establishing all customization details upfront in a single, comprehensive brief and using our high-speed 3D printers to create realistic, colored mockups for faster initial approvals.

Why do color matching and artwork approval cause the biggest delays?

The bottle shape is approved. The mold is ready. You're on the home stretch, but you're stuck in a seemingly endless loop of rejecting color samples and revising artwork proofs.

Color matching and artwork approval are highly subjective and require physical samples for final sign-off. Delays are caused by mismatched expectations (e.g., screen color vs. plastic color) and inefficient communication loops during the revision process.

This stage is the number one cause of frustration and delay in my experience. The process you described—injection molding with color, then printing—is where art meets science, and that's where things get tricky. First, color. The color you see on your computer screen (an illuminated RGB color) will never look exactly the same as a physical Pantone color chip, which in turn will never look exactly the same as a colored plastic part that reflects light. Different plastic resins also take color differently. This "color gap" requires us to produce and ship physical samples for the client to approve in their own lighting conditions. If it's not a perfect match, the process repeats. Second, artwork. A logo might look perfect in a digital PDF proof, but when it's printed on a curved bottle surface, it can appear distorted. The position might be a millimeter too low. This again requires a physical sample for final approval. To avoid these delays, we insist on physical Pantone color codes from the start and provide clear guidelines for artwork submission, including distortion templates for curved surfaces. It’s about managing expectations and minimizing the number of revision cycles.

Conclusion

Avoiding delays in OEM/ODM projects comes down to one thing: clarity. A detailed initial brief, a clear understanding of the customization process, and a disciplined proofing system are the keys to a fast, efficient, and successful product launch.

Written by

Mike Lee

You may also be interested in:

How Will Sustainable Packaging for Skincare Mists Change by 2026?

You know your brand needs to be more sustainable, but the options are overwhelming. You

What Are the Top 5 Small Spray Bottle Trends for Skincare and Cosmetics in 2026?

Your new facial mist has a beautiful formula, but you're planning to use a standard

What Can We Learn from Market Leaders in Eco-Friendly Beauty Packaging?

You want your brand to be more sustainable, but the world of eco-friendly packaging is

How Can Packaging Design Make or Break Your Brand?

Your product formula is a masterpiece, but on the shelf, it's invisible. You're watching less