Leak-Proof Design: How Can You Choose Reliable Spray Bottles for Travel Products?

December 19, 2025 • Mike Lee

You've spent months perfecting your new travel-sized product. You imagine customers loving it on their vacation, but instead, you get an angry email with a photo of their ruined luggage, all because your bottle leaked.

To choose a truly leak-proof bottle, you must look beyond the cap. Focus on manufacturers who use high-precision molds, prove their quality with vacuum and drop testing, and select durable materials like PET or PP designed for stress.

This isn't just a hypothetical problem. A few years ago, a new brand wanted to launch a travel kit for a major airline. They sourced what looked like a great mini bottle from a low-cost supplier. During the airline's own product validation, over 20% of the bottles leaked under simulated cabin pressure. The deal was dead. They came to us, and we showed them our process—starting with the mold, moving to production controls, and finishing with our vacuum testing reports. They passed the airline's tests with a 0% failure rate. The secret isn't a better cap; it's a better process.

How can you make absolutely sure your travel bottles won't leak?

You screw the cap on tightly and assume it's secure. But you're forgetting that during travel, your bottle will be squeezed, dropped, and exposed to massive pressure changes in an airplane's cargo hold.

You must partner with a manufacturer who can prove their bottles are leak-proof through two critical tests: a vacuum leakage test to simulate flight pressure, and a drop test to simulate rough handling by baggage handlers.

A leak almost never starts with the cap. It starts with a tiny, invisible imperfection in the bottle's neck or threads. This imperfection comes from a poorly made or worn-out mold. A high-quality mold is the foundation of a leak-proof design. But even with a great mold, you must verify the final product. That's why we don't just hope for the best; we test for the worst. Any serious manufacturer should be able to provide you with reports on these two non-negotiable tests.

| Test Type | What It Simulates | Why It Is Essential for Travel Products |

|---|---|---|

| Vacuum Leakage Test | The low-pressure environment in an airplane cargo hold at 30,000 feet. This pressure difference tries to force air out, taking your product with it. | This is the #1 cause of leakage for products sold in airports or used by frequent flyers. Passing this test is mandatory. |

| Drop Test | A suitcase being thrown by a baggage handler, or a bottle falling off a hotel counter onto a hard floor. | This tests the bottle's structural integrity and the seal's ability to withstand sudden impact without cracking or popping open. |

What type of bottle design is best for travel?

You're looking at all kinds of cool, fancy bottle shapes. You're drawn to tall, skinny designs or unique geometric forms, but you're not thinking about how those shapes will handle the physical stress of travel.

For travel, the best bottle designs are compact, sturdy, and simple. Choose bottles with a wide base, thick walls, and a classic cylindrical or rounded shape, as these are inherently more resistant to being crushed, tipped, and broken.

Aesthetics are important, but for a travel product, function must come first. A bottle's physical shape has a direct impact on its durability. Tall, slender bottles have a high center of gravity and are easy to knock over. Complex shapes with sharp angles can create weak points in the plastic that are more likely to crack under pressure. When I consult with brands on travel products, I always guide them toward designs that prioritize stability. Think of it like building architecture: a skyscraper needs a massive, solid foundation to be stable. A travel bottle is no different. It needs a good base and strong, even walls to survive the journey.

What is the best and safest material for travel bottles?

You love the premium feel of glass, but you're terrified of it shattering in a customer's luggage. You're considering plastic, but you worry it feels cheap or might react with your product.

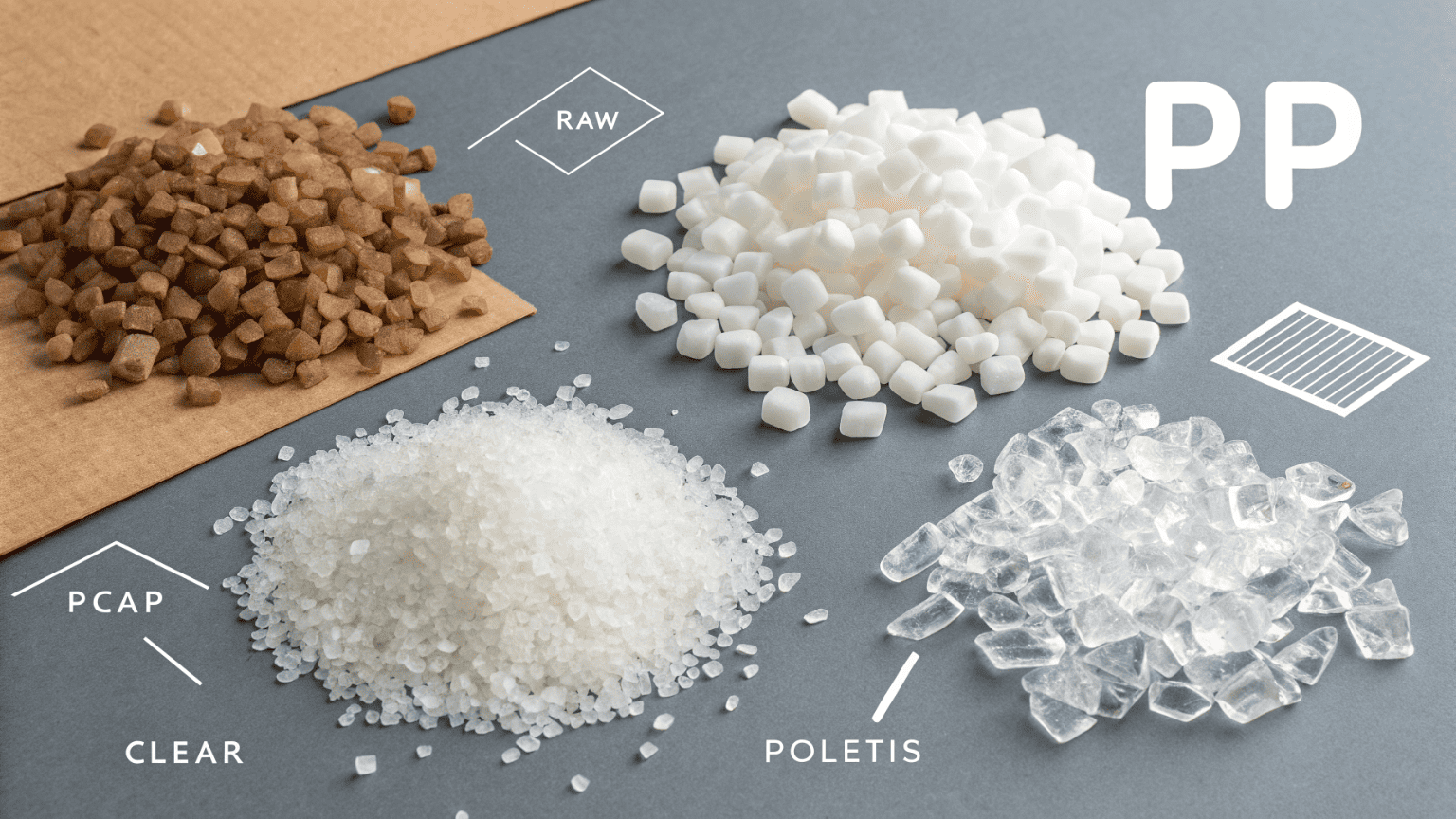

The best material for travel bottles is unquestionably plastic, specifically PET or PP. These materials offer the perfect balance of being lightweight, extremely shatter-resistant, and chemically compatible with most cosmetic formulas, ensuring both safety and reliability.

While glass is fantastic for luxury products that sit on a vanity, it is a liability for travel. No one wants to risk sharp shards of glass mixed in with their clothes. This is where modern plastics excel. They are not the cheap, flimsy plastics of the past. High-quality PET and PP are engineered for performance. They provide excellent clarity and can be molded into beautiful shapes, but their primary benefit for travel is their incredible durability. They can be squeezed, dropped, and jostled without breaking.

| Material | Durability (Shatter-Resistance) | Weight | Best Use Case for Travel |

|---|---|---|---|

| PET (Polyethylene Terephthalate) | Excellent | Lightweight | The go-to choice for most sprays, lotions, and gels due to its clarity and strength. |

| PP (Polypropylene) | Excellent | Lightweight | Often used for caps and for bottles containing formulas that are not compatible with PET. More flexible. |

| Glass | Poor | Heavy | Not recommended for travel products due to the high risk of shattering and its heavy weight. |

Conclusion

A leak-proof travel bottle is not a matter of luck. It's a result of deliberate engineering choices: a precision mold, a durable material like PET, and a manufacturer who proves their quality with vacuum and drop testing.

Written by

Mike Lee

You may also be interested in:

Why Are 50ml Spray Bottles the Best-Selling Size?

You're developing a new product and you're stuck on a critical decision: the bottle size.

Which Cap is Right for Your Spray Bottle: Overcap, Clip Lock, or Screw Cap?

You've spent months perfecting your formula and choosing the right spray pump. Now you need

Pump Doesn’t Work After 1–3 Months? The Real Reasons Spray Bottles Fail Over Time

You’ve launched a fantastic product with a fine mist sprayer, but after a few months,

Why Are Sunscreen Formulas So Tough on Packaging?

You've developed a brilliant sunscreen formula, but the packaging keeps failing. Bottles are turning yellow,