How Is rPET Revolutionizing the Cosmetic Packaging Industry?

November 12, 2025 • Mike Lee

You want to make your packaging more sustainable, but you're worried about sacrificing quality. You fear that "eco-friendly" materials might look cloudy, feel flimsy, or fail to protect your premium formula.

rPET is revolutionizing cosmetic packaging because it offers the clarity, strength, and performance of virgin PET plastic while drastically reducing waste, energy consumption, and your carbon footprint. It is sustainability without compromise.

Your insights on waste reduction, energy savings, and durability are the exact reasons we've become such strong advocates for rPET. I'll never forget a meeting with a luxury skincare brand founder. She was convinced that using recycled material would cheapen her brand's image. She pictured dull, greyish plastic. I didn't argue. Instead, I placed two bottles on the table in front of her. One was made from virgin PET, the other from high-quality rPET. They were indistinguishable. When I told her which was which, her entire perspective shifted. She realized she could uphold her brand's luxury aesthetic and fulfill her commitment to the environment. That's the power of rPET.

Why is rPET considered an eco-friendly choice for cosmetic packaging?

You hear "recycled plastic" and you know it's good for the environment, but you need the specific reasons. You want to confidently explain your choice to your team and your customers.

rPET is eco-friendly for four main reasons: it dramatically reduces landfill waste, it requires significantly less energy to produce, it lowers carbon emissions, and its durability prevents product waste.

rPET (recycled Polyethylene Terephthalate) isn't just a buzzword; its environmental benefits are measurable and significant. These advantages work together to create a much more sustainable system than relying on new, virgin plastics. The beauty of rPET is that it transforms a waste problem into a valuable resource, creating a circular economy where plastic bottles can be used again and again.

| The Four Core Benefits | Why It Matters for Your Brand |

|---|---|

| 1. Reduces Plastic Waste | By using rPET, you give a second life to existing plastic, keeping it out of landfills and oceans. This is a powerful and easy-to-understand story for your customers. |

| 2. Saves Energy | The process of recycling existing plastic into rPET uses up to 75% less energy than creating virgin plastic from raw petroleum. This is a massive reduction in your packaging's overall energy footprint. |

| 3. Lowers Carbon Footprint | Less energy consumption directly translates to fewer greenhouse gas emissions. Choosing rPET is a direct action your brand can take to combat climate change. |

| 4. Is Strong & Durable | rPET maintains the excellent strength and shatter-resistance of virgin PET. This protects your product, reduces breakage during shipping, and minimizes waste from damaged goods. |

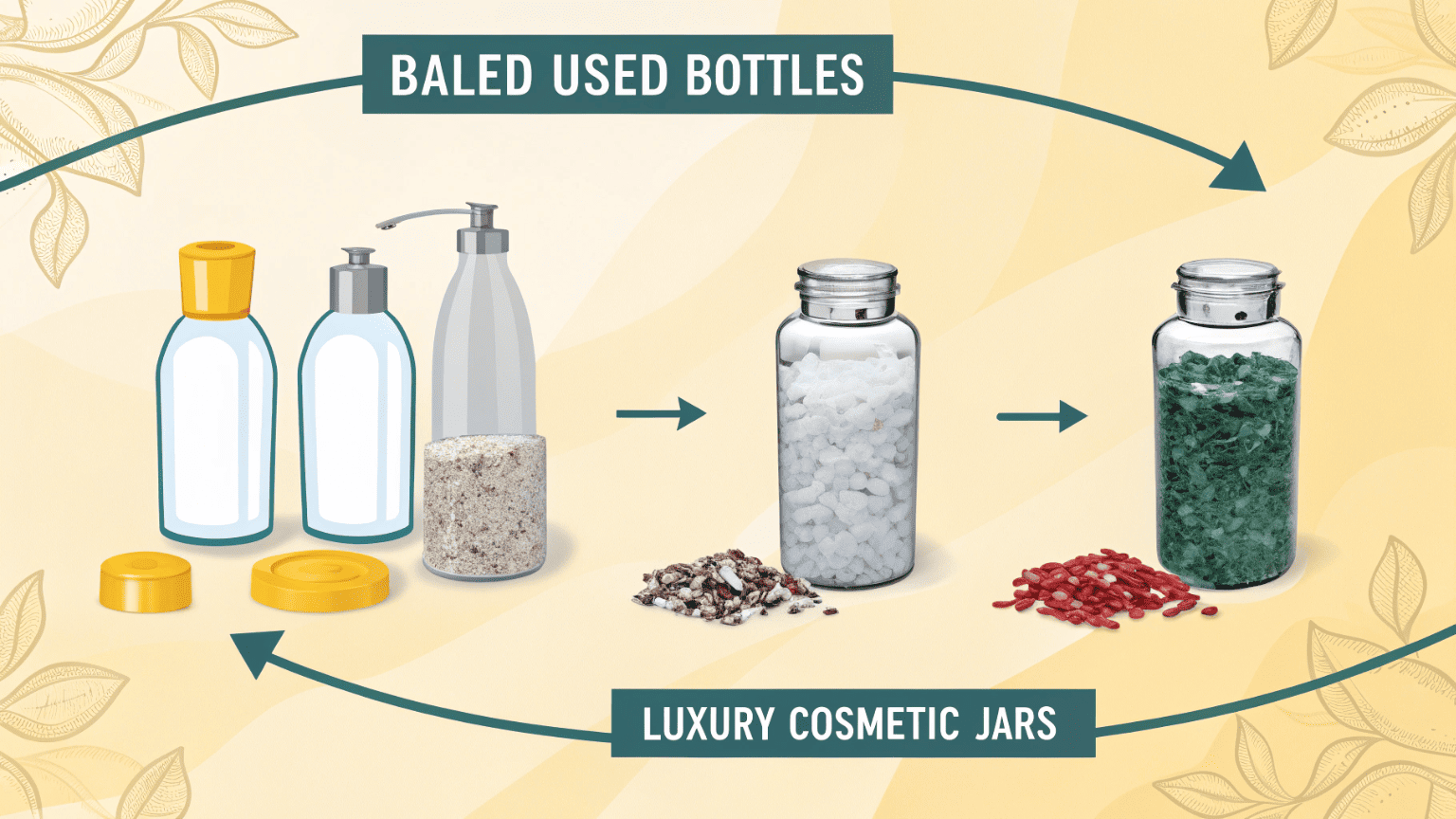

How does the mechanical rPET process actually work?

The term "recycled resin" sounds complex and industrial. You want to understand how a used water bottle actually becomes the beautiful, clear jar that holds your cosmetic cream.

Mechanical recycling is a physical process that sorts, shreds, and melts used PET plastic into reusable pellets called "rPET resin." It doesn't chemically alter the plastic, making it a highly efficient way to give it a second life.

The term "mechanical recycling" just means we're using machines to physically process the plastic, not chemicals to break it down. It’s a beautifully simple and effective system that is revolutionizing how we see plastic waste. At our facility, the process is straightforward and quality-controlled at every step.

The Journey from Bottle to Bottle:

- Collection & Sorting: It all starts when consumers recycle PET bottles. These are collected and sent to a recycling facility where they are sorted by color to ensure the final rPET is clear.

- Shredding & Washing: The sorted bottles are then shredded into small flakes. These flakes go through a rigorous washing and cleaning process to remove any labels, caps, and contaminants. This step is crucial for achieving high-purity, cosmetic-grade material.

- Melting & Pelletizing: The clean, dry flakes are melted down and extruded into long spaghetti-like strands. These strands are cooled and chopped into tiny pellets. These pellets are the final rPET resin, ready to be used.

- Molding: We take these rPET pellets and use them in our injection molding or blow molding machines, just as we would with virgin plastic, to create new, beautiful, and durable cosmetic packaging.

How are rPET jars and bottles shaping the future of packaging?

You see the benefits, but you wonder if rPET is just a temporary solution. You want to invest in a material that is not just sustainable today, but is part of the long-term future of your industry.

rPET jars and bottles are shaping the future by proving that sustainability and premium quality are not mutually exclusive. They are creating a scalable, circular economy for plastic, making it the new standard for responsible brands.

The future of sustainable packaging is not about finding some magical, yet-to-be-invented material. It's about perfecting and scaling the systems that we know work right now. rPET is at the forefront of this movement. Its biggest impact is that it is changing mindsets. Brands are realizing they don't have to choose between their environmental values and their business goals.

The Future rPET Is Creating:

- A New Standard of Quality: High-grade rPET is so clear and performs so well that it's becoming the expected standard, not the alternative. Brands who stick with 100% virgin PET will soon have to explain why.

- Driving a Circular Economy: The more brands demand rPET, the more valuable post-consumer plastic becomes. This strengthens the entire recycling infrastructure, encouraging better collection and processing globally.

- Consumer Demand: Today's consumers are savvy. They actively look for brands that use recycled materials. Packaging made from rPET is no longer just a feature; it's a powerful marketing tool that communicates shared values and builds trust.

Choosing rPET is an investment in a proven, scalable, and desirable future for your brand and the planet.

Conclusion

rPET is revolutionizing cosmetics by offering a path to true sustainability without compromise. It reduces waste, saves energy, and delivers the strong, premium packaging that modern brands and consumers demand.

Written by

Mike Lee

You may also be interested in:

Is Your Eco-Friendly Sunscreen Packaging Actually Green, or Just Greenwashing?

Your brand wants sustainable sunscreen packaging. But using unverified eco-materials can lead to leaks and

How Can Smart Packaging Choices Reduce Your Carbon Footprint?

You're committed to making your brand more environmentally friendly, but the term "carbon footprint" feels

How Do You Create a Truly Sustainable Cosmetic Packaging Strategy?

You feel the pressure to make your packaging sustainable, but every choice seems complex. Switching

Is PLA the Future of Sustainable Beauty Packaging?

You're seeing "plant-based plastic" and "compostable" everywhere. You're intrigued by PLA as a way to