How Are Global Regulations Changing the Cosmetic Packaging Market?

September 14, 2025 • Mike Lee

You want to sell your products globally, but you're drowning in a sea of regulations. You fear a small packaging mistake could get your entire product line banned in a key market.

Global regulations, especially from the EU, are forcing a massive shift towards sustainability and safety. This means stricter rules on plastic use, mandatory recycled content, and proof that your packaging materials won't contaminate your product, directly impacting design and material choices.

Working at Rland, I'm on the front lines of this change. The conversations I have with brands are no longer just about bottle shapes. They are about compliance. A brand from India might have a perfect product for France, but if their packaging doesn't meet EU standards, it's a non-starter. These regulations aren't just red tape; they are fundamentally reshaping what cosmetic packaging can and must be. My job is to help our partners navigate this complex landscape so they can succeed.

How Big Is the Cosmetic Packaging Market?

You see packaging everywhere, but you wonder about the real scale of the industry. You feel small and unsure how to compete in such a massive and crowded space.

The global cosmetic packaging market is enormous, valued at over $50 billion and growing. This massive size means huge opportunities but also intense competition, where compliance with new regulations is becoming a key differentiator for success.

The sheer size of this market can be intimidating, but it also shows how much opportunity there is. The growth isn't just about selling more lipstick; it's driven by new trends and demands that create openings for smart brands.

Key Growth Drivers

I see two main forces pushing the market forward:

- The Rise of Indie and Niche Brands: The market is no longer dominated by just a handful of giants. Social media has enabled smaller brands to build loyal followings. These brands are often more agile and are leading the charge on trends like sustainability and unique designs, pushing manufacturers like us to offer more flexible and innovative solutions.

- E-commerce Expansion: Online sales demand packaging that is not only beautiful but also durable enough to ship. It also needs to be "Instagrammable." The unboxing experience is part of the product, and brands are investing heavily in packaging that creates a memorable first impression.

The Impact of Regulations on this Growth

Regulations are channeling this growth in a specific direction. For example, the huge demand for single-use samples is now bumping up against new rules designed to reduce plastic waste. As a manufacturer, this forces us to innovate. We are actively working on refillable sample systems and mono-material sachets that meet regulations without sacrificing the customer experience. This is how the market evolves.

Why Are Cosmetic Products Sold in the EU Regulated by EU Cosmetic Regulations?

You want to enter the lucrative EU market, but the rules seem overly complicated. You don't understand why a package that's fine in your home country needs a complete redesign for Europe.

The EU operates as a single market. EU cosmetic regulations ensure a consistent, high level of safety for all consumers across member states. This harmonization means one set of rules applies, simplifying trade within the EU but creating a strict entry barrier.

I explain this to clients almost every week. The "why" is crucial. The EU's goal is to protect its 450 million consumers with one uniform standard. If a product is safe in Germany, it should be safe in Spain. This principle is good for consumers, but for brands outside the EU, it can feel like a fortress.

The Packaging and Packaging Waste Regulation (PPWR)

This is the big one right now. It's the EU's main tool for tackling waste, and it directly impacts cosmetic packaging. It's not just a suggestion; it's becoming law. As a packaging producer, we are constantly updating our processes to meet these changing rules.

Here are the key points I emphasize to brands looking to enter the EU:

- Recycled Content: The PPWR sets mandatory minimums for the amount of recycled plastic (like rPET) that must be in new plastic packaging. We are sourcing more and more PCR materials to help our clients meet these targets.

- Recyclability: By 2030, all packaging must be designed to be recyclable. This is pushing a huge trend towards mono-material design, where the bottle and cap are made from the same plastic to make recycling easy.

- Waste Reduction: The regulation aims to reduce the overall amount of packaging. This means saying goodbye to unnecessary boxes, inserts, and layers. It forces a minimalist approach.

This isn't just an EU issue. Many other regions, like California, are adopting similar rules. The EU is simply setting the global standard.

What Is the Cosmetic Product Safety Regulation?

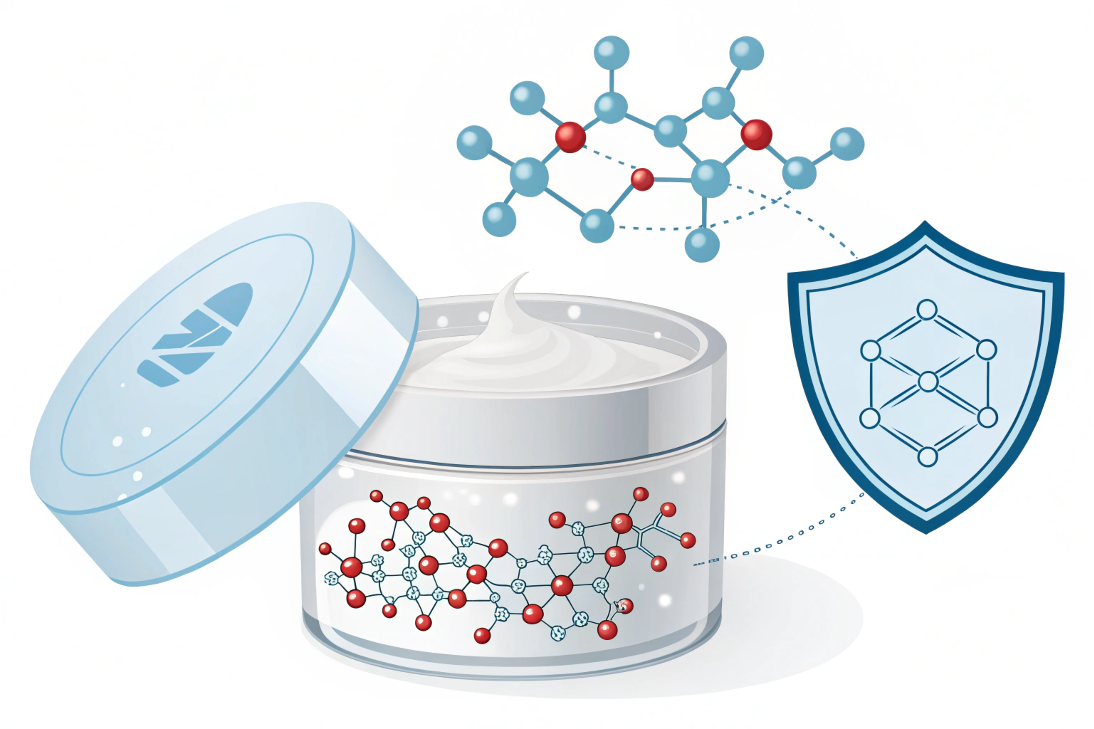

You focus on making your formula safe. You assume that as long as the cream or serum is fine, the bottle it comes in doesn't really matter from a safety perspective.

Cosmetic product safety regulations cover both the formula and the packaging that comes into direct contact with it. The rules ensure that no harmful substances can "migrate" from the plastic or glass into the product, protecting the consumer.

This is a critical detail that many brands overlook. The bottle is not just a container; it's legally part of the cosmetic product itself. The concern is chemical migration. Certain plastics can release trace amounts of substances over time, especially when exposed to heat or certain ingredients.

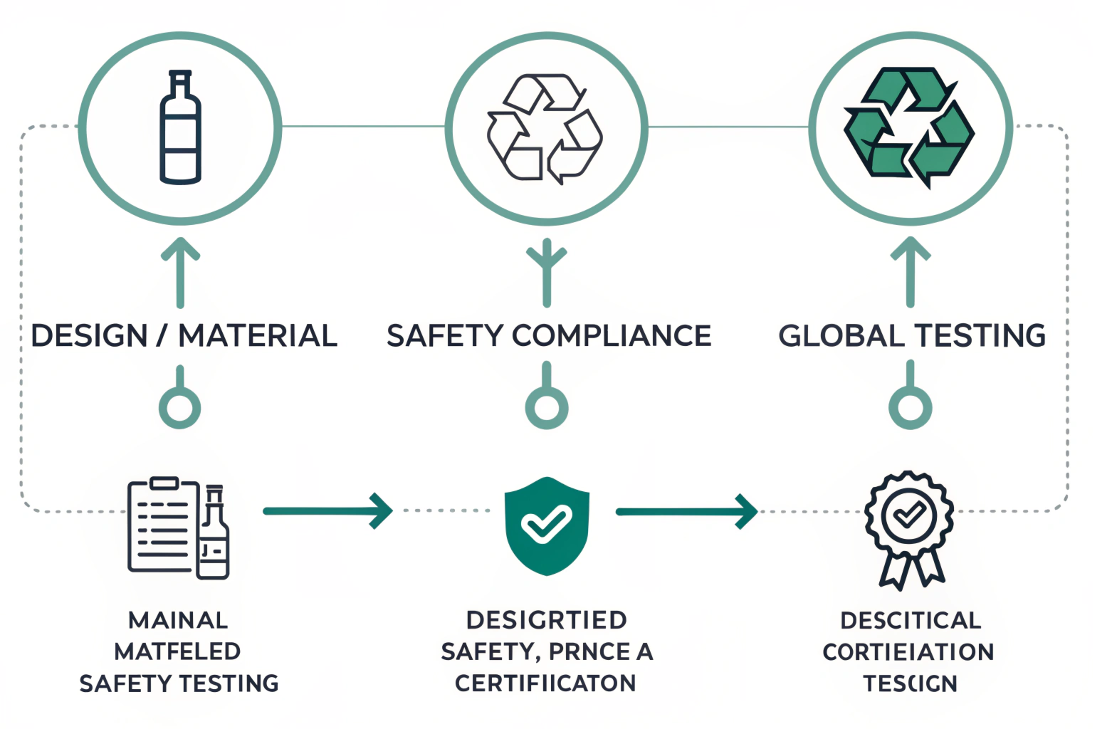

Ensuring Material Safety

At Rland, we take this very seriously. Our quality assurance is built around preventing this.

- Material Selection: We guide clients to choose the right type of plastic or glass based on their formula. For example, some essential oils are very aggressive and require a specific grade of PET or glass to prevent interaction. We often recommend using FDA-grade or food-grade materials, as they have already passed stringent migration tests.

- Traceability: This is non-negotiable for any brand that is serious about safety and global sales. We provide full-process monitoring and documentation. This means we can trace a finished bottle all the way back to the specific batch of raw plastic pellets it was made from.

- Certifications: Our ISO 9001 certification isn't just a piece of paper. It's a system that governs our entire production process, ensuring that every step, from R&D to delivery, meets strict quality and safety standards.

When a regulator asks for your safety dossier, you need to have this information about your packaging ready. A reliable manufacturing partner provides this documentation as part of the service.

| Regulatory Concern | Rland's Solution | Benefit to Brand |

|---|---|---|

| Recycled Content Mandates | Sourcing high-quality PCR materials | Meets EU and other regional laws. |

| Recyclability Rules | Expertise in mono-material design | Future-proofs your packaging. |

| Material Migration | Material safety consulting & traceability | Ensures product safety and compliance. |

Conclusion

Global regulations are not a barrier; they are a guide to creating safer, more sustainable products. By understanding these rules and partnering with a knowledgeable manufacturer, you can build a future-proof brand.

Written by

Mike Lee

You may also be interested in:

OEM/ODM Spray Bottle Projects: The Most Common Delays and How to Avoid Them?

You’ve finally approved the plan for your new product line. The excitement is high, but

Why Are 50ml Spray Bottles the Best-Selling Size?

You're developing a new product and you're stuck on a critical decision: the bottle size.

Which Cap is Right for Your Spray Bottle: Overcap, Clip Lock, or Screw Cap?

You've spent months perfecting your formula and choosing the right spray pump. Now you need

Pump Doesn’t Work After 1–3 Months? The Real Reasons Spray Bottles Fail Over Time

You’ve launched a fantastic product with a fine mist sprayer, but after a few months,